Leon Mk1

|

Servicing clutch

Servicing clutch

|

|

|

|

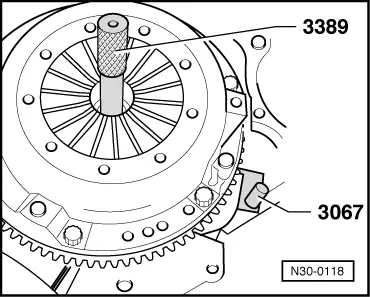

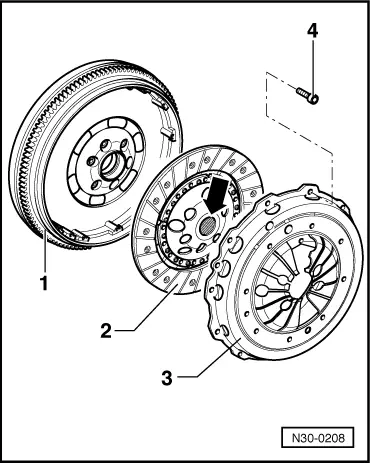

Modifications to clutch for vehicles with 1.8 ltr. - 110 kW engine and 1.9 ltr. - 81 kW turbo diesel engine =>Page 30-26 (Gearbox removed) Notes:

=> Repair group13 |

|

|

Note: Clean input shaft splines and on used clutch plates, the hub splines. Remove corrosion and apply only a very thin coating of grease Part No: G 000 100 to the input shaft splines. Then move clutch plate to and fro on input shaft until hub moves freely on shaft. Excess grease must be removed. |

|

|

|

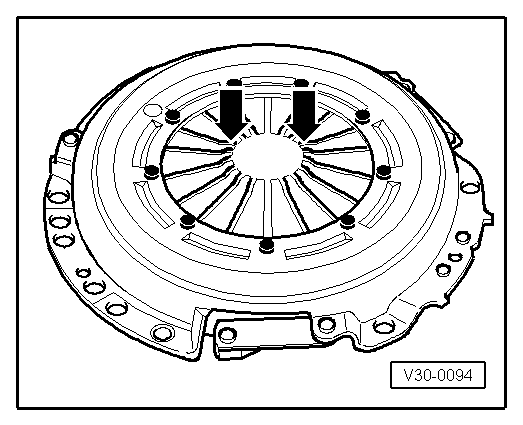

Note: Pressure plates are protected against corrosion and greased. Only the contact surface may be cleaned, otherwise the service life of the clutch will be considerably reduced.

|

|

|

|

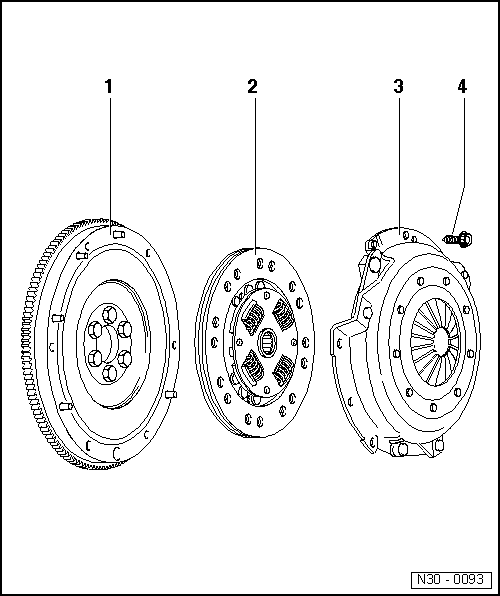

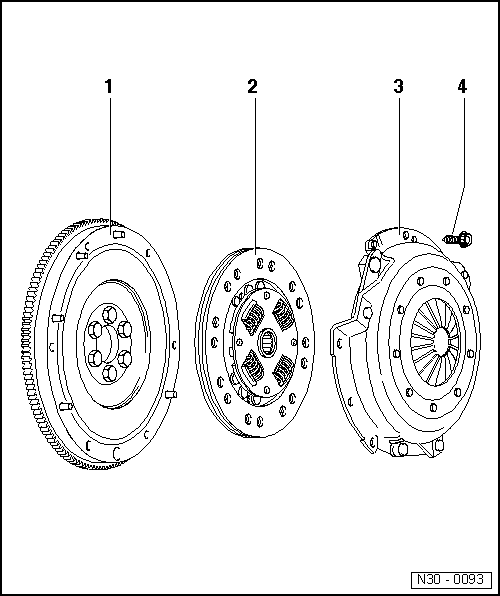

Clutch

Installation position: The shorter end of the hub (arrow) faces to pressure plate -3-.

Tightening torque Pressure plate multi point socket head bolts -4- to flywheel: 13 Nm.

|