Leon Mk1

|

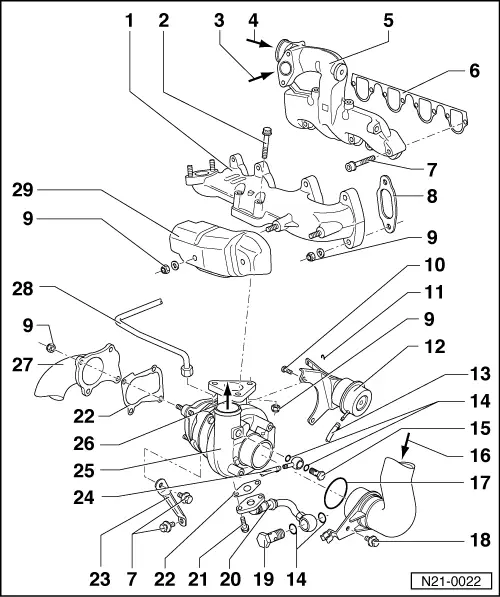

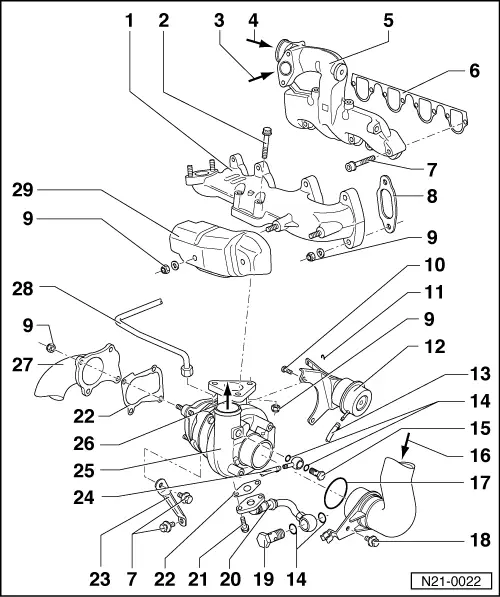

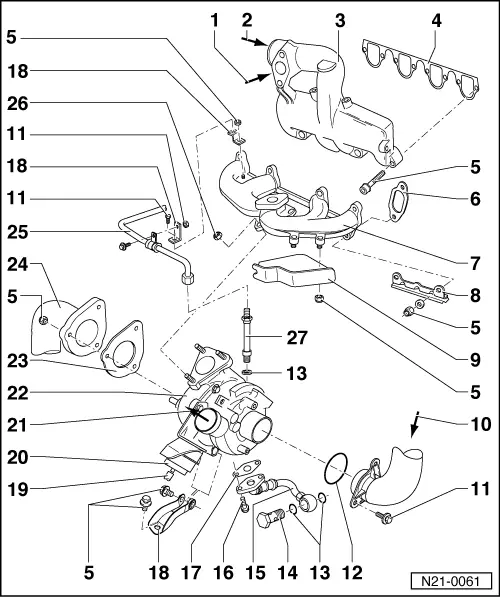

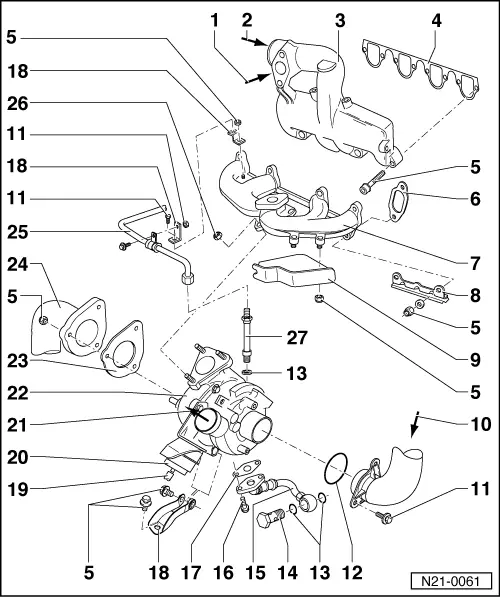

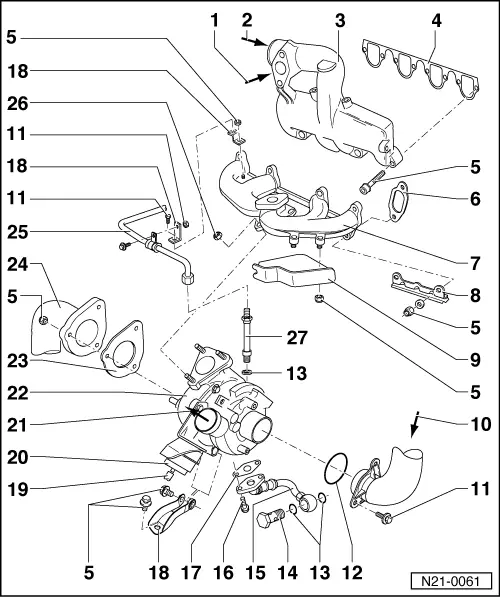

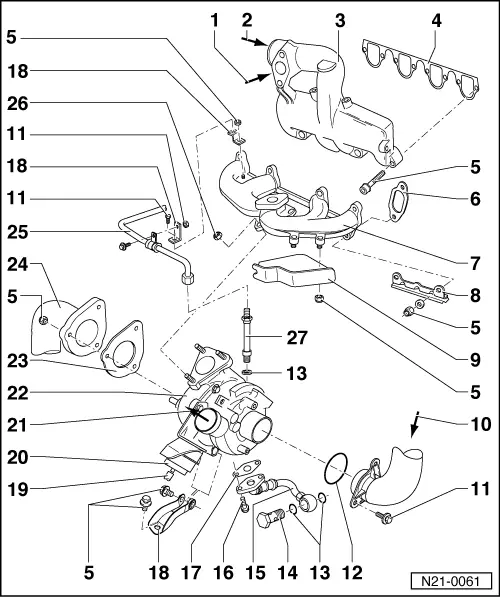

Charge air system with turbocharger

Removing and installing turbocharger with attachments

Observe safety precautions. Observe rules for cleanliness => Page 21-2. Notes: |

|

|

