| –

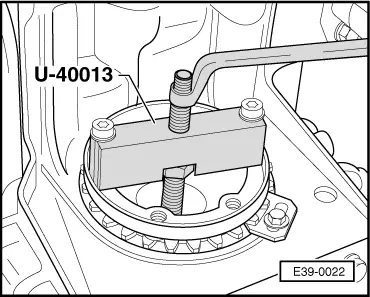

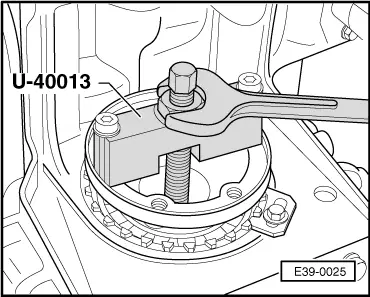

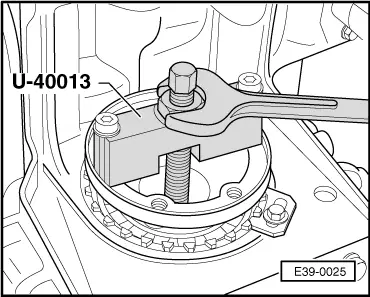

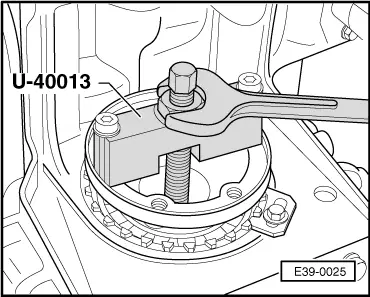

| Locate tool -U-40013- over the articulated flange and fit with two “M8” screws. |

| –

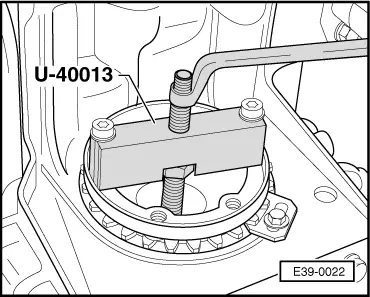

| Screw tool -U-40013- shaft into the flanged shaft extension rod. |

| –

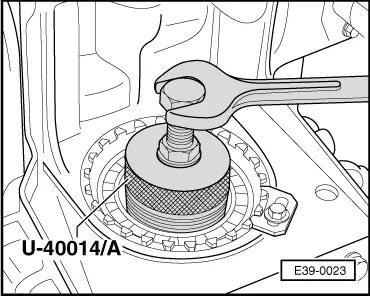

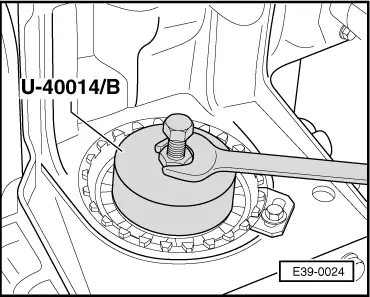

| Screw the tool shaft bolt until the flanged shaft is engaged. |

| –

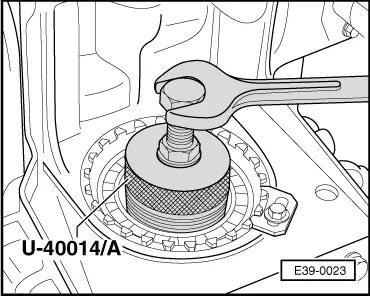

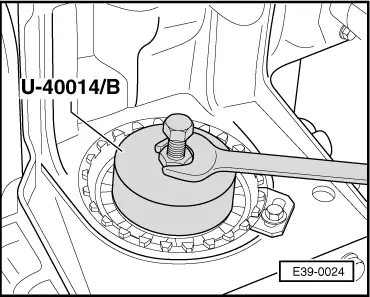

| Fit the new safety ring in the groove of the flanged shaft. To do this, use tool -A-81124-. |

| –

| Fit a new protective cap on the articulated flange. |

| –

| Fit the drive shaft on the gearbox articulated flange using the appropriate spanner on tool -U-40020-. |

| –

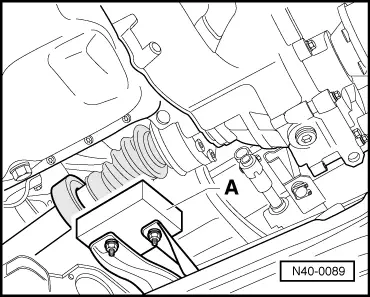

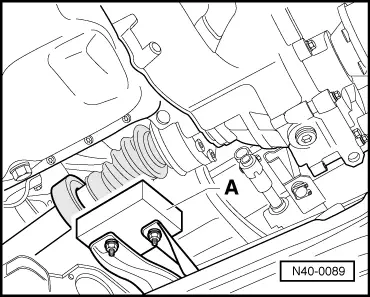

| Fit counterweight -A- to the sub-frame. |

| Fitting position: in accordance with mark made for removal. If no mark was made, the counterweight should be fitted to the sub-frame in such a way that the greatest distance between the edge of the counterweight and the securing bolts faces the front. |

| –

| Fit the heat shield for the flanged shaft, if applicable. |

| –

| With the ignition switched off, connect battery earth strap. |

|

|

|