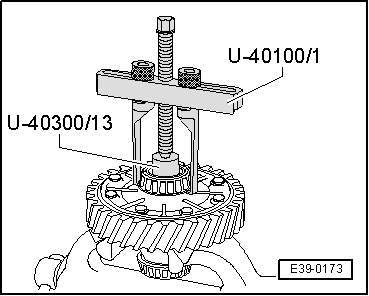

| Removing the roller bearing |

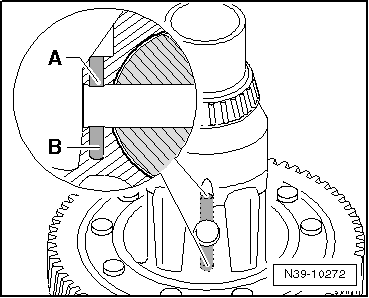

Note | The procedure and tools needed to remove the secondary shaft rear bearings outer tracks, are identical in the gearbox casing and the clutch housing. |

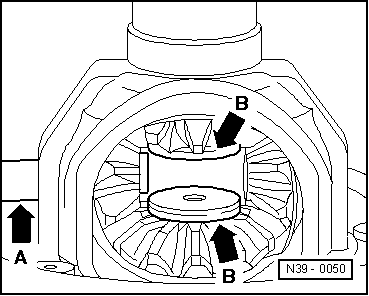

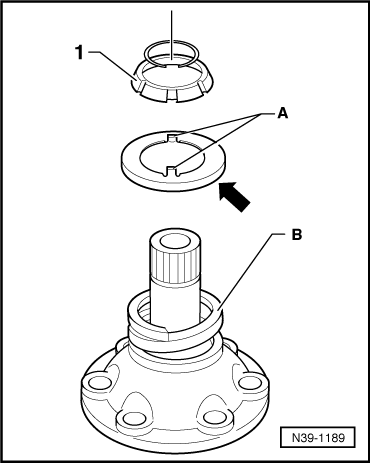

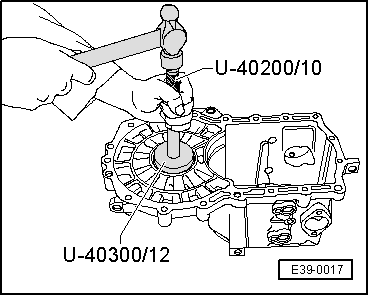

| –

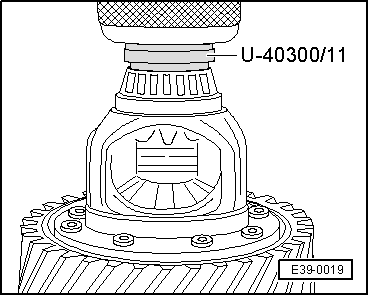

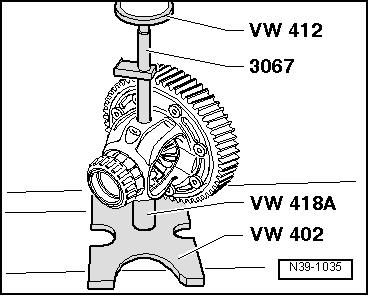

| Locate adapter -U-40300/13- on differential. |

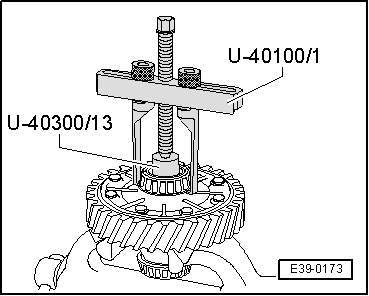

| –

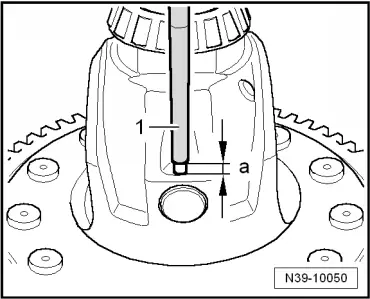

| Place the bridge adaptor -U 40100/1- on adaptor -U-40300/13-, ensuring that the claws are inserted into the notches in the differential casing. Remove the bearing. |

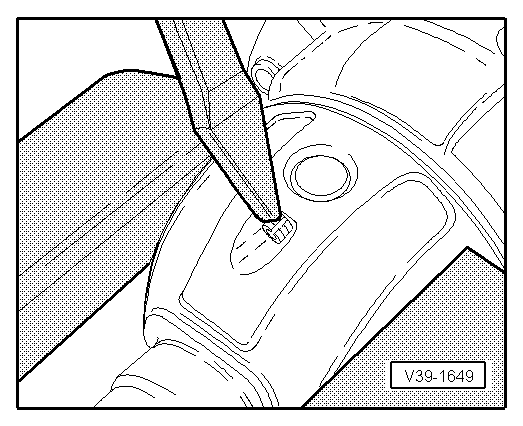

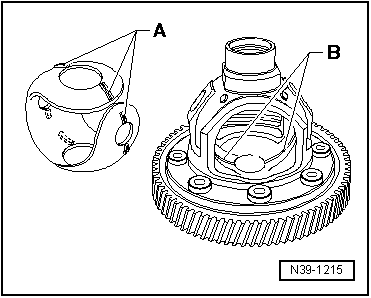

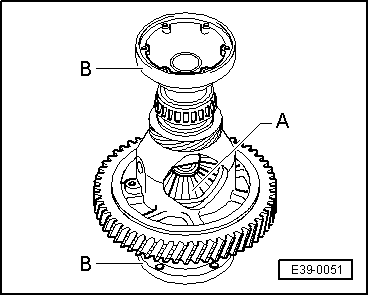

Note | If the bearing cage breaks during the extraction then use the kit -T20022- to remove the inner ring of the bearing. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note