Leon Mk1

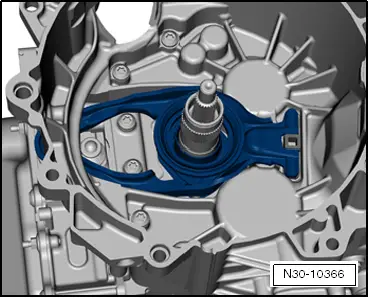

| Overview of clutch actuation: |

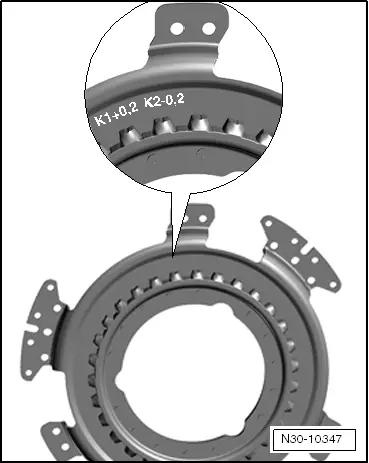

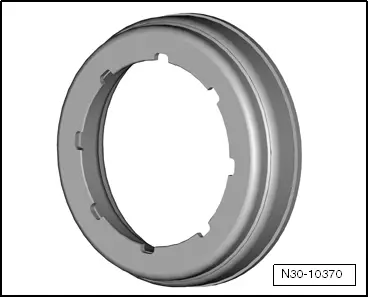

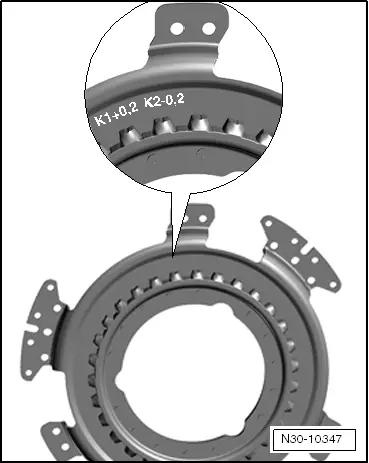

| 1 - | Shim for „K 1“ |

| q | → Chapter „Adjusting position of clutch engagement bearings K 1 and K 2“ |

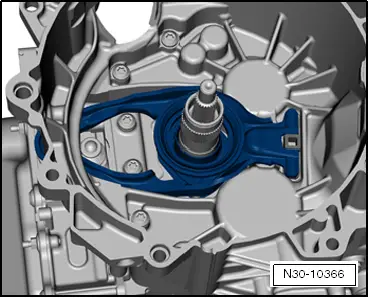

| 2 - | Large engaging lever for „K 1“ |

| q | With engagement bearing |

| 3 - | Mounting |

| q | For large engaging lever „K 1“ |

| q | Is not renewed |

| 4 - | Small engagement bearings for „K 2“ |

| 5 - | Shim for „K 2“ |

| q | → Chapter „Adjusting position of clutch engagement bearings K 1 and K 2“ |

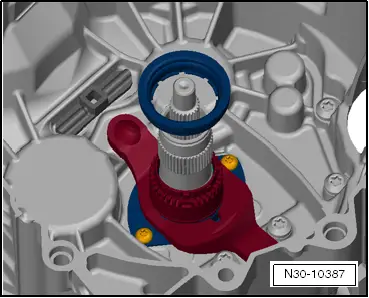

| 6 - | Upper section of bushing |

| q | Small small engaging lever „K 2“ |

| q | Is removed and installed together with lower section of bushing |

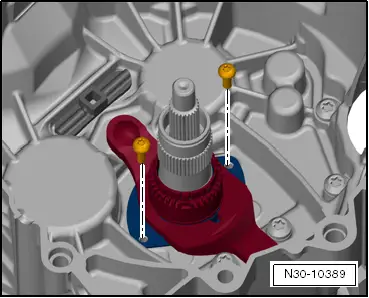

| 7 - | Small engaging lever for „K 2“ |

| q | Is removed and installed together with upper and lower section of bushing |

| 8 - | Ball head stud |

| q | Small small engaging lever „K 2“ |

| q | → Chapter „Adjusting position of clutch engagement bearings K 1 and K 2“ |

| 9 - | Bolts |

| q | 8Nm + 90° |

| q | Always replace. |

| 10 - | Lower section of bushing |

| q | Small small engaging lever „K 2“ |

| q | Is removed and installed together with upper section of bushing |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

