Leon Mk1

|

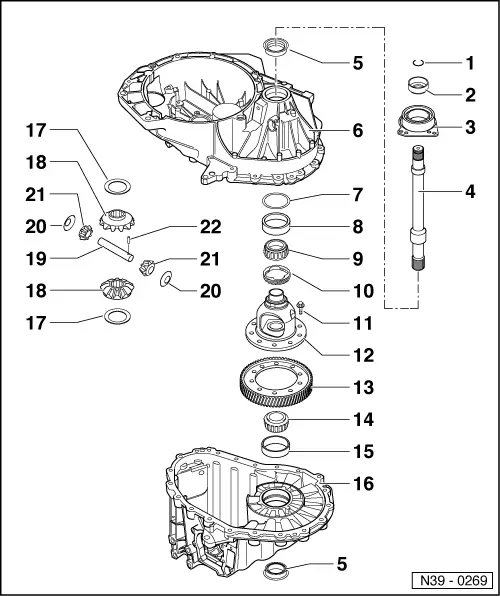

Dismantling and assembling differential

Dismantling and assembling differential

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

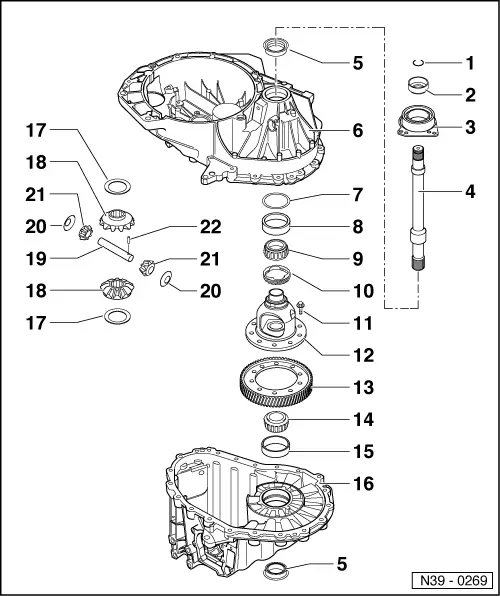

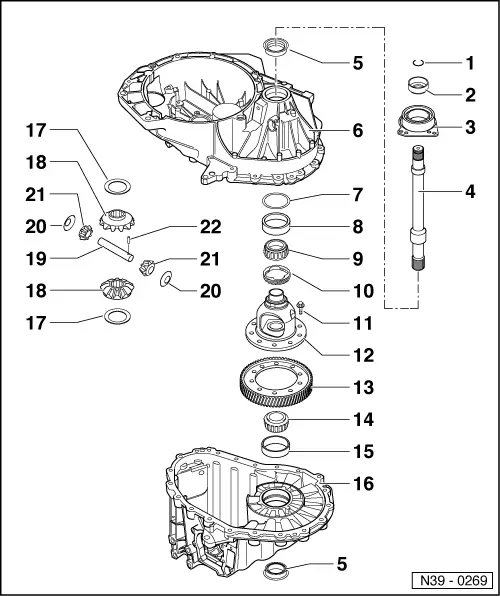

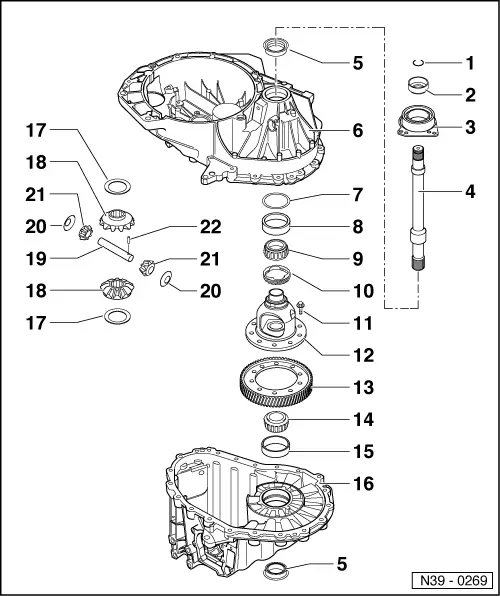

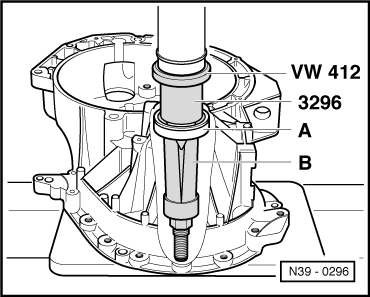

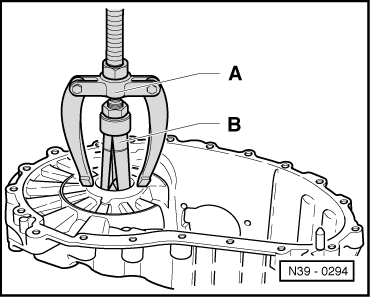

