Leon Mk1

|

| Special tools and workshop equipment required |

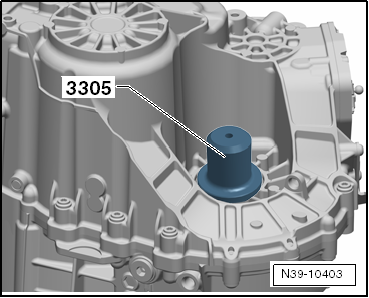

| t | pressure tool -3305- |

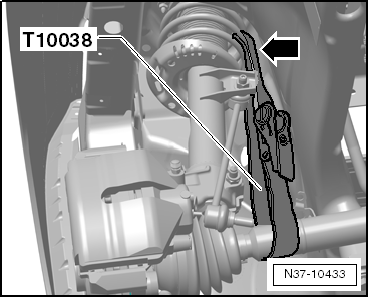

| t | Tensioning tool -T10038- |

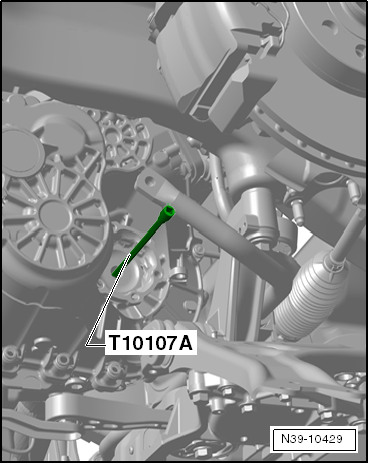

| t | Socket and key -T10107 A- |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | Torque wrench -V.A.G 1332-, see equivalent → Anchor. |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|