Leon Mk1

|

Removing and installing cylinder head

Adjusting valve timing

|

|

|

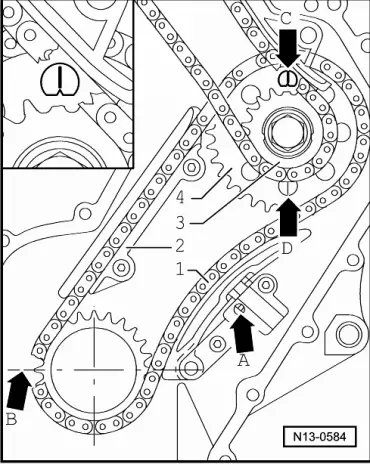

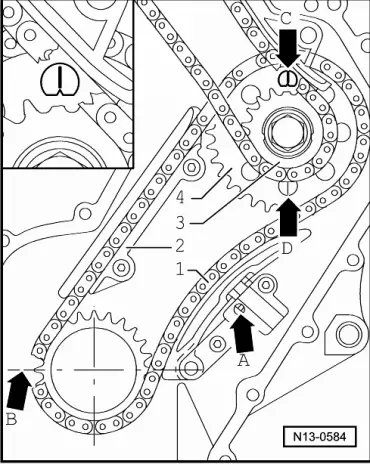

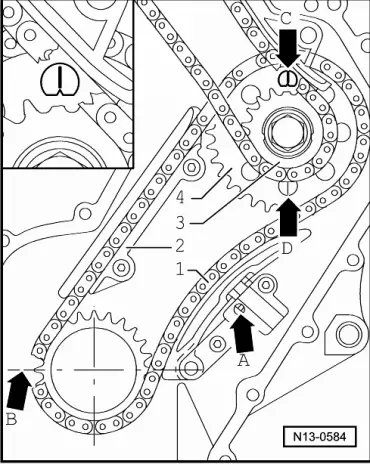

Note: Observe direction of rotation marks on used roller chain =>Page13-9, Fig.1

Take note when installing that the roller chain runs completely straight in the guide plate from the crankshaft to intermediate shaft. |

|

|

Note: Take note that all chain sprocket securing screws/bolts must be renewed.

|

|

|

|

|

|

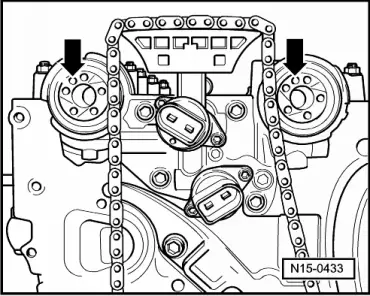

Install camshaft driver roller chain:

|

|

|

|

Note:

|

|

|

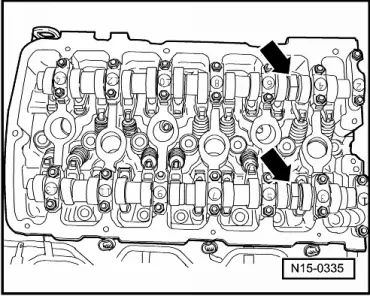

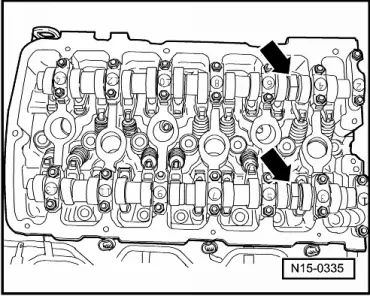

Note: If the cylinder head is removed:

|

|

|

|

|

|

|

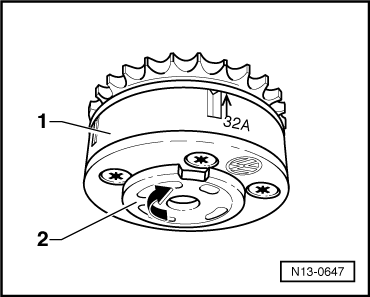

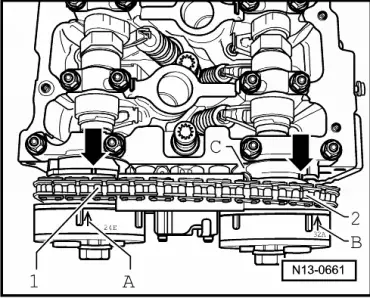

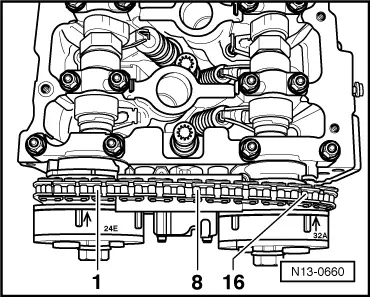

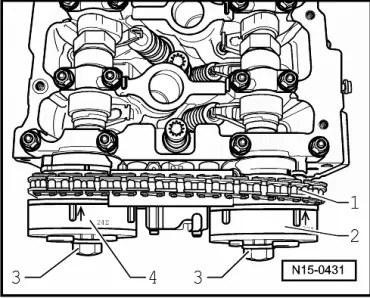

Note: → The exhaust camshaft adjuster -1- can be turned in two directions. When installing it, make sure that the sender wheel -2- of the Hall sender (G163) is turned to stop in direction of -arrow-. The distance between the two ground-down teeth of the inlet and exhaust camshaft adjusters must be exactly 16 rollers of the camshaft roller chain.

|

|

|

Note: |

|

|

|

The distance between the two ground-down teeth of camshaft adjuster sprocket must be 16 rollers.

Note: When the crankshaft is turned, the tensioner plate must be pressed against the camshaft roller chain by hand instead of with chain tensioner. If marks do not align:

|

|

|

|

If marks do not agree:

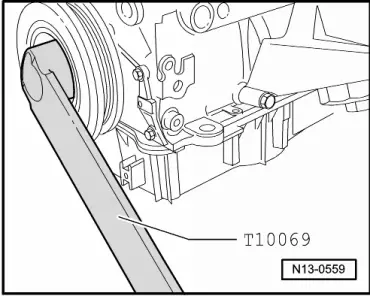

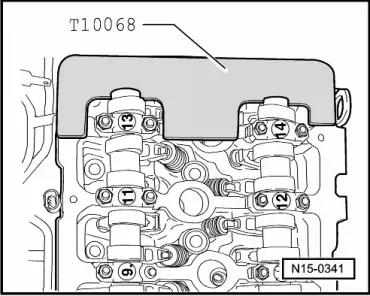

Note: The camshaft bar T10068 must be removed while this is done. |

|

|

|