→ Fig.1 Pulling out oil seal. A - Counter support, e.g. Kukko 22/2 B - Internal puller 36...46 mm, e.g. Kukko 21/6 Note: Pulling the left and right-hand seals out is the same. |

|

|

|

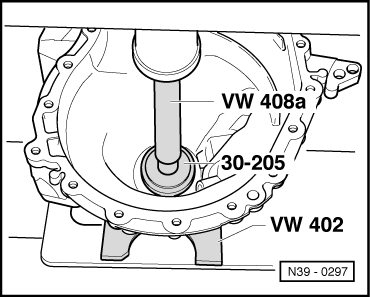

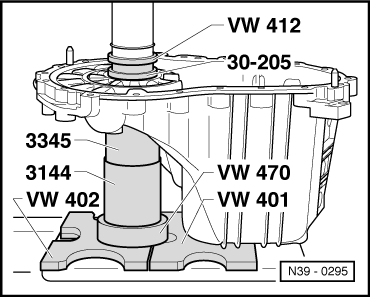

→ Fig.2 Driving in oil seal Note: Pressing the left and right-hand seals in is the same. |

|

|

|

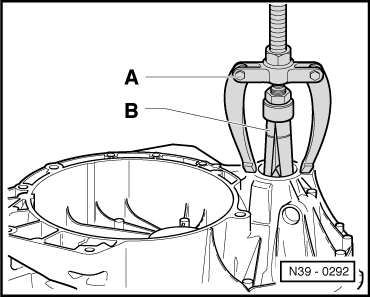

→ Fig.3 Pressing taper roller bearing outer race -A- out from clutch housing B - Internal puller 46...58 mm, e.g. Kukko 21/7 |

