|

Servicing ignition system

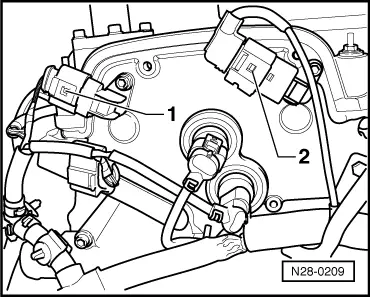

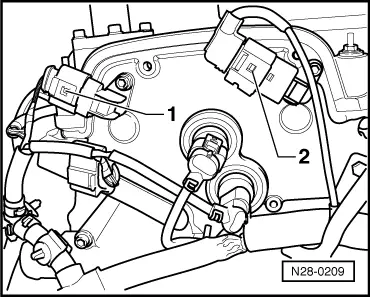

Checking Hall sender

Notes:

-

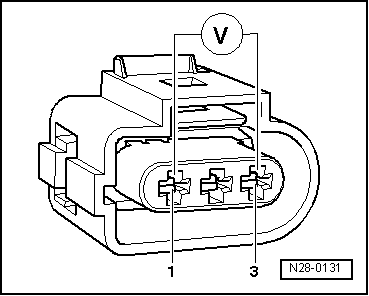

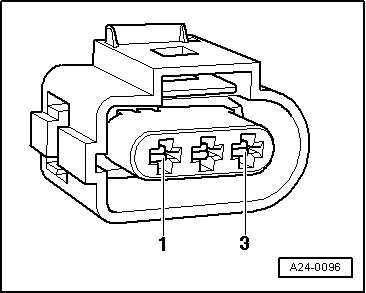

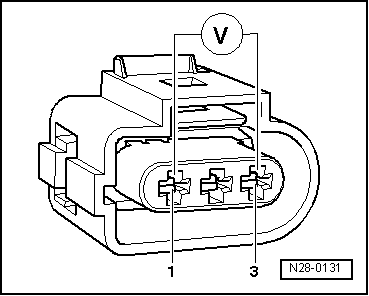

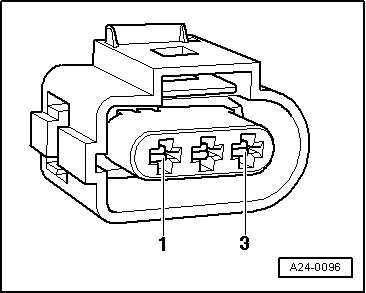

◆ Always mark connectors before pulling off (danger of interchanging).

-

◆ Only gold plated connectors may be used to service contacts in connectors for Hall senders.

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

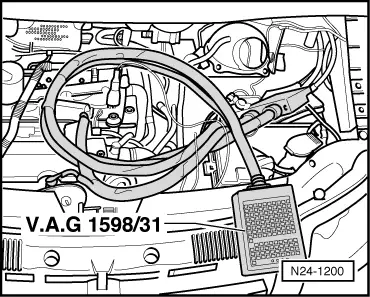

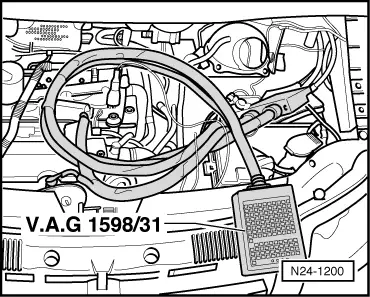

◆ Test box V.A.G 1598/31

-

◆ Hand multimeter V.A.G 1526 or multimeter V.A.G 1715

-

◆ Adapter set V.A.G 1594

-

◆ Current flow diagram

Check conditions

-

● Hall sender screwed on tight

-

● The battery voltage must be at least 11.5 V.

|