| t

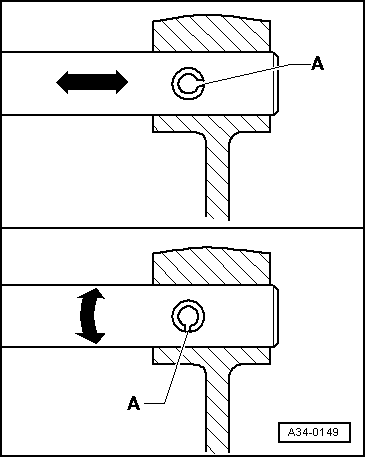

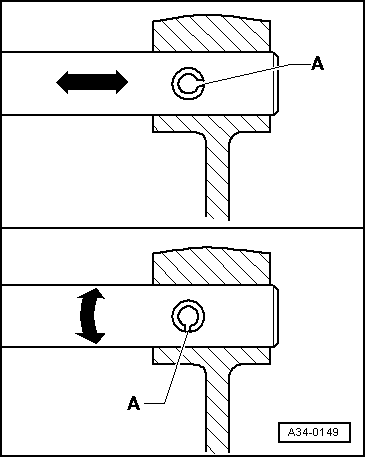

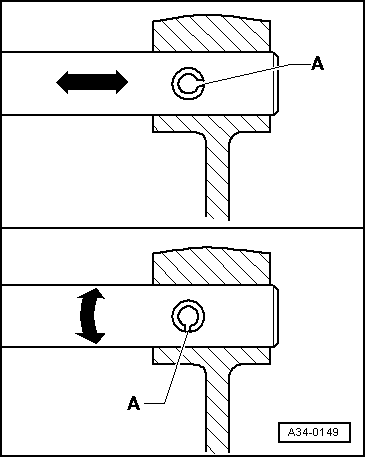

| Replace the support sleeves. Installation position: the groove-A- must remain parallel to the direction of the flow of pressure -arrow-. |

| t

| Loosen and tighten nuts and bolts on covers and casings in diagonal sequence. |

| t

| Do not bend the parts, especially fragile parts; loosen and tighten them in stages in diagonal sequence. |

| t

| The torque settings refer to non-lubricated nuts and bolts. |

| t

| Always replace any self-locking nuts and bolts. |

| t

| Contact surfaces, bolts and nuts for all threaded joints must be waxed when fitted if necessary. |

| t

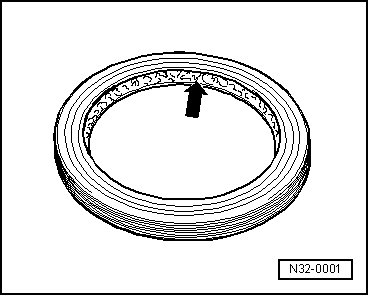

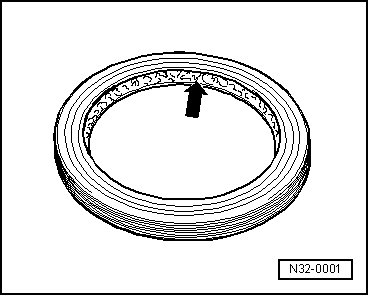

| The needle bearings must be inserted with the engraved part (thicker side of the plate) facing towards the installation tool. |

| t

| All bearings of the gearbox must be fitted lubricated with sprocket oil. |

| t

| Conical roller bearings fitted into one same shaft must be replaced together. If possible, use parts from the same manufacturer. |

| t

| Before fitting interior rings, heat them to approx. 100 °C. |

| t

| Do not confuse the outside and inside rings of the bearing with the rings from other bearings of the same size. The bearings come in matched pairs. |

| t

| Check shim settings at various points, using a micrometer. The existence of different tolerances allows the exact calibration of the thickness of the shim needed. |

| t

| Check they have no lips and that they are not damaged. |

| t

| Only fit shims in perfect condition. |

|

|

|