Leon Mk1

|

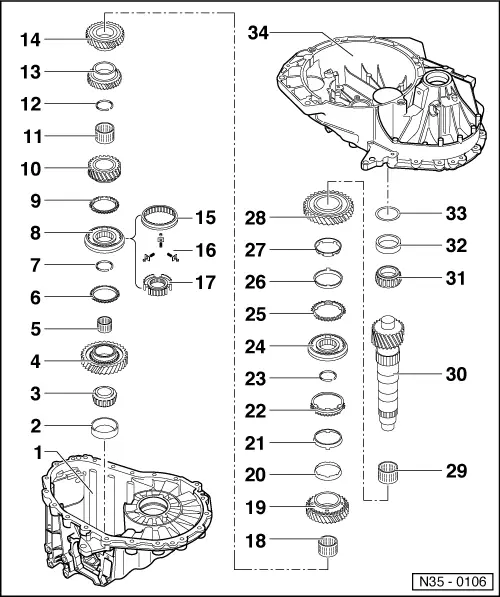

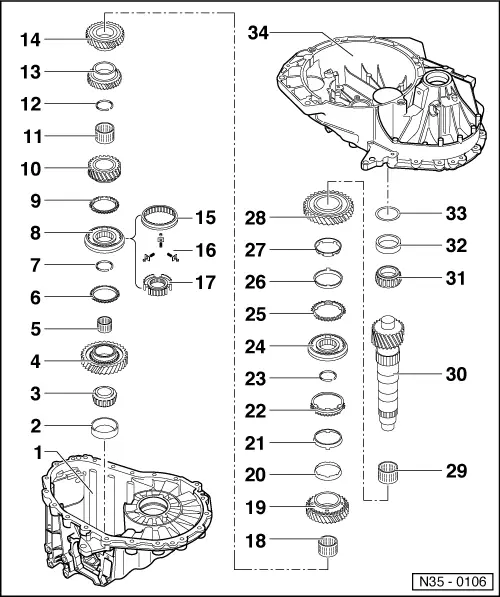

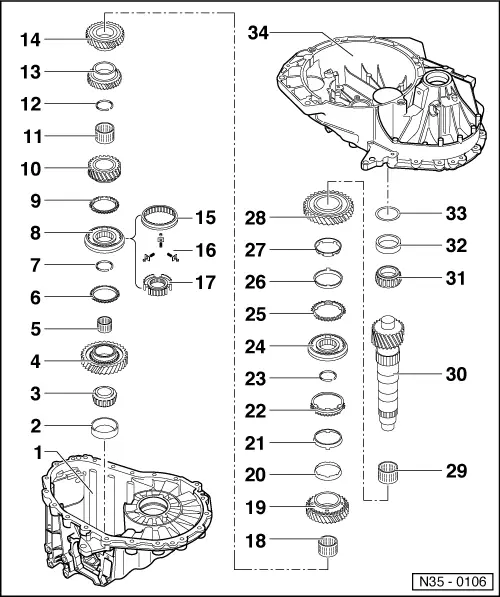

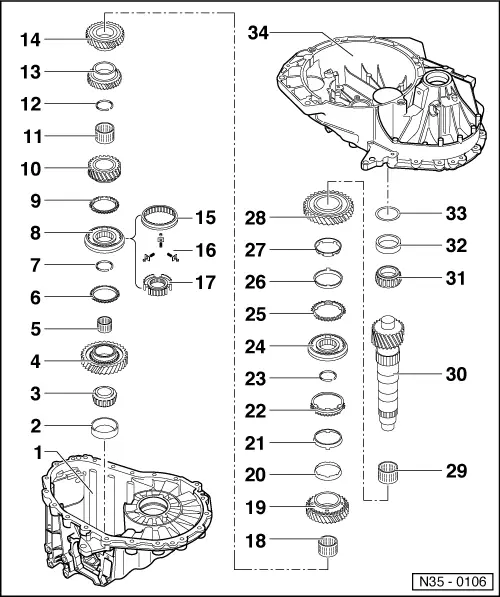

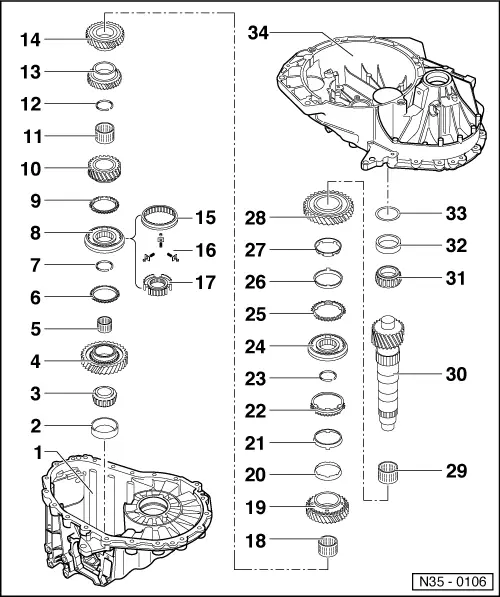

Dismantling and assembling output shaft (pinion shaft)

Dismantling and assembling output shaft (pinion shaft)

