| t

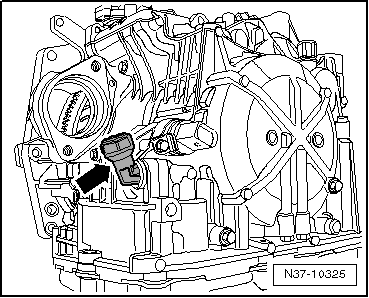

| Before fitting the radial oil seals, fill the space between the sealing lips with grease |

| t

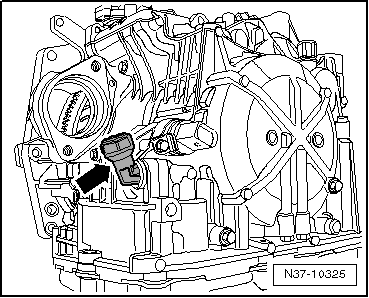

| After fitting, check the ATF fluid level and top up if necessary |

| t

| Note the use-by date of the sealant. |

| t

| After applying the sealing paste, bolt up the components within 5 minutes |

| t

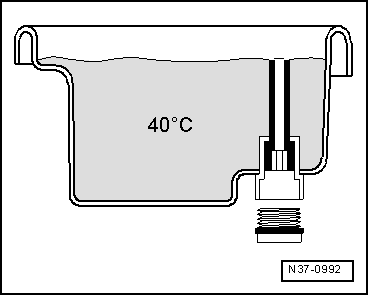

| After assembly, the sealant should be dry in approx. 30 minutes Then fill with ATF |

| t

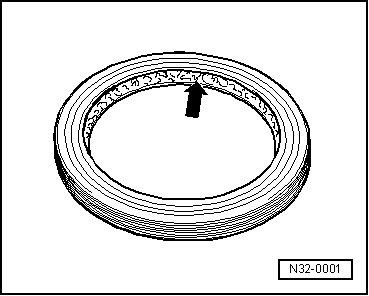

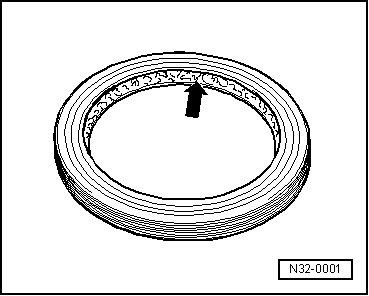

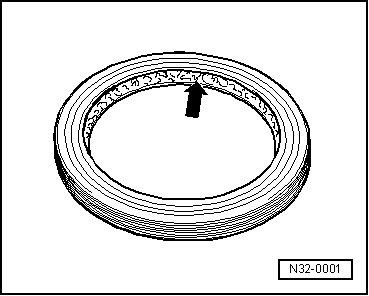

| Do not over-stretch the securing rings, replace if necessary |

| t

| The securing rings must be perfectly seated in their groove |

| t

| The bolts or washers for fastening the covers and boxes should be loosened and tightened in diagonal pairs |

| t

| Particularly sensitive parts should not be placed on their sides, such as the slide box, for example, and should be loosened and tightened in diagonal pairs |

| t

| Tightening torques are specified for nuts and bolts without lubrication |

| t

| If the bolt threads have remains of locking paste, clean with a wire brush. Next insert the bolts using → Spare Parts Catalogue |

| t

| Always replace self-locking nuts following their removal |

| t

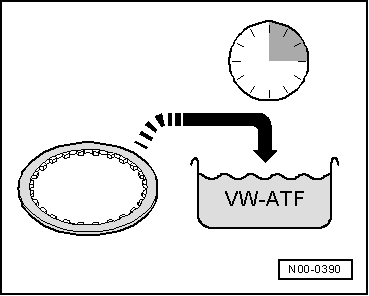

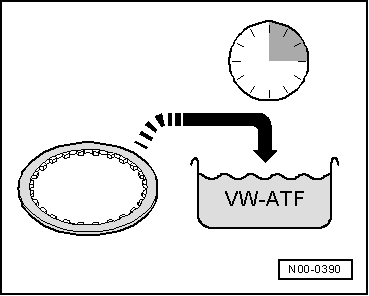

| Fit bearings on the gearbox using ATF |

| t

| Mount the pin axial bearings in the correct position → Chapter |

| t

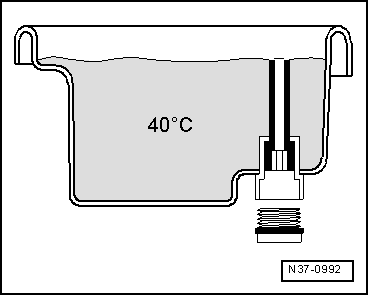

| Heat the inner / roller bearing ring to 100ºC before press fitting |

| t

| Do not swap interior and exterior rings of bearings of the same size. |

| t

| Replace conical roller bearings on one shaft at the same time Where possible, replace with the same make |

| t

| Do not open excessively when removing or fitting |

| t

| Measure the adjustment washers at various points using a micrometer. Different tolerances make it possible to precisely determine the thickness of the washer required |

| t

| Check for notches or wear Only fit shims in perfect state |

| t

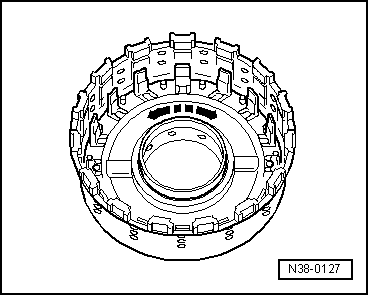

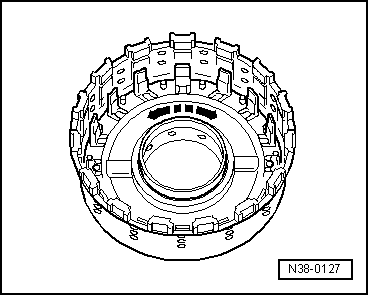

| The K1, K2 and K3 must be dismantled for cleaning while identifying the defective parts (for example the external rings and the internal rings) according to the replacement identification letters. |

| t

| Before fitting the piston, coat the sealing lips and oil seals with ATF |

|

|

|