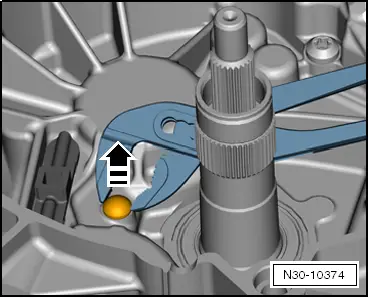

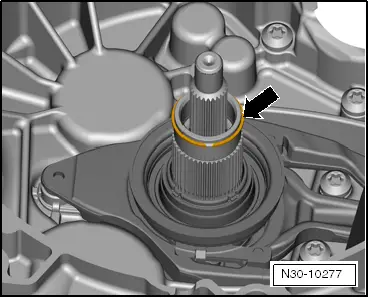

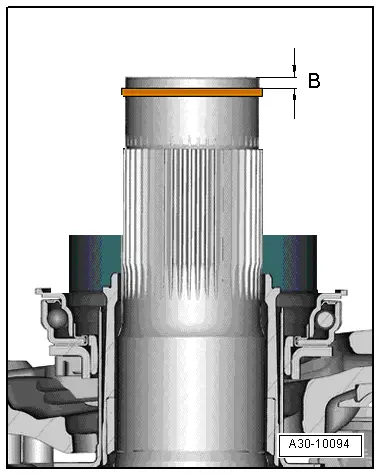

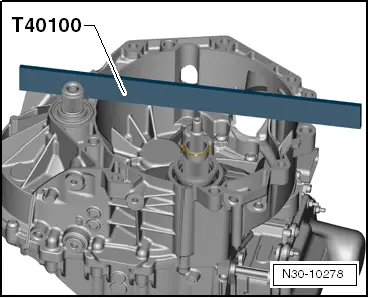

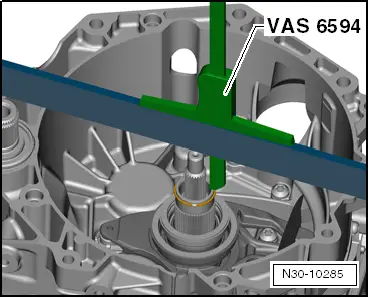

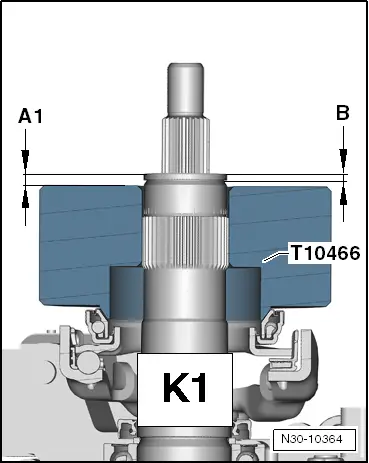

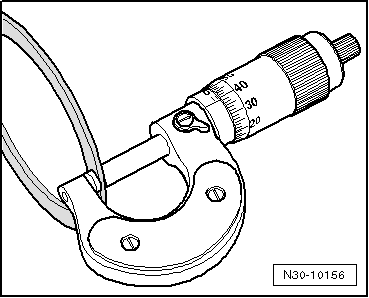

| Dimension „A 1“ | |

| – | Dimension „B“ |

| = | Actual height tolerance of clutch engagement bearing „K 1“ |

|

Note

Note

|

|

| Height tolerance of engagement bearing „K 1“ | |

| –/+ | Clutch tolerance of clutch „K 1“ |

| = | Calculated thickness of shim „SK 1“ |

|

|

|

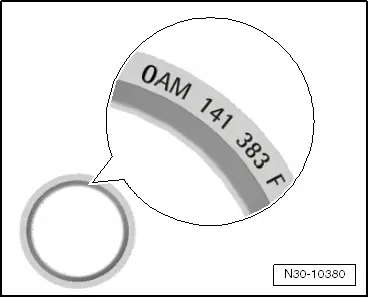

| Calculated thickness of shim mm | Available shims Thickness in mm | Part number of shim |

| 1,21 … 1,60 | 1,50 | 0AM 141 383 |

| 1,61 … 1,80 | 1,70 | 0AM 141,383 A |

| 1,81 … 2,00 | 1,90 | 0AM 141,383 B |

| 2,01 … 2,20 | 2,10 | 0AM 141 383 C |

| 2,21 … 2,40 | 2,30 | 0AM 141 383 D |

| 2,41 … 2,60 | 2,50 | 0AM 141 383 E |

| 2,61 … 2,80 | 2,70 | 0AM 141 383 F |

| 2,81 … 3,00 | 2,90 | 0AM 141 383 G |

| 3,01 … 3,20 | 3,10 | 0AM 141 383 H |

| 3,21 … 3,40 | 3,30 | 0AM 141,383 J |

| 3,41 … 3,80 | 3,50 | 0AM 141,383 K |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

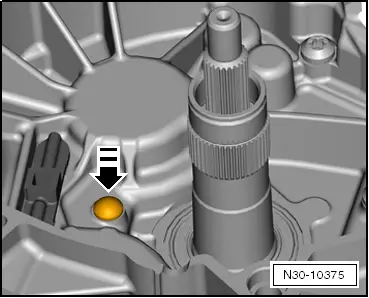

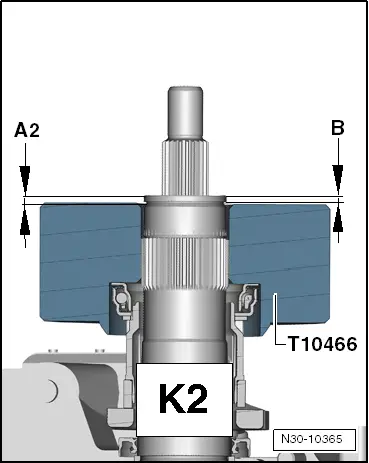

| Dimension „A 2“ | |

| – | Dimension „B“ |

| = | Actual height tolerance of clutch engagement bearing „K 2“ |

|

Note

Note

|

|

| Height tolerance of engagement bearing „K 2“ | |

| –/+ | Clutch tolerance of clutch „K 2“ |

| = | Calculated thickness of shim „SK 2“ |

|

|

|

| Calculated thickness of shim mm | Available shims Thickness in mm |

| 0,31 … 0,90 | 0,80 |

| 0,91 … 1,10 | 1,00 |

| 1,11 … 1,30 | 1,20 |

| 1,31 … 1,50 | 1,40 |

| 1,51 … 1,70 | 1,60 |

| 1,71 … 1,90 | 1,80 |

| 1,91 … 2,10 | 2,00 |

| 2,11 … 2,30 | 2,20 |

| 2,31 … 2,50 | 2,40 |

| 2,51 … 2,70 | 2,60 |

| 2,71 … 3,30 | 2,80 |

|

Caution

Caution WARNING

WARNING