Leon Mk1

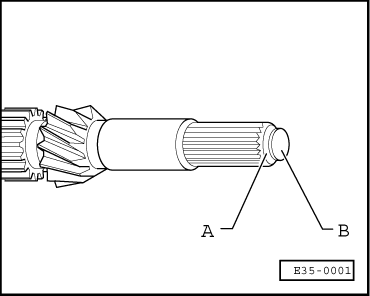

| Input shaft: dismantling and assembling |

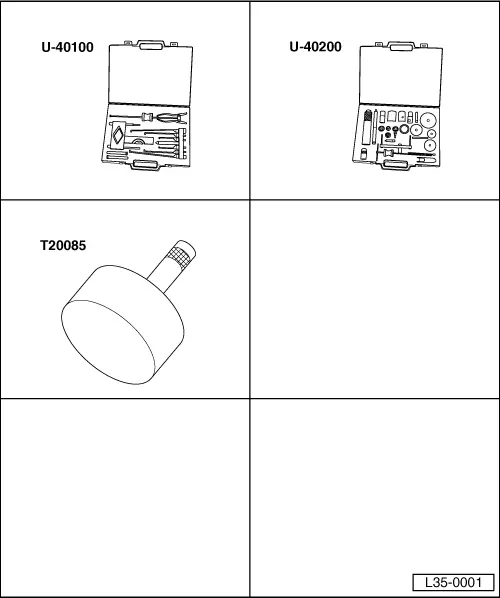

| Special tools and workshop equipment required |

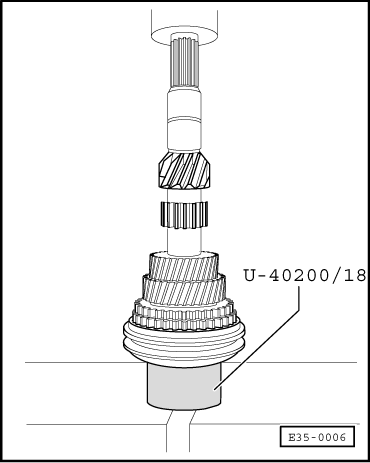

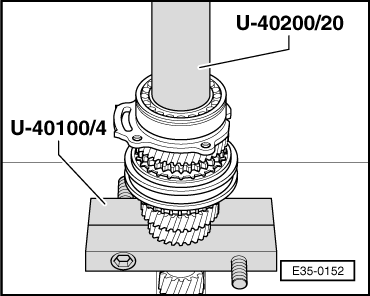

| t | Gearbox extractor set -U-40100- |

| t | Gearbox repair set -U-40200- |

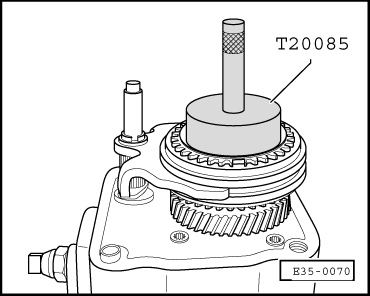

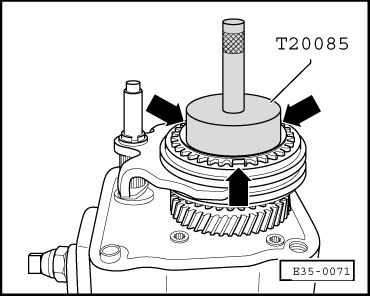

| t | Tool for removing/fitting stop ring 5th gear -T20085- |

Note!

Note!| Whenever new gears are fitted consult the technical data, → Chapter, Code letters, group numbers, ratios, filling quantities |

