| t

| The Tiptronic does not work - Gear change not possible: Check the locking disc of the support bracket for selector lever cable in the top part of the gearbox |

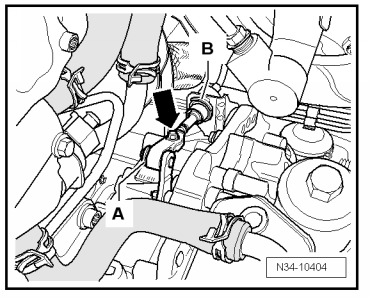

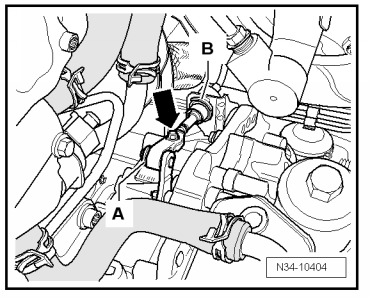

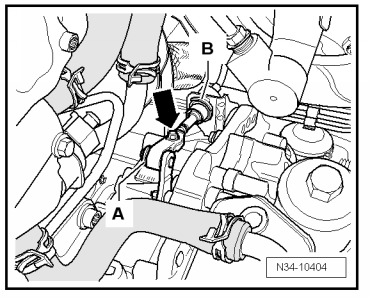

Note | If the »correct voltage« is no longer at hand, undo the locking -B-. The -arrow- points in the direction of the adjustment screw of the control cable. |

| t

| Insufficient »drive« - Possible oil deficiency: Only fill oil after the → Anchor„Oil level check and troubleshooting“. |

| t

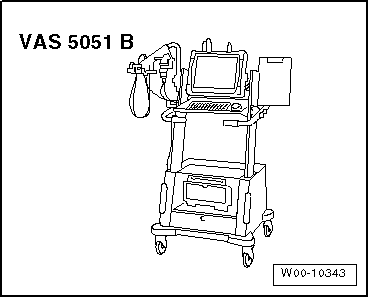

| No fault found. As a matter of experience, it is common that the gearbox is made responsible for »faults« that are caused by other components or units. There were some cases that a faulty behaviour of the gearbox occurred that had been triggered by a defective air supply to the engine. Such mistakes must be avoided at all costs. If this type of fault is already exempted, under certain circumstances work can be carried out using the testing equipment from SEAT. |

| t

| Error at hand: First the meaning of the registered fault has to be understood. The testing equipment of SEAT includes the function Guided Fault Finding. When used correctly, the Guided Fault Finding allows a large number of faults to be detected. |

| t

| Presence of a fault »not caused on the gearbox side«: If, for example, the gearbox registers a fault that the „ABS Signal Missing“ and there may be another controller that specifies that the „ABS Signal Missing“, one can assume that this cannot lead to the gearbox being »faulty«. This entry only means that the gearbox (and possibly another controller)is waiting to receive a signal via the data bus that, however, is not arriving. In this case, it is more than likely that the controller for the ABS is faulty. For this reason, the mechatronic control unit for the DSG automatic gearbox -J743- should not be removed without cause. In this example, the fault indicated a problem with the ABS system. |

| t

| If the oil sump has been removed or if gear oil is needed, do not start the engine or tow the vehicle. |

| t

| After replacing the gearbox, verify the gearbox oil level → Chapter and complete if necessary. Level quantities and specifications → Chapter. |

| t

| Thoroughly clean unions and adjacent areas before removing. |

| t

| When assembling check that fitting sleeves are correctly positioned. |

| t

| O-rings, flanges and gaskets should always be replaced. |

| t

| After removing gaskets, check the contact surfaces of the casing and shaft for feathering or damage caused by the removal process. |

| t

| Always replace paper gaskets, completely disposing of the used gasket and thoroughly cleaning the contact surfaces. |

| t

| In order to fit flanges apply gear oil around the outer edge and on the sealing lip. |

| t

| Coat the O-rings with gear oil or Vaseline before fitting to avoid crushing during assembly. |

| t

| Never use other lubricants in the gear oil area. Otherwise there is a danger of operation faults in the hydraulic gear mechanism. |

| t

| The open side of the seals should face the liquid to be retained. |

| t

| After assembly, check the level of the gear oil and top up if necessary: → Chapter. |

| t

| Do not over expand the securing rings; replace them if necessary. |

| t

| Securing rings must be well seated in the groove. |

| t

| The bolts are removed in reverse order to the tightening sequence. |

| t

| If no tightening sequence is specified, nuts and bolts used to fix covers and casings should be tightened and loosened in stages and in diagonal pairs. |

| t

| Renew self-locking nuts. |

| t

| The thread of bolts threaded with a fixing agent should be cleaned using a wire brush. Next, position the bolts with AMV 185 101 A1. |

| t

| Specified torques given are for unlubricated nuts, bolts and screws. |

|

|

|

Note

Note

Note

Note