Leon Mk1

|

|

|

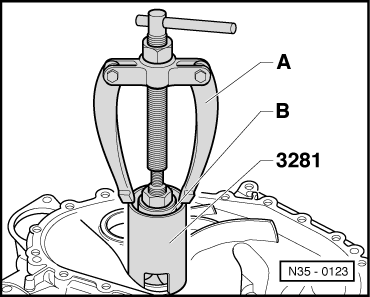

have been changed. Adjustment overview |

|

||||||||

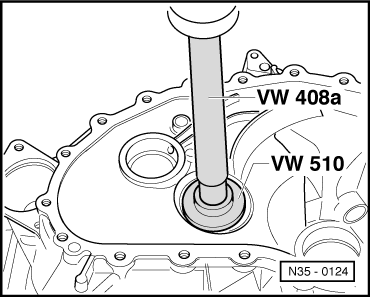

Note: This preparation is to be repeated for each subsequent measurement, otherwise the gauge will not return to the starting position.

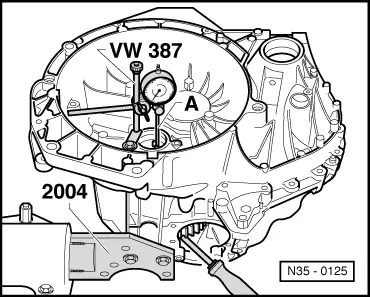

Determining thickness of shim The specified bearing preload is obtained by adding the gauge reading Example:

|

|

|||||

Table of "shims":

1) To determine shim add gauge reading to measurement shim |