| 1 - | Bolt |

| q | 150 Nm |

| q | Renew |

| q | Removing and fitting → Chapter |

| 2 - | Plate spring |

| 3 - | Syncromesh assembly 5th gear |

| q | Removing and fitting → Chapter, Assembly sequence |

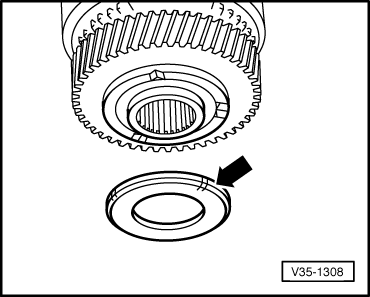

| 4 - | Stop ring |

| q | Stops the locking keys from being released |

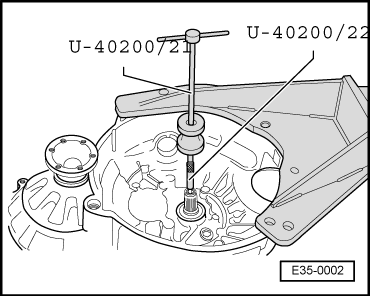

| q | Remove → Fig. |

| q | Fit → Fig. |

| 5 - | Spring |

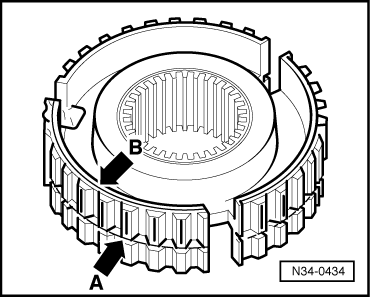

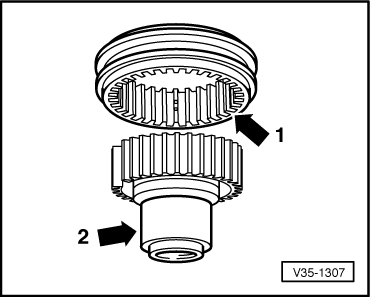

| 6 - | Sliding sleeve for 5th gear |

| q | Installation position → Fig. |

| 7 - | Syncromesh hub 5th gear |

| 8 - | Locking keyways |

| q | 3 units |

| 9 - | Countersunk bolt |

| q | 15Nm |

| q | M7 x 23 |

| q | 4 units |

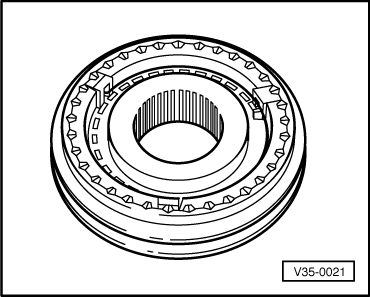

| 10 - | Ball bearing |

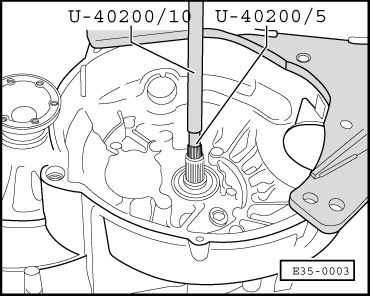

| q | Remove → Fig. |

| q | Fit → Fig. |

| 11 - | Fixing plate |

| q | Secures the ball bearing |

| 12 - | Sliding 4th gear |

| 13 - | Syncromesh ring for 4th gear |

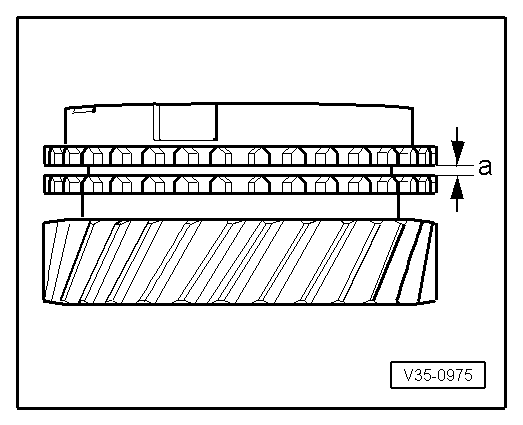

| q | Checking for wear → Fig. |

| 14 - | Safety ring |

| q | Renew |

| 15 - | 3rd and 4th syncromesh assembly |

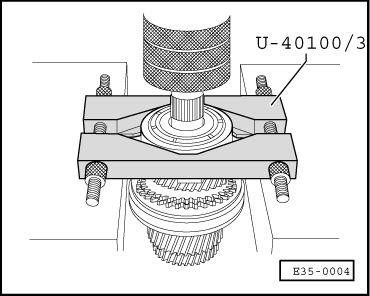

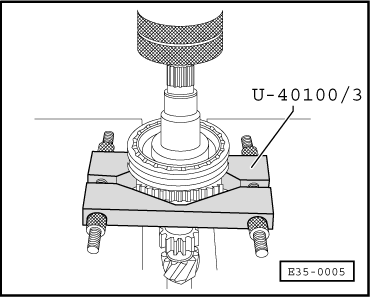

| q | Remove together with 3rd gear → Fig. |

| q | Syncromesh installation position , → Fig. |

| q | Assemble → Fig. |

| q | Fit → Fig. |

| 16 - | Sliding sleeve |

| 17 - | Syncromesh hub |

| 18 - | Locking keyways |

| q | 3 units |

| 19 - | Spring |

| 20 - | Clutch housing |

| 21 - | Clutch housing |

| 22 - | Needle roller bearing |

| q | For input shaft |

| q | Removing and fitting → Chapter, Assembly sequence |

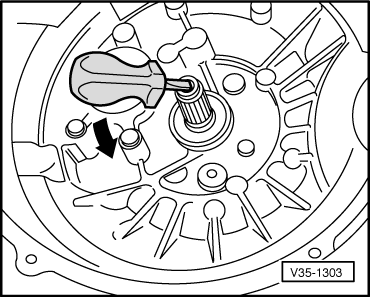

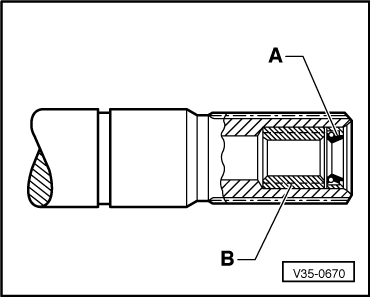

| 23 - | Oilseal for clutch pushrod |

| q | Can be replaced with the geabox removed (not dismantled) |

| q | Remove by levering with a screwdriver → Fig. |

| q | Installation position → Fig. |

| q | Fit → Fig. |

| 24 - | Bush for clutch pushrod |

| q | Can be replaced with the geabox removed (not dismantled) |

| q | Remove → Fig. |

| q | Installation position → Fig. |

| q | Fit → Fig. |

| 25 - | Sliding 3rd gear |

| 26 - | Syncromesh ring 3rd gear |

| q | Checking for wear → Fig. |

| 27 - | Gearbox casing |

| 28 - | Shim |

| q | For input shaft |

| q | See → Item |

| 29 - | Thrust washer |

| q | Installation position → Fig. |

| q | Once the 5th gear syncromesh ring has been fitted, → Item, fit the sliding 5th gear, → Item, on the syncromesh hub → Item |

| 30 - | Sliding 5th gear |

| 31 - | Syncromesh ring 5th gear |

| q | Checking for wear → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Syncromesh ring | Measurement “a” on a new syncromesh | Wear limit |

| 3rd gear 4th gear 5th gear | 1.15 ... 1.75 mm 1.3 ... 1.9 mm 1.3 ... 1.9 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|