Leon Mk1

|

|

Notes:

Work sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

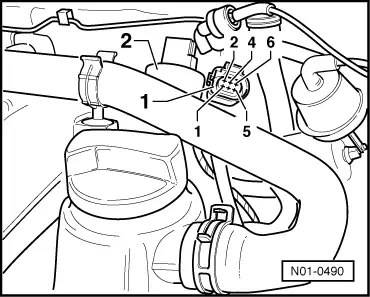

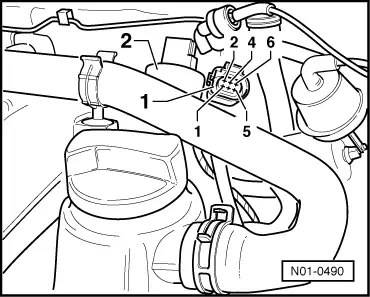

Activating activated charcoal filter solenoid valve 1 (N80):

|

| → Indicated on display: |

|

||

If the solenoid valve does not click: |

|

|

LED flashes:

|

| → Indicated on display: |

|

||

LED does not flash:

|

| → Indicated on display: |

|

||

|

|

|

|

|

|

If no fault is detected in the wiring:

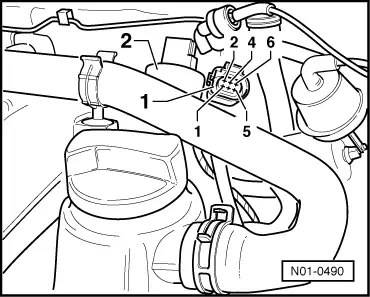

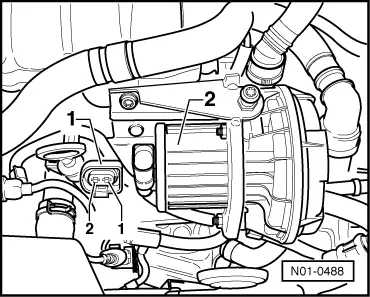

Activate exhaust gas recirculation valve (N18):

|

| → Indicated on display: |

|

||

|

|

|

|

If the exhaust gas recirculation valve does not click:

LED flashes:

|

| → Indicated on display: |

|

||

=> Rep.-Gr. 26; Exhaust gas recirculation system

LED does not flash:

|

| → Indicated on display: |

|

||

|

|

|

If the specification is not attained: |

|

|

=> Current flow diagrams, Electrical fault finding and Fitting locations binder If the specification is obtained:

|

|

|

|

|

|

If no fault is detected in the wiring:

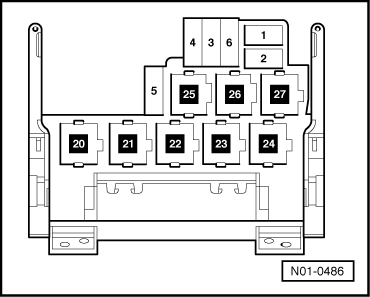

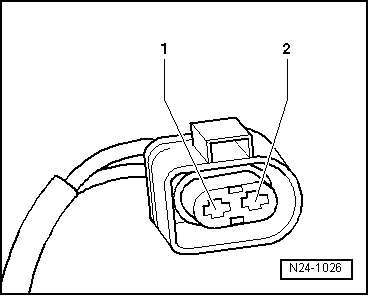

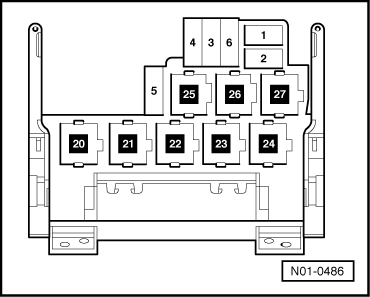

Activating secondary air pump relay (J299):

|

| → Indicated on display: |

|

||

If the secondary air pump motor (V101) does not run at intervals: |

|

|

LED flashes:

|

| → Indicated on display: |

|

||

=> Repair group 26; Secondary air system; Removing and installing parts of secondary air system If the LED does not flash but the secondary air pump relay clicks:

|

| → Indicated on display: |

|

||

|

|

|

If no wiring fault is detected: |

|

|

=> Current flow diagrams, Electrical fault finding and Fitting locations binder |

|

|

Notes:

|

|

|

If no wiring fault is detected:

If voltage supply is OK:

If the LED does not flash and the secondary air pump relay does not click:

|

| → Indicated on display: |

|

||

|

|

|

Notes:

|

|

|

LED flashes:

|

| → Indicated on display: |

|

||

LED does not flash: |

|

|

LED does not light-up:

LED lights up:

|

| → Indicated on display: |

|

||

|

|

|

If no wiring fault is detected:

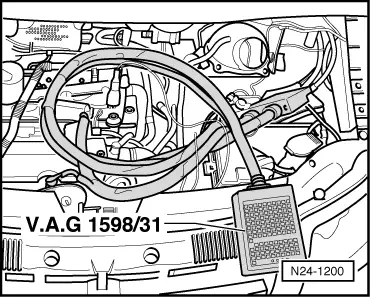

Activate injectors (N30...N33):

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

Note: The fuel pump must run and the flow noise must be distinctly audible at the fuel pressure regulator. If the fuel pump does not run, check activation. => Repair group 20; Removing and installing parts of the fuel system; Checking fuel pump

If one of the injectors is not activated (does not click):

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|