Leon Mk1

|

Adjusting differential

Adjusting differential

The differential must be adjusted, when

|

|

|

or the

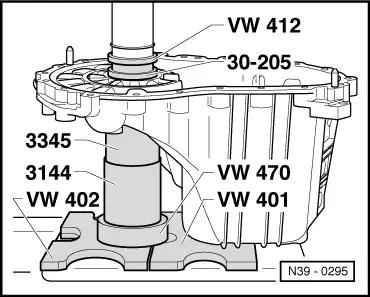

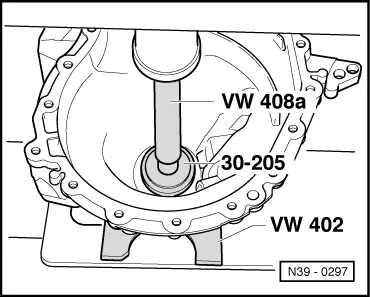

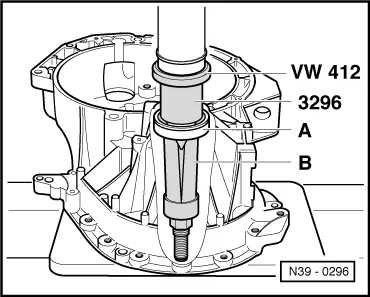

have been renewed. Adjustment overview .

|

|

|

|

Note: Taper roller bearing inner and outer races are paired. Do not interchange!

|

|

||||||||

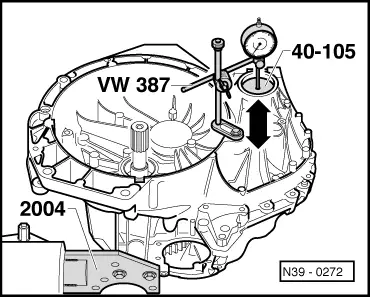

Note: This preparation is to be repeated for each subsequent measurement, otherwise the gauge will not return to the starting position.

Determining shim S2 thickness The specified bearing preload is obtained by adding the gauge reading Example:

|

|

|||||

Table of "shims":

1) To determine shim add gauge reading to measurement shim |