Leon Mk1

|

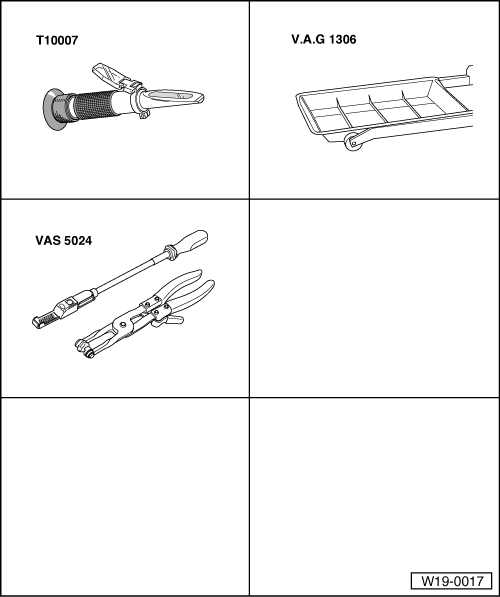

Removing and installing parts of cooling system

Draining and filling cooling system

|

|

|

|

|

|

Note: Observe disposal regulations! Filling Notes:

|

|

|||||||||||||||||||||

Recommended mixture ratios:

|

|

|

|

1) The amount of anti-freeze must not exceed 60 %; frost protection and cooling effect will decrease if amount of anti-freeze is too high. 2) The quantity of coolant can vary depending upon the vehicle equipment.

|

|

|

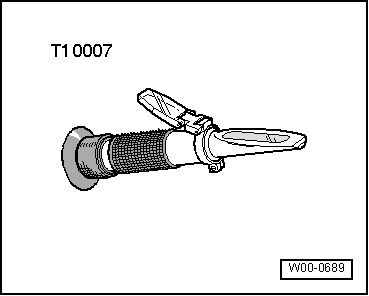

With cooling system charging unit VAS 6096

=> Operating instructions for cooling system charging unit VAS 6096 Not using cooling system charging unit VAS 6096

|

|

|

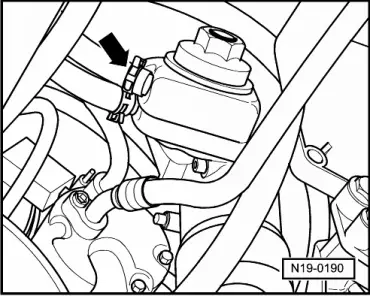

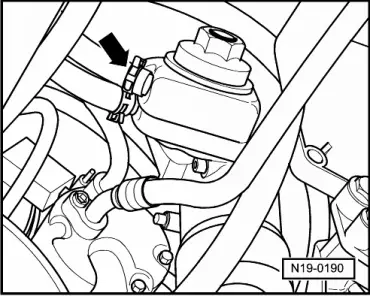

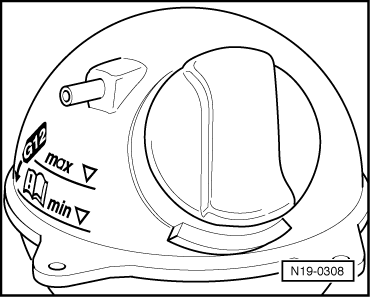

Warning !

Steam can be released when removing the cap from the expansion tank. Cover cap with a cloth and open carefully.

|