| –

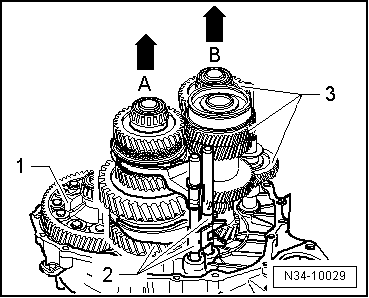

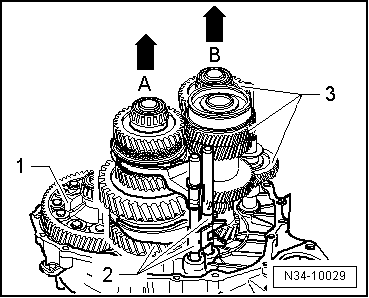

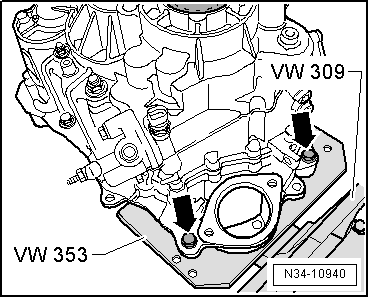

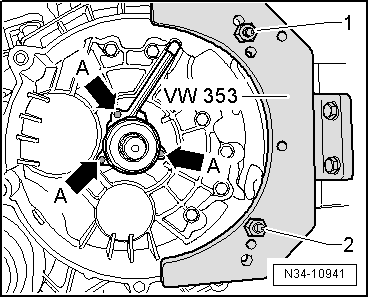

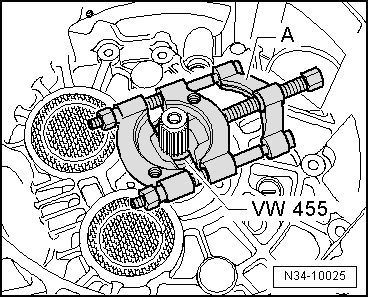

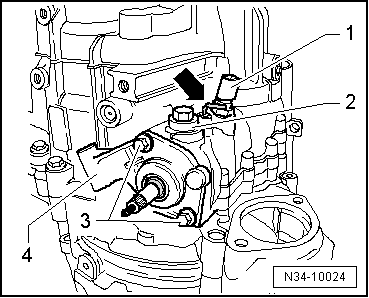

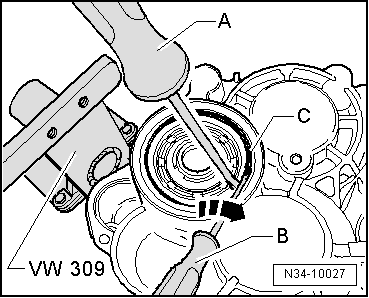

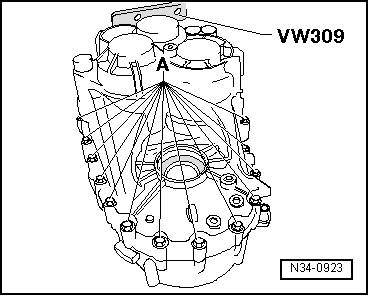

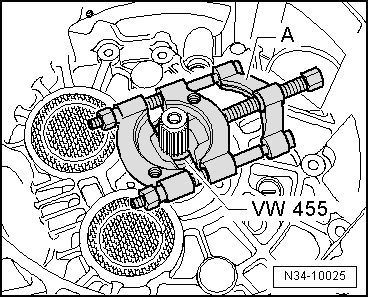

| With left hand, raise differential -1-. With right hand, lift output shaft for 1st to 4th gear together with selector rods -2--arrow A-. |

| –

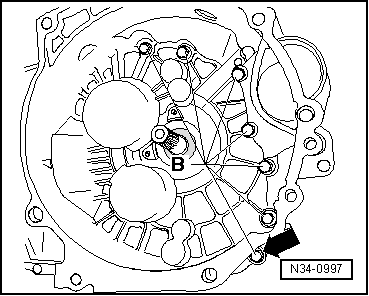

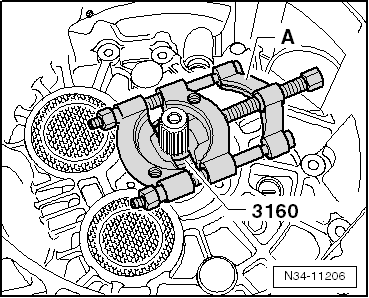

| At the same time, the second mechanic must lift the input shaft, reverse shaft and 5th/6th gear output shaft -3- out of the clutch housing together with the selector rods -arrow B-. |

Note | After shafts are lifted, differential may be set back in clutch housing if desired. |

| –

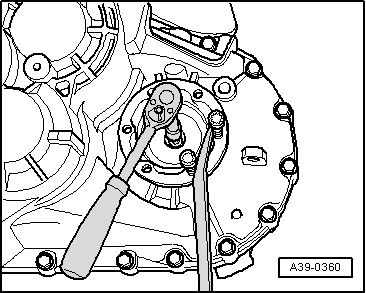

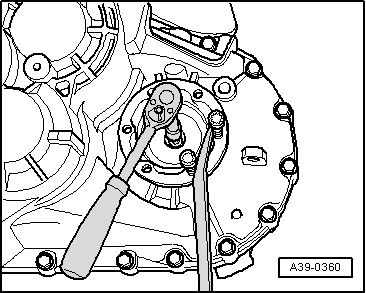

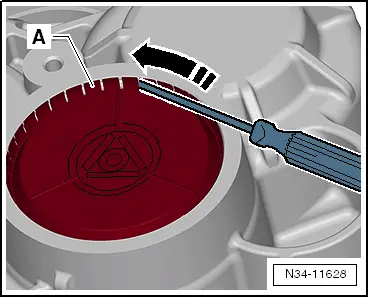

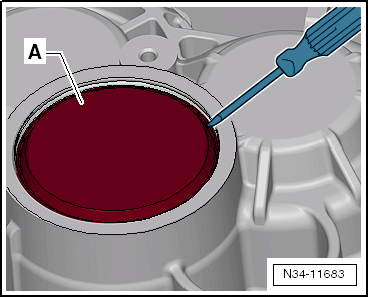

| Lever out seal for input shaft using lever -VW 681-. |

Note | Always renew grooved ball bearing on input shaft → Item. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note