|

Removing and installing parts of the lubrication system

Removing and installing sump

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

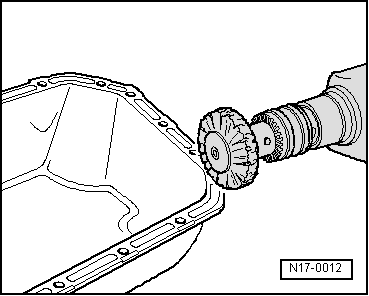

◆ Hand drill with plastic brush

-

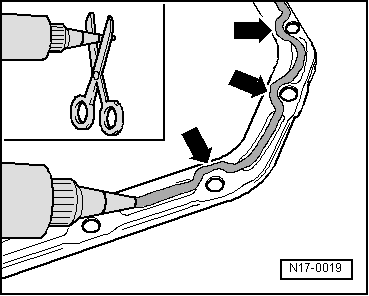

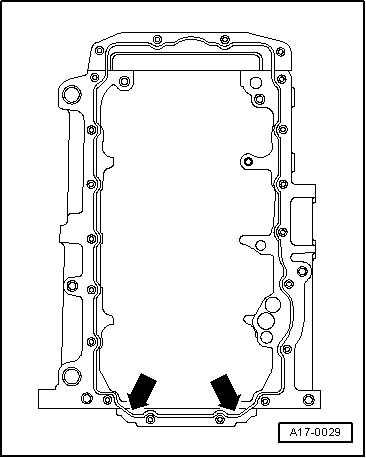

◆ Silicone sealant D176404 A2

-

◆ Protective glasses

-

◆ Flat scraper

Removing

-

‒ Remove noise insulation tray.

-

‒ Drain engine oil.

Note:

Observe disposal regulations!

-

‒ Pull 3-pin connector off oil level/temperature sender (G266).

-

‒ Remove sump, it may be necessary to release sump by tapping lightly with a rubber head hammer.

-

‒ Remove sealant residue on cylinder block with a flat scraper.

|