Leon Mk1

|

Dismantling and assembling engine

Removing and installing ribbed belt

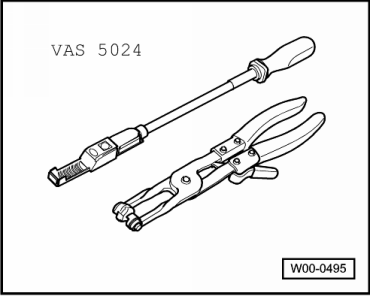

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required |

|

|

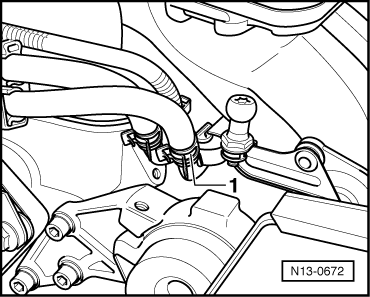

Removing ribbed belt Note: Before removing the ribbed belt mark the direction of rotation. When installing the belt ensure it is correctly seated in the pulley.

|

|

|

|

|

|

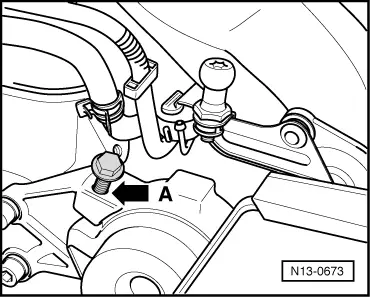

Note: Screw bolt in only until the ribbed belt can be removed. Otherwise the tensioner housing can be damaged.

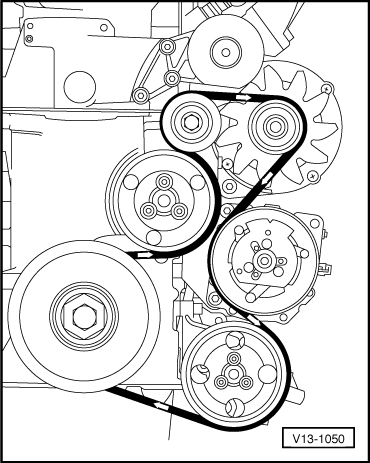

Installing ribbed belt

Notes:

|

|

|

After completing repairs always:

|