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

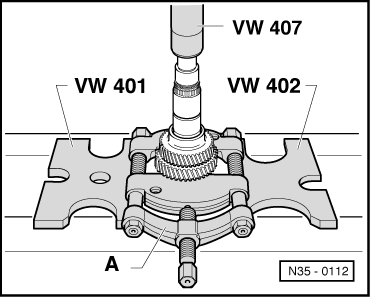

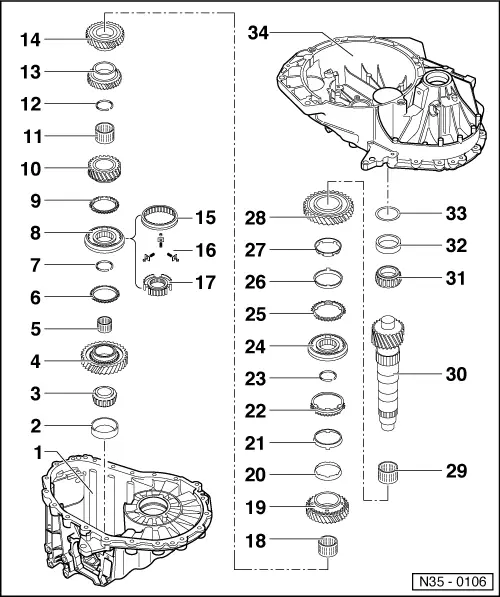

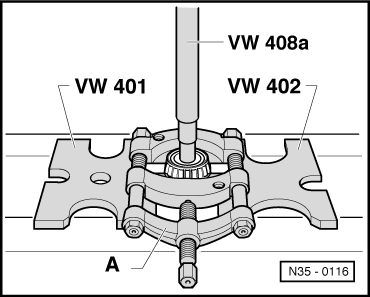

→ Fig.1 Pulling taper roller bearing outer race out from gearbox housing A - Counter support, e.g. Kukko 22/2 B - Internal puller 46...58 mm, e.g. Kukko 21/7 |

