-

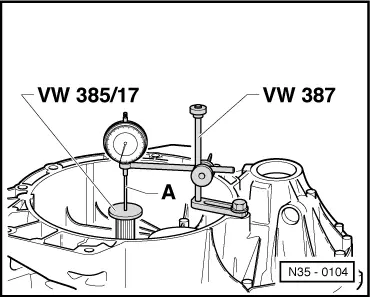

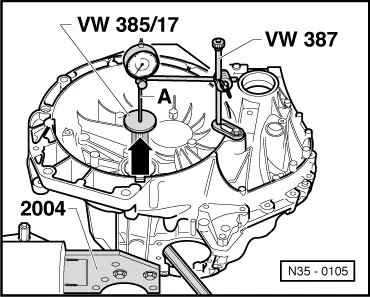

‒ → Press input shaft using an assembly lever, in direction of D.T.I.

-

‒ Read off and note clearance indicated on D.T.I. (example 0.23).

Note:

D.T.I. does not return to original position.

Determining thickness of shim

The specified bearing preload is obtained by adding the gauge reading

(0.23 mm) and the thickness of the measurement shim installed

(1.00 mm) to a constant, for preload

(0.06 mm).

Example:

|

Measurement shim installed

|

1.00 mm

|

|

+ Reading

|

0.23 mm

|

|

+ Preload (constant)

|

0.06 mm

|

|

Thickness of shim

|

1.29 mm

|

-

‒ Specify thickness of shim according to table => Page 35-18 and determine Part No. from parts catalogue.

Table of "shims":

|

|

|---|

|

Gauge reading (mm)

|

Shims (mm)

|

|

Measurement shim1)

0.20 - 0.21

0.22 - 0.23

0.24 - 0.25

0.26 - 0.27

0.28 - 0.29

0.30 - 0.31

0.32 - 0.33

0.34 - 0.35

0.36 - 0.37

0.38 - 0.39

0.40 - 0.41

0.42 - 0.43

0.44 - 0.45

0.46 - 0.47

0.48 - 0.49

0.50 - 0.51

0.52 - 0.53

0.54 - 0.55

0.56 - 0.57

0.58 - 0.59

0.60 - 0.61

0.62 - 0.63

0.64 - 0.65

|

1.00

1.27

1.29

1.31

1.33

1.35

1.37

1.39

1.41

1.43

1.45

1.47

1.49

1.51

1.53

1.55

1.57

1.59

1.61

1.63

1.65

1.67

1.69

1.71

|

1) To determine shim add gauge reading to measurement shim

|