|

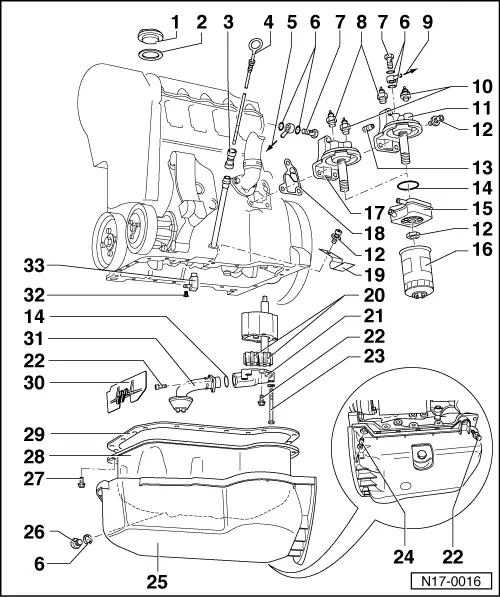

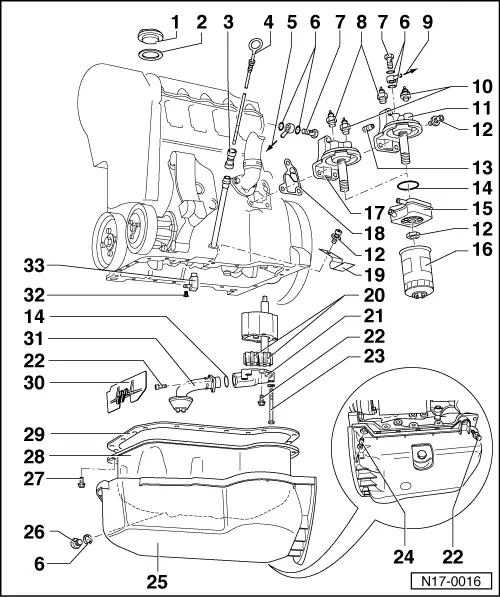

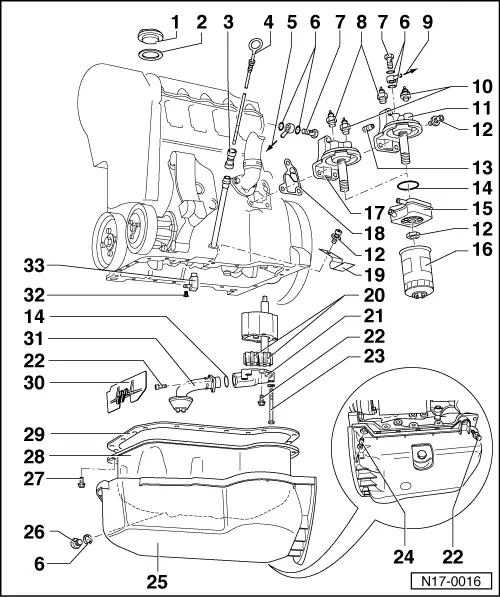

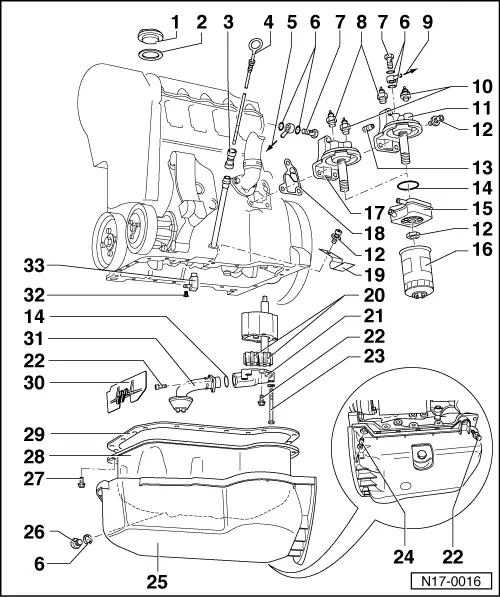

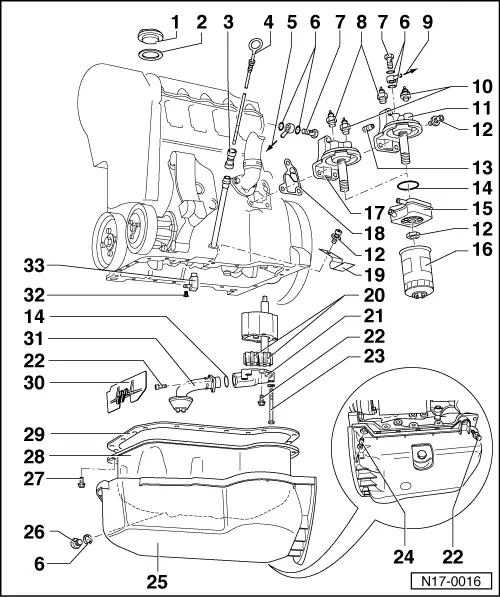

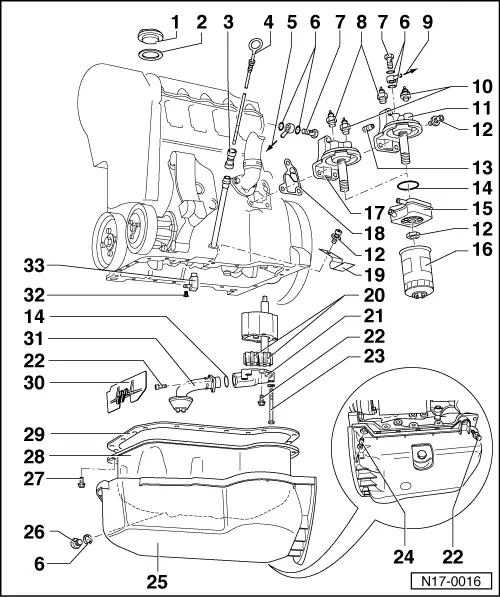

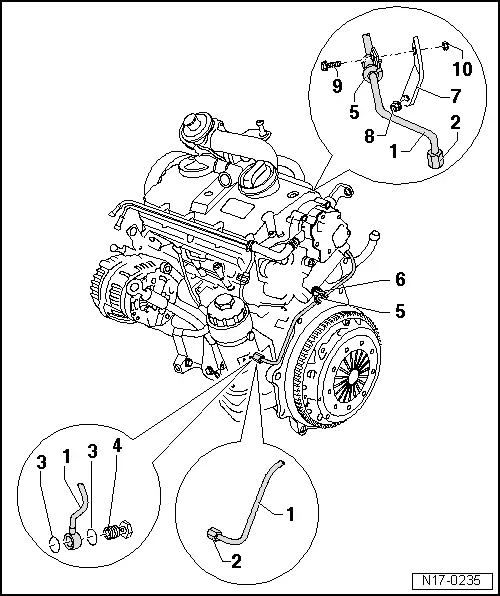

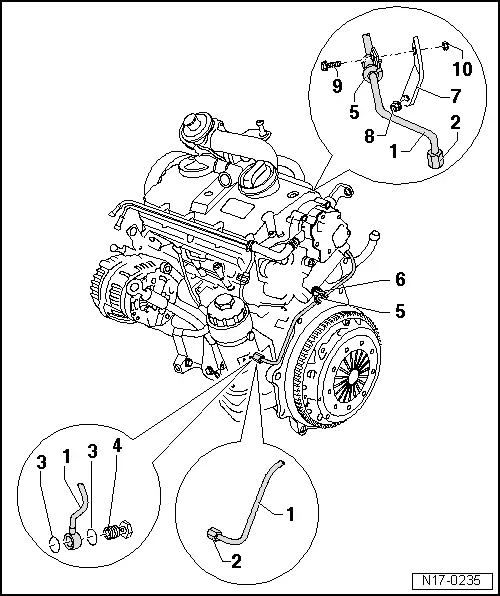

Removing and installing parts of the lubrication system

Removing and installing parts of the lubrication system

Notes:

-

◆ If large quantities of metal particles or other deposits (caused, for example, by partial seizure of the crankshaft or conrod bearings) are found in the engine oil when performing repairs, clean the oil passages thoroughly and renew the oil cooler in order to prevent further damage from occurring later.

-

◆ The oil level must not be above the max. mark - danger of damage to catalyst!

Checking oil pressure

Oil system capacity1):

without oil filter 3.8 ltrs.

with oil filter 4.3 ltrs.

1) Up-to-date figures:

=> Exhaust emissions test binder

Engine oil specifications:

Only use engine oil conforming to VW standard 50500.

|