Leon Mk1

|

|

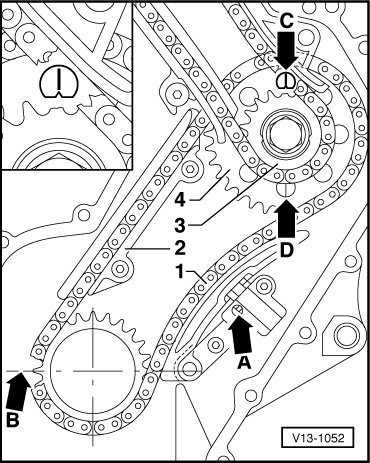

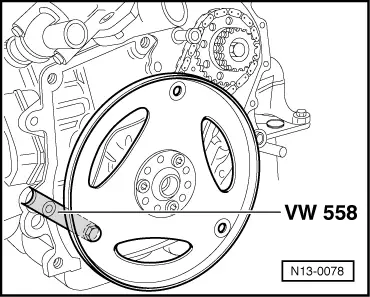

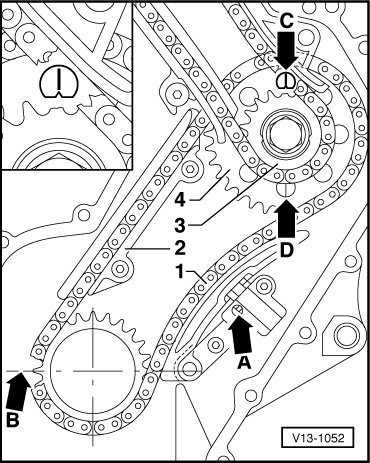

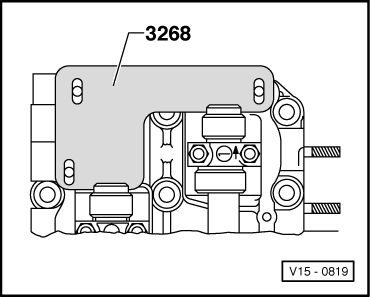

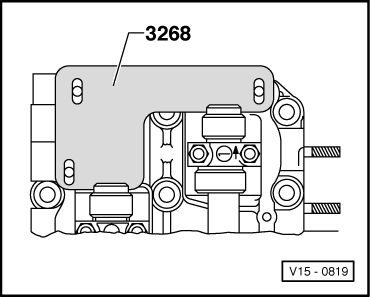

Work sequence Engine removed Install single chain and chain tensioner with tensioning plate: |

|

|

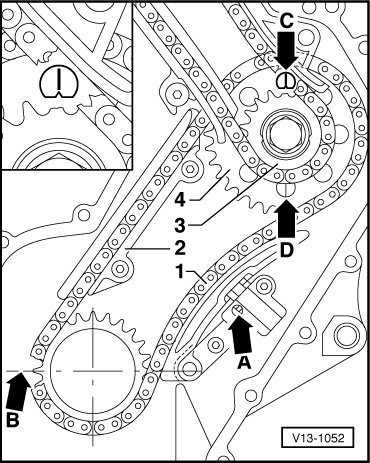

Vehicles with manual gearbox

Vehicles with automatic gearbox

|

|

|

Continuation for all vehicles |

|

|

Install double chain and chain tensioner with tensioning plate: |

|

|

Note: With cylinder head removed:

Notes:

|

|

|

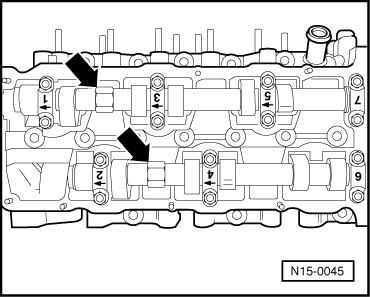

→ Note: Only counter-hold with 24 mm open jaw spanner on the camshaft -arrow-. The camshaft jig must not be fitted when tightening/loosening the sprockets.

Notes:

|

|

|

Engine installed, cylinder head removed

|

|

|

|

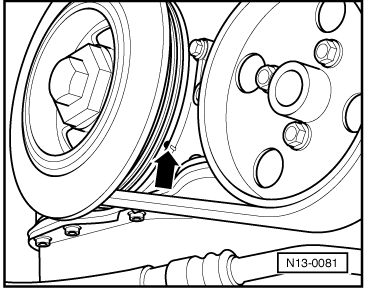

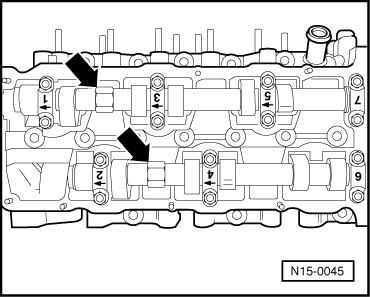

→ If the TDC No. 1 Cyl. setting is correct it is possible to see a notch on the intermediate shaft sprockets -arrow-. If the notch cannot be seen:

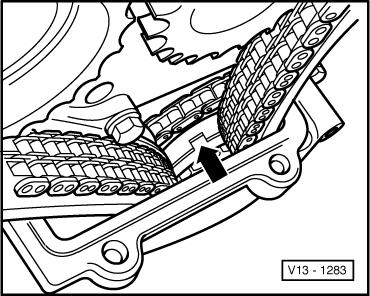

Note: If the crankshaft is turned with the cylinder head removed, a 2nd mechanic should guide the double chain by hand to prevent it jamming. |

|

|

Notes:

|

|

|

|

→ Note: Only counter-hold with 24 mm open jaw spanner on the camshaft -arrow-. The camshaft jig must not be fitted when tightening/loosening the sprockets.

Notes:

|