Leon Mk1

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: (1...4 = Display zones) |

|

||||||||||||||||||||||||||||||||||||||||

|

Note: Checking the knock sensors must be performed during a test drive because the diagnosis of the knock sensors is not activated until the engine speed exceeds 2000 rpm and the engine is loaded by more than 40 %.

Observe the valid safety precautions when carrying out a test drive => Page 28-8.

If the specification is attained:

Continuation: If the specifications are not obtained:

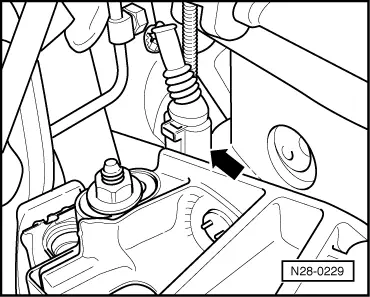

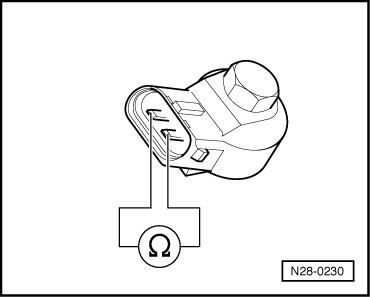

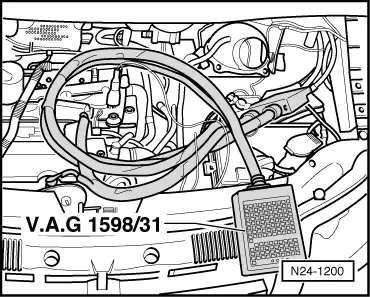

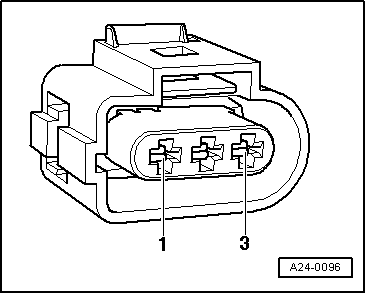

Checking resistance of knock sensors Knock sensor 1 (G61) | |||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

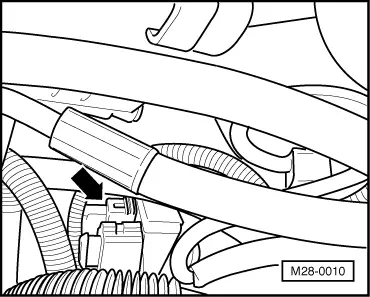

Knock sensor 2 (G66) |

|

|

|

|

|

If the specification is not obtained:

If the specification is obtained: Checking wiring

|

|

|

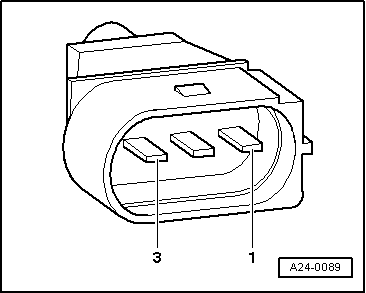

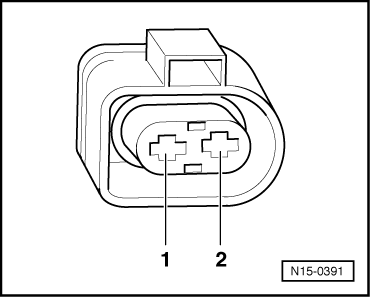

Knock sensor 1 (G61) |

|

|

Knock sensor 2 (G66) |

|

|

If no wiring fault is detected:

If the fault is still present: |