|

|

|

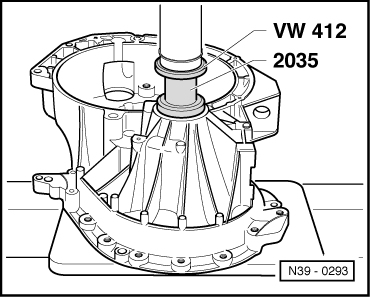

→ Fig.4 Pressing taper roller bearing outer race into clutch housing

|

|

|

|

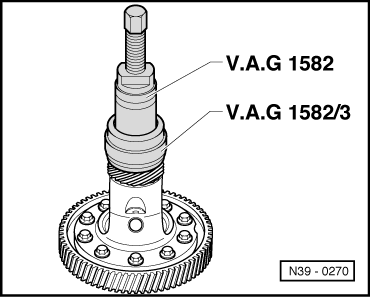

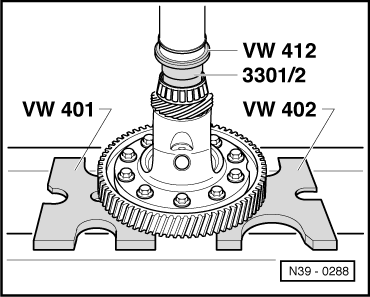

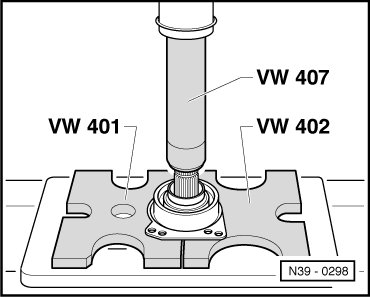

→ Fig.6 Pressing on taper roller bearing inner race Note: The taper roller bearing inner races for gearbox housing and clutch housing are pressed on with the same press tools. |

|

|

|

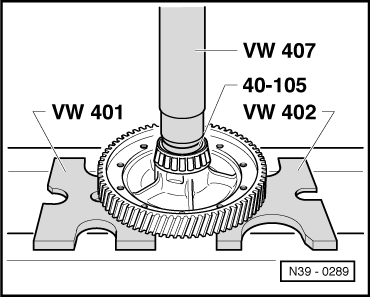

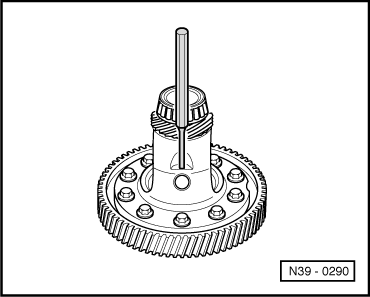

→ Fig.7 Pressing off final drive gear

|

|

|

|

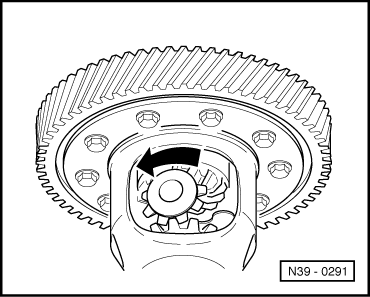

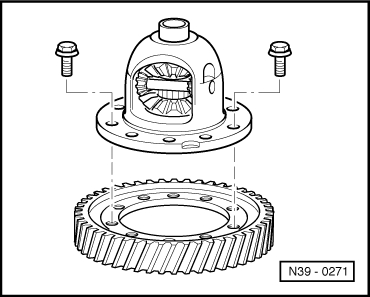

→ Fig.8 Bolting final drive gear and differential housing together Note: Tighten final drive gear wheel evenly and diagonally. |

|

|

|

→ Fig.9 Pulling taper roller bearing outer race out from gearbox housing A - Counter support, e.g. Kukko 22/2 B - Internal puller 46...58 mm, e.g. Kukko 21/7 |

|

|

|

→ Fig.10 Pressing taper roller bearing outer race into gearbox housing |

|

|

|

→ Fig.11 Removing and installing planet wheel axis shaft spring pin Removing

Installing |

|

|

|

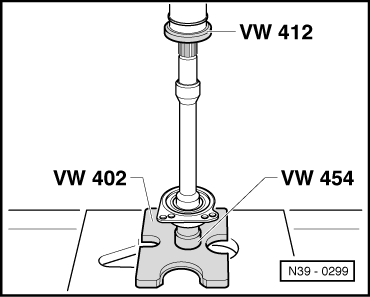

→ Fig.13 Pressing off centre bearing with protective cap |

|

|

|

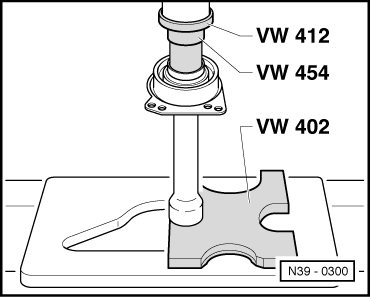

→ Fig.14 Pressing on centre bearing |

|

|

|

→ Fig.15 Pressing on protective cap |