Leon Mk1

|

|

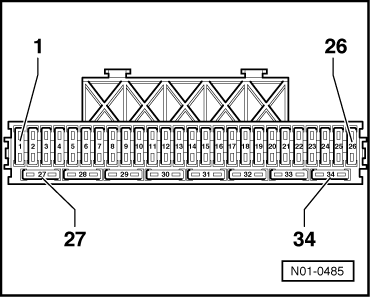

Note: Removing fuse No. 14 interrupts the voltage supply to the injectors and fuel pump.

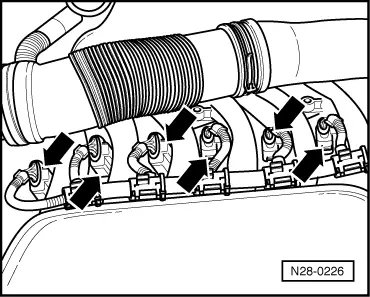

Note: Ignition coils and output stages are single components and cannot be renewed separately. |

|

|

|

Test sequence

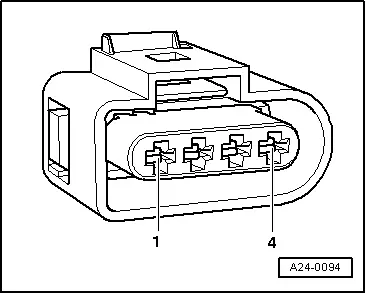

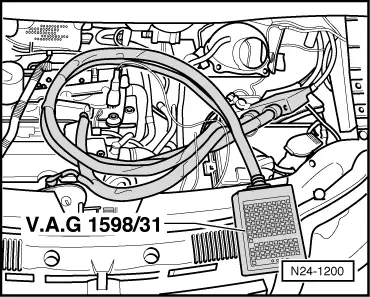

Checking voltage supply |

|

|

If no voltage is present: |

|

|

When the LED flickers and the supply voltage is OK.:

The LED does not flicker: Checking wiring

|

|

|

|

|

|

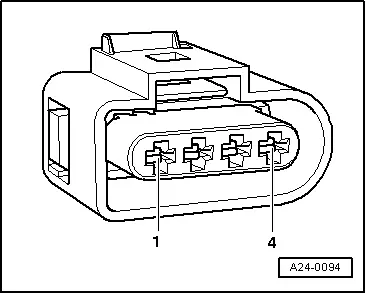

If no wiring fault is detected and voltage was present between contacts 1+3 and 2+3.

|