| –

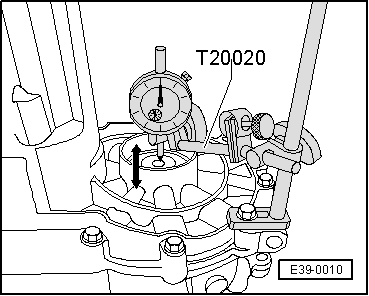

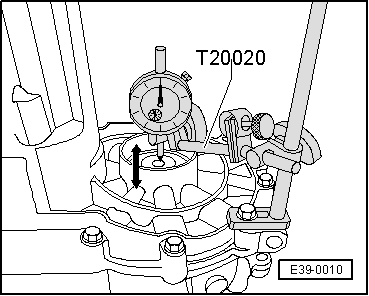

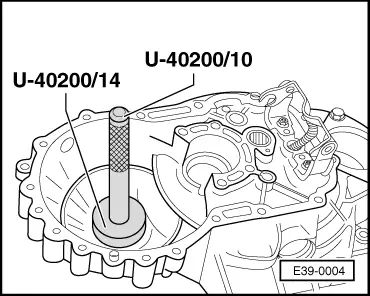

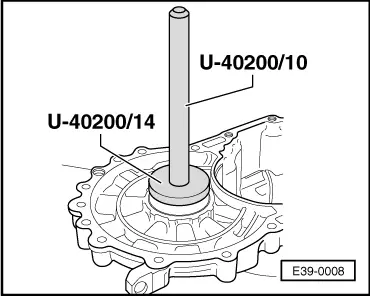

| Fit tool -T20020- on the gearbox casing with a dial gauge. Locate the end of the gauge on the differential, interplacing tool -U-40200/11-. |

| –

| Adjust the dial gauge to “0” with a pre-tension of 1 mm. |

| –

| Move the differerential alternately in the direction of the arrows. |

| –

| Take note of the meaurement obtained (e.g. 0.9 mm). |

Note! | When measuring do not turn the differential, because the roller bearings may settle and the reading would be erroneous. |

| Die vorgeschriebene Vorspannung für die Lager erreicht man durch die Addition eines konstanten Druckwerts (0,4 mm) zum bei der Messung des S1 erhaltenen Werts (im Beispiel: 0,90 mm). |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!