Leon Mk1

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

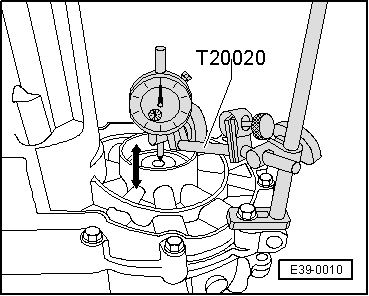

| Bearing play, measured value | Thickness of shim according to table |

| 0.70 mm | 0.95 mm |

|

| Bearing play | Shim |

| bearing clearance (mm) | Thickness (mm) |

| 0,303 … 0,449 0,450 … 0,499 0,500 … 0,549 | 0,650 0,700 0,750 |

| 0,550 … 0,599 0,600 … 0,649 0,650 … 0,699 | 0,800 0,850 0,900 |

| 0,700 … 0,749 0,750 … 0,799 0,800 … 0,849 | 0,950 1,000 1,050 |

| 0,850 … 0,899 0,900 … 0,949 0,950 … 0,999 | 1,100 1,150 1,200 |

| 1,000 … 1,049 1,050 … 1,099 1,100 … 1,149 | 1,250 1,300 1,350 |

| 1,150 … 1,199 | 1,400 |

Note

Note

|

|

|

|

|