Leon Mk1

|

|

|

|

|

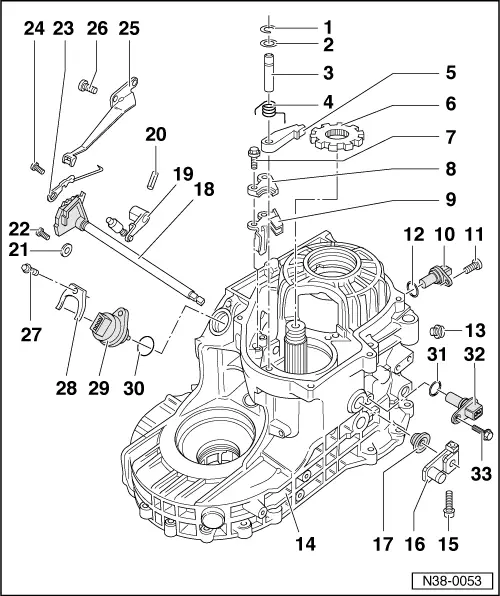

| t | Output gear must be removed for dismantling and assembling parking lock → Chapter „Removing and installing drive shaft“. |

| 1 - | Circlip |

| q | Always renewing. |

| 2 - | Washer |

| 3 - | Shaft for detent lever |

| q | Is secured by circlip and bearing cap of drive shaft. |

| q | Depending on design, with groove for circlip. |

| 4 - | Return spring |

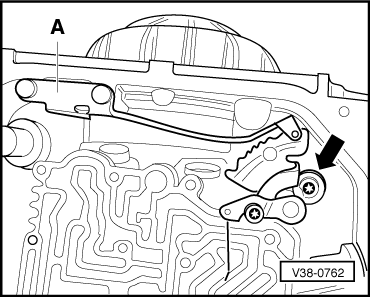

| q | Installing → Fig.. |

| 5 - | Detent lever |

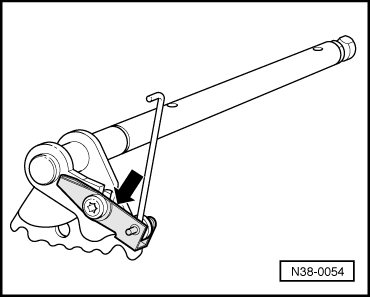

| q | Inserting with return spring → Fig.. |

| 6 - | Parking lock gear |

| q | Rounded side faces teeth of drive shaft. |

| 7 - | Bolt, 14 Nm |

| 8 - | Support plate |

| q | Installing → Fig.. |

| 9 - | Guide plate |

| q | Inserting before supporting plate → Fig.. |

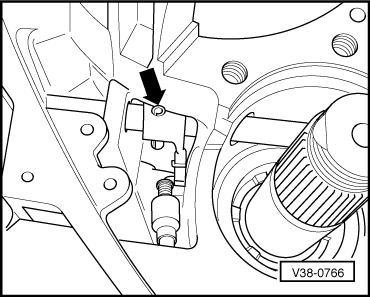

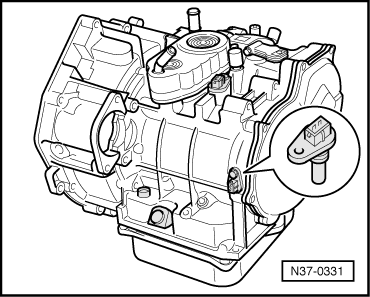

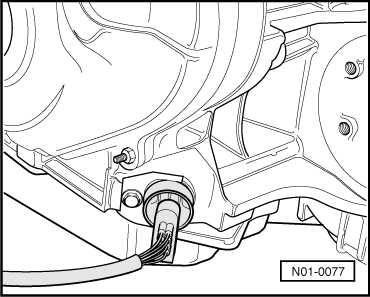

| 10 - | Vehicle speed sender -G68- |

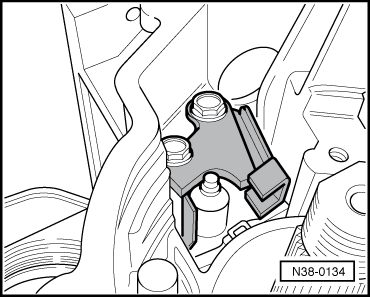

| q | Removing and installing → Fig.. |

| q | Is checked by self-diagnosis in vehicle → Self-diagnosis for automatic gearbox 099 - 4-speed; Rep. Gr.01. |

| 11 - | Bolt, 10 Nm |

| 12 - | O-ring |

| q | Always renewing. |

| 13 - | Bolt, 15 Nm |

| q | With oil seal. |

| q | Always renewing. |

| 14 - | Gearbox housing |

| 15 - | Bolt, 10 Nm |

| 16 - | Lever |

| q | For selector shaft. |

| 17 - | Oil seal |

| q | Levering out with screwdriver. |

| q | Driving in flush with -VW 423-. |

| 18 - | Selector shaft with selector segment and detent segment |

| q | Inserting together with engaging lever. |

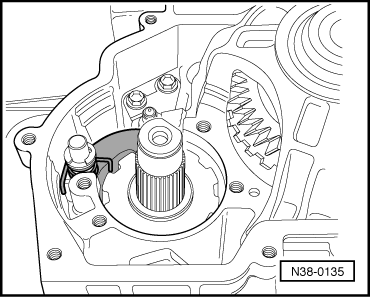

| q | Removing and installing → Fig.. |

| 19 - | Engaging lever |

| q | Inserting together with selector shaft and detent segment. |

| 20 - | Spring pin |

| q | Driving in after inserting engaging lever → Fig.. |

| q | Driving out with a drift. |

| 21 - | Lock washer |

| q | Removing and installing → Fig.. |

| 22 - | Bolt, 10 Nm |

| 23 - | Spool valve control |

| q | Adjusting → Chapter, removing and installing valve body. |

| 24 - | Bolt, 10 Nm |

| 25 - | Spring for selector segment |

| 26 - | Bolt, 10 Nm |

| 27 - | Bolt, 10 Nm |

| 28 - | Retainer |

| q | For multi-function switch. |

| 29 - | Multi-function switch -F125- |

| q | Removing and installing → Fig.. |

| q | Is checked by self-diagnosis in vehicle → Self-diagnosis for automatic gearbox 099 - 4-speed; Rep. Gr.01. |

| 30 - | O-ring |

| q | Always renewing. |

| 31 - | O-ring |

| q | Always renewing. |

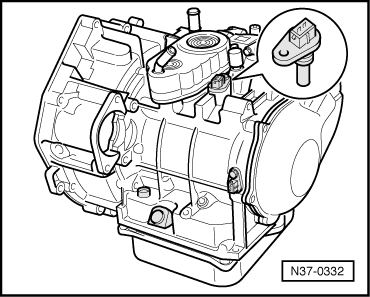

| 32 - | Gearbox speed sender -G38- |

| q | Removing and installing → Fig.. |

| q | Is checked by self-diagnosis in vehicle → Self-diagnosis for automatic gearbox 099 - 4-speed; Rep. Gr.01. |

| 33 - | Bolt, 10 Nm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|