|

|

|

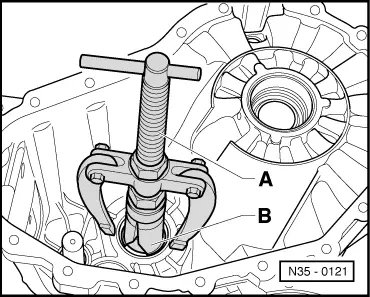

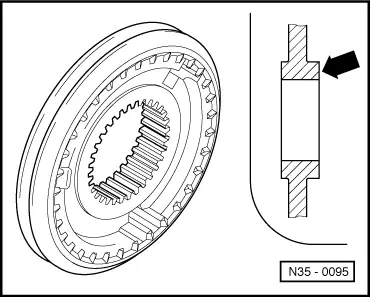

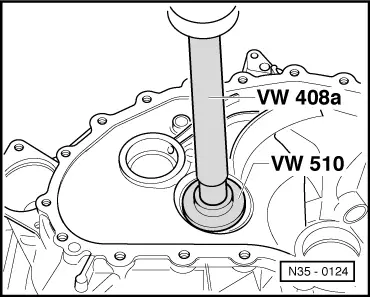

→ Fig.2 Pressing taper roller bearing outer race into gearbox housing |

|

|

|

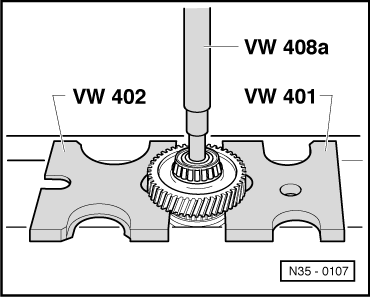

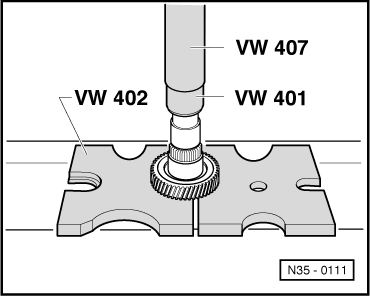

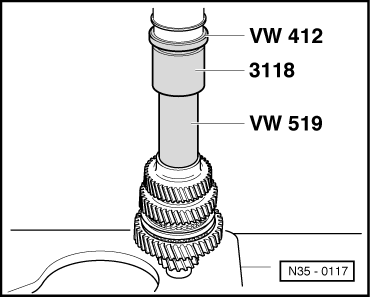

→ Fig.3 Pressing off taper roller bearing inner race

|

|

|

|

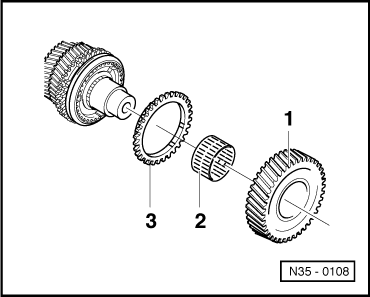

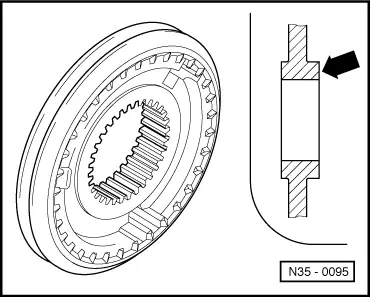

→ Fig.4 Removing reverse gear wheel

|

|

|

|

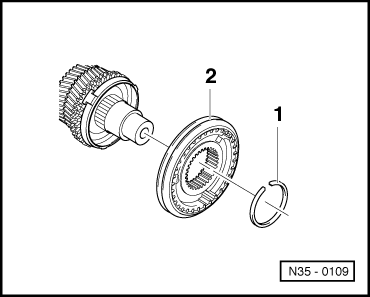

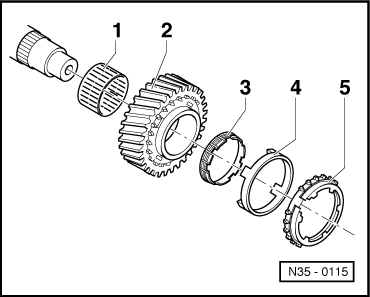

→ Fig.5 Removing 5th and reverse gear locking collar and synchro-hub

|

|

|

|

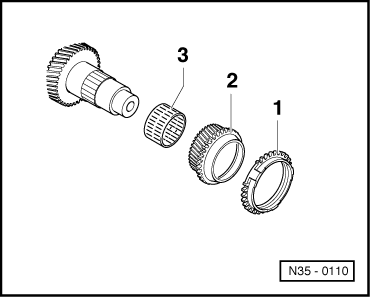

→ Fig.6 Removing 5th gear wheel

|

|

|

|

→ Fig.7 Pressing off 4th gear wheel

|

|

|

|

→ Fig.9 Removing 2nd gear wheel

|

|

|

|

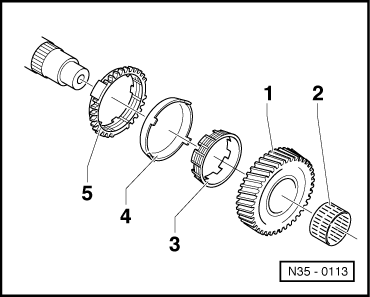

→ Fig.10 Removing 1st and 2nd gear locking collar and synchro-hub

|

|

|

|

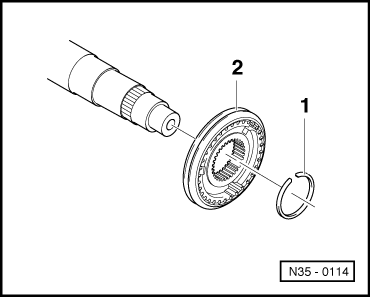

→ Fig.11 Removing 1st gear wheel

|

|

|

|

→ Fig.12 Pulling off taper roller bearing inner race A - Separating device 22 ... 115 mm, e.g. Kukko 17/2 |