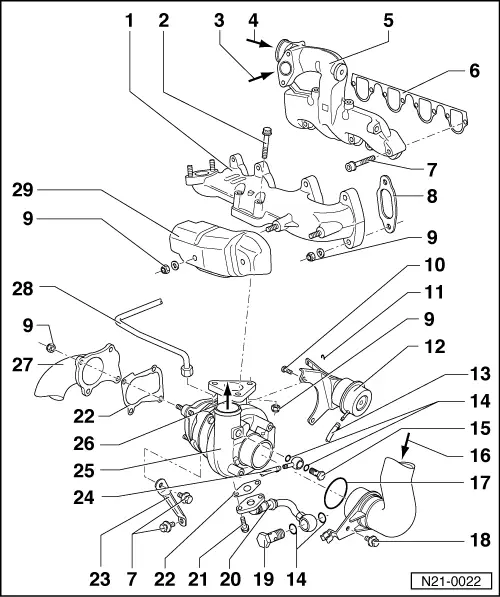

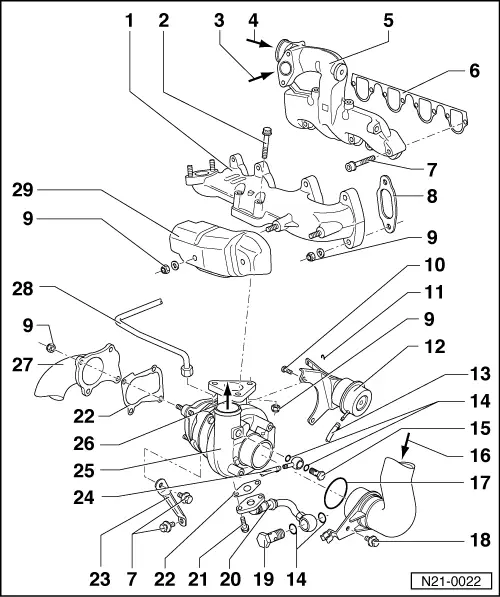

Engine codes 1Z, AHU Engine codes AFN, AVG Turbocharger hose connections, engine codes 1Z, AHU => Page 21-15 Turbocharger hose connections, engine codes AFN, AVG => Page 21-16 |

|

|

|

Engine codes 1Z, AHU |

|

|

|

|

|

|

|

|

|

|

Engine codes AFN, AVG

|

|

|

|

|

|

=> Repair group 23; Servicing diesel direct injection system; Checking charge pressure system

|

|

|

|