|

Servicing ignition system

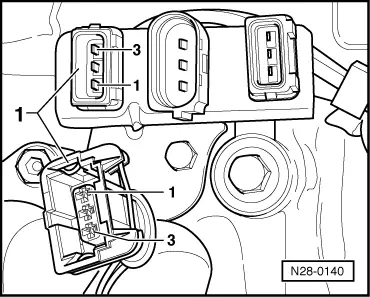

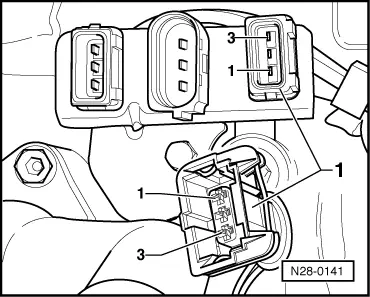

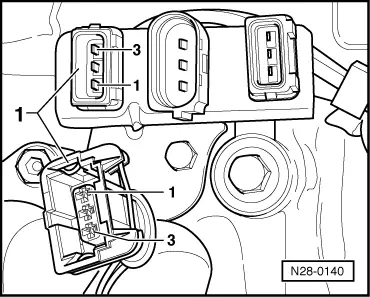

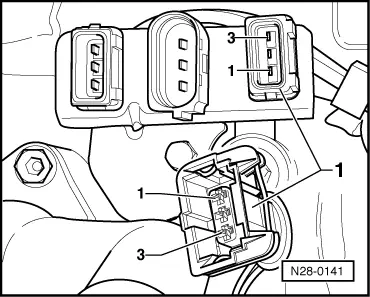

Checking knock sensor

Notes:

-

◆ It is extremely important to keep to the tightening torque of 20 Nm to ensure the knock sensors perform perfectly.

-

◆ Only gold-plated contacts may be used when servicing the knock sensor connector contacts.

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

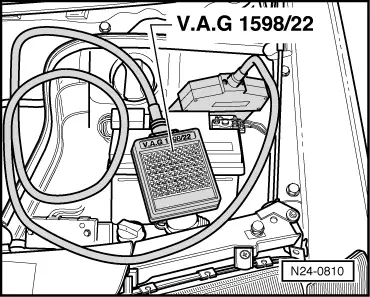

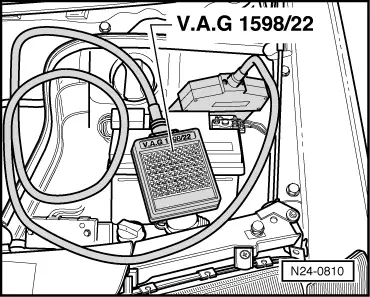

◆ Test box V.A.G 1598/22

-

◆ Hand multimeter V.A.G 1526 or multimeter V.A.G 1715

-

◆ Adapter set V.A.G 1594

-

◆ Current flow diagram

Test conditions

-

● Self-diagnosis must have recognized a fault on one or both knock sensors.

Checking function

-

‒ Functional check of knock control and knock sensors read measured value block, display groups 14 to 16 and 24.

Checking resistances and wiring

|