|

|

|

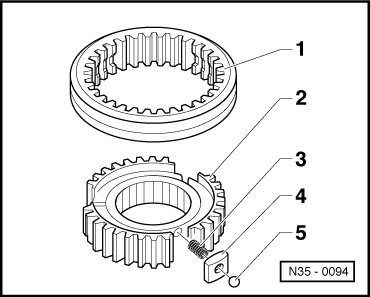

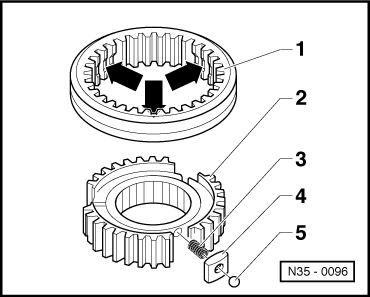

→ Fig.16 Installation position of 1st and 2nd gear locking collar/synchro-hub The wider shoulder of the synchro-hub (arrow) faces towards 2nd gear. |

|

|

|

→ Fig.17 Pressing on 3rd gear wheel Shoulder points towards 4th gear. |

|

|

|

→ Fig.18 Pressing on 4th gear wheel Shoulder points to 3rd gear.

|

|

|

|

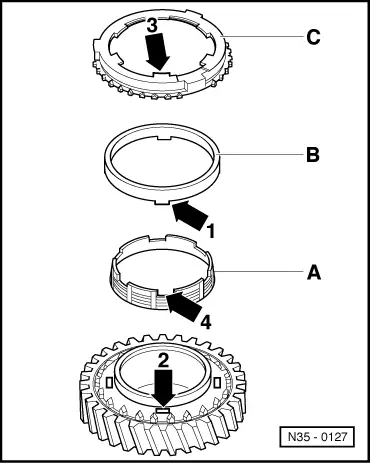

→ Fig.19 Installation position of 5th and reverse gear locking collar/synchro-hub The wider shoulder of the synchro-hub (arrow) faces towards 5th gear -B-. |

|

|

|

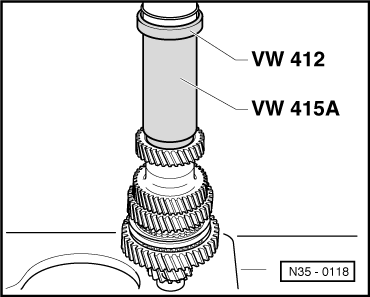

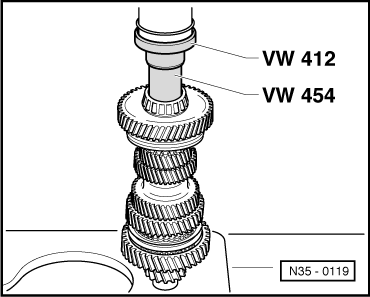

→ Fig.20 Pressing on taper roller bearing inner race |

|

|

|

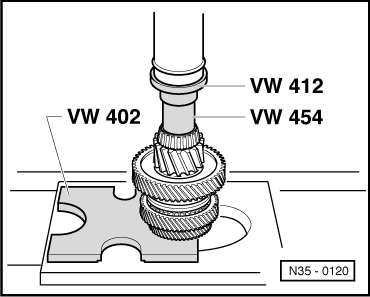

→ Fig.21 Pressing on taper roller bearing inner race |

|

|

|

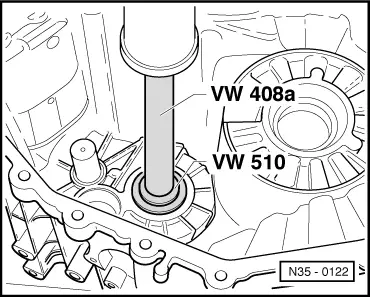

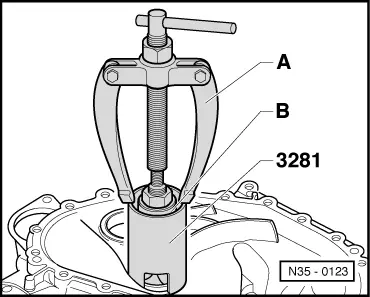

→ Fig.22 Pulling taper roller bearing outer race out from clutch housing A - Counter support, e.g. Kukko 22/2 B - Internal puller 46...58 mm, e.g. Kukko 21/7 |

|

|

|

→ Fig.23 Pressing taper roller bearing outer race into clutch housing |