Leon Mk1

|

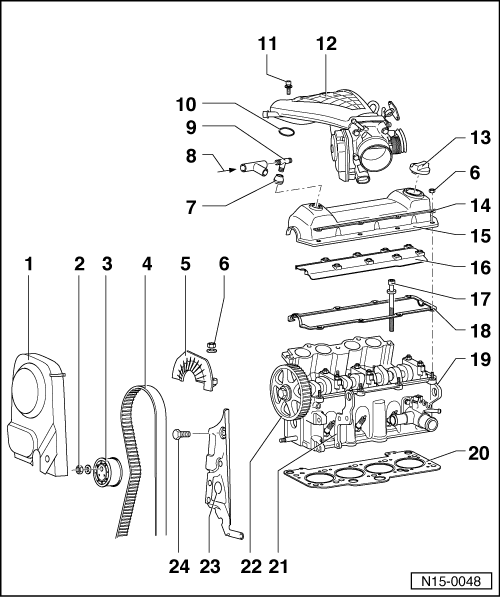

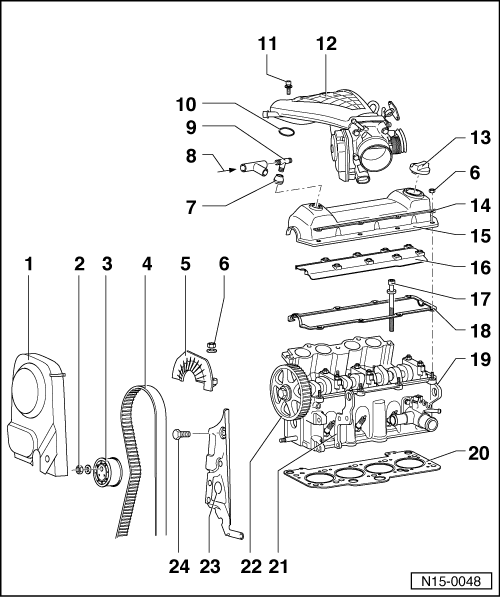

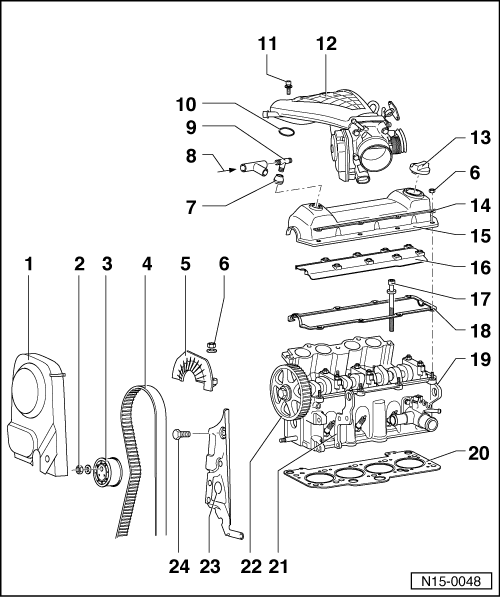

Removing and installing cylinder head

Removing and installing cylinder head

|

|

|

|

|

|

|

|

|

|

|

|

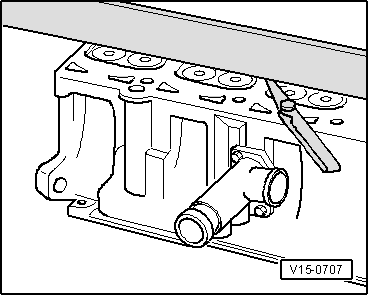

→ Fig. 1 Checking cylinder head for distortion Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Max. permissible distortion: 0.1 mm |