| t

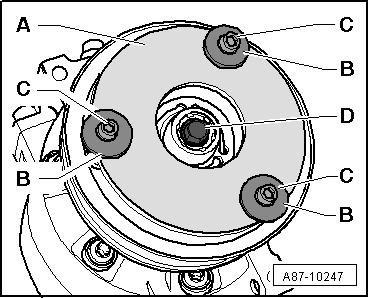

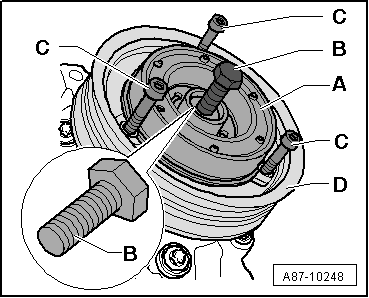

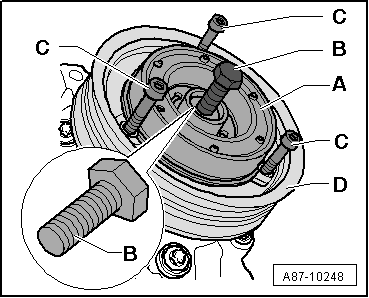

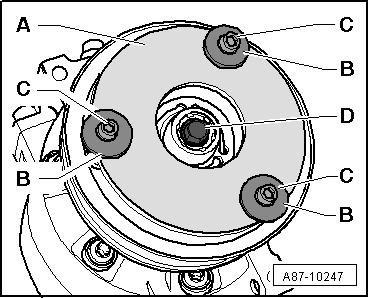

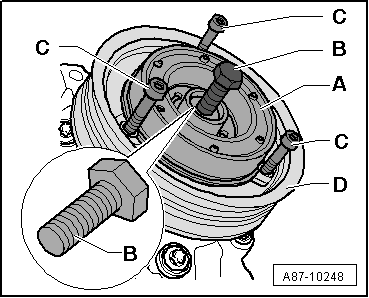

| If the drive plate -A- is fastened to the compressor shaft, fit three long bolts -C- through the orifices in the clutch plate -A- on the pulley -D- and separate the drive plate -A- with a normal bolt -B- (bolt with M8 thread, flat in front and with a resistance of min. 10.9). At the same time, hold the pulley -D- with a normal strap wrench (with a braided strap). |

| t

| When the drive plate -A- has already been replaced once and has been pasted with sealing agent D 154 102 A1, it may occur that the plate connects itself with the compressor shaft in such a way that it will not be able to be separated. In this case the complete compressor must be replaced. |

| –

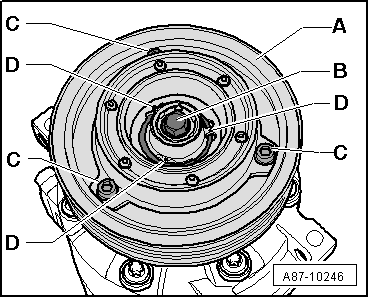

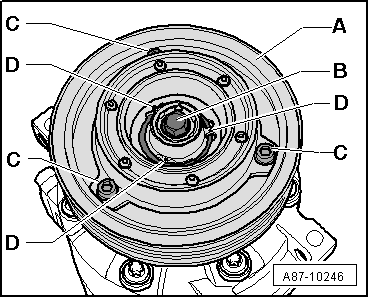

| If the pulley must be replaced, release the circlip and remove the pulley |

| –

| Clean the grooves of the compressor shaft and examine it; replace the compressor if there are signs of wear in the grooves |

Caution | Do not use compressed air for cleaning, as the dirt particles can reach the compressor shaft seal and damage it. |

|

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note