|

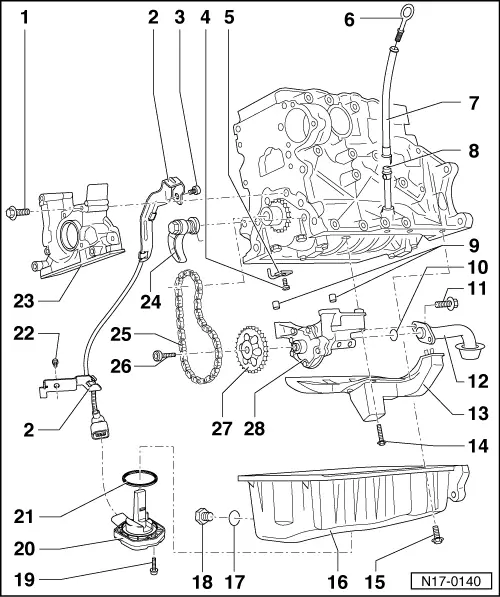

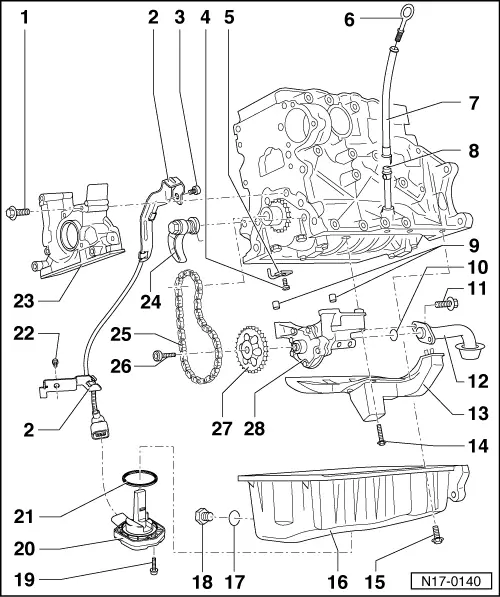

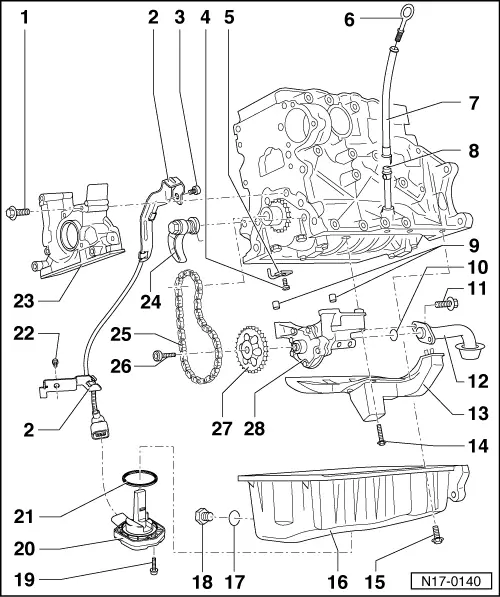

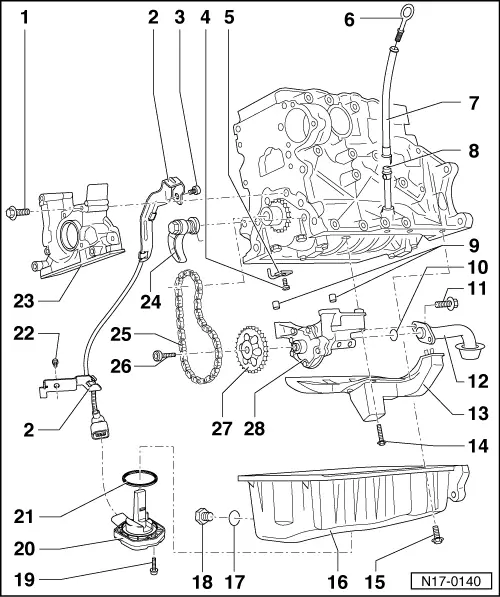

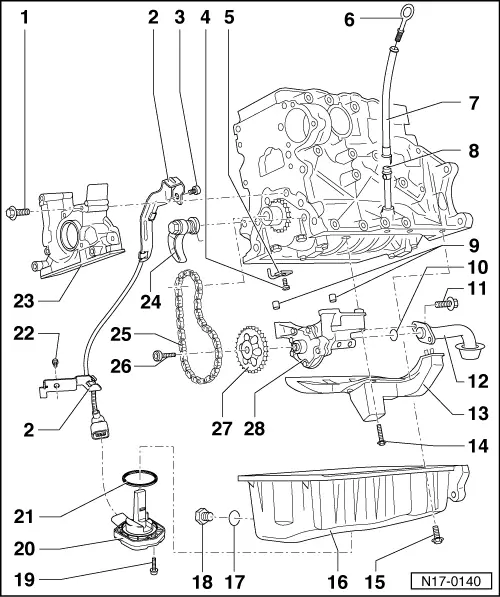

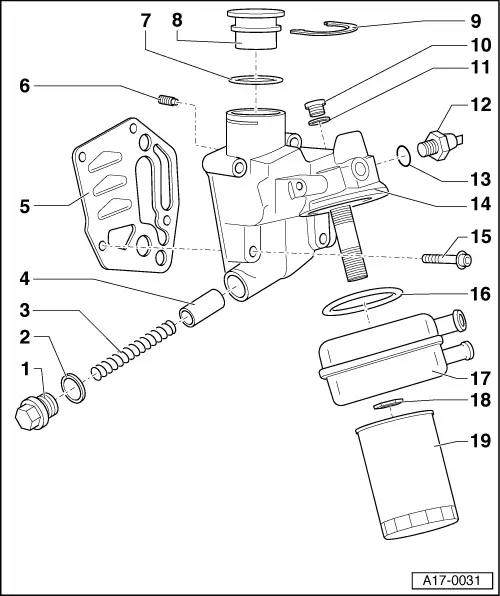

Removing and installing parts of the lubrication system

Removing and installing parts of the lubrication system

Notes:

-

◆ If when repairing an engine, metal shavings or a large quantity of small metal particles are found, this could indicate that the crankshaft and conrod bearings are damaged. To prevent consequential damage perform the following repairs:

-

‒ Thoroughly clean oil passages

-

‒ Replace oil spray jets

-

‒ Replace oil cooler

-

‒ Replace oil filter

-

◆ The oil level must not be above the max. mark - danger of damage to catalyst!

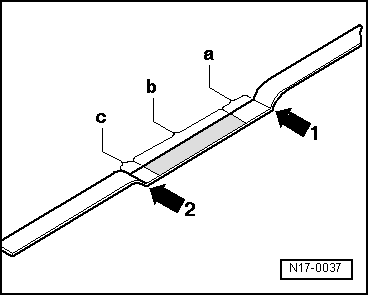

Marking , Fig.1

Checking oil pressure => Page 17-16

Oil system capacity1):

with oil filter 4.0 ltr.

1) Up-to-date figures:

=> Exhaust emissions test binder

Engine oil specificationswith long-life service

Use engine oils conforming to VW standard 503 00.

Notes:

-

◆ Engines are filled at the factory with oil conforming to VW standard 503 00. This engine oil is designed for long service intervals.

-

◆ Engine oils conforming to VW standard 500 00, 501 01 or 502 00 can be used furthermore. The oil must then be changed every 12 months or every 15,000 km and the service interval display must be programmed correspondingly. Procedure:

=> Maintenance manual

|