Leon Mk1

| Valve control: repairing |

Note!

Note!| t | The cylinderheads with cracks between the valve seats can still be used without decrease in their useful life, so long as the cracks are no wider than 0.5 mm max. |

| t | Before installation work, oil the support and slide surfaces. |

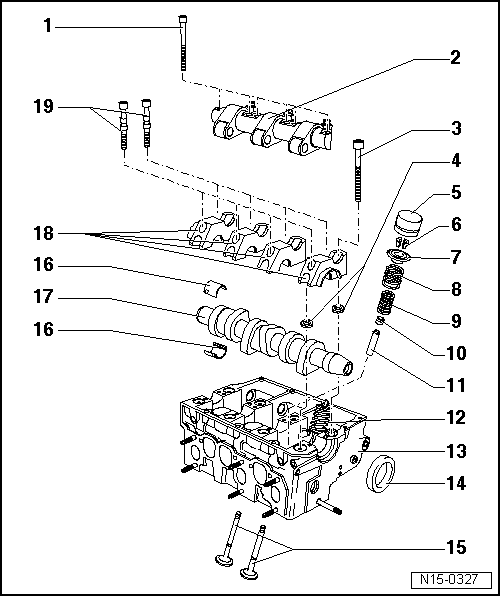

| 1 - | 20 Nm + 1/4 turn (90°) |

| q | Replace |

| q | Follow the installation order when loosening and tightening → Fig., Camshaft: removing and installing |

| 2 - | Rocker shaft |

| 3 - | Cylinderhead bolt |

| q | Replace |

| q | Follow the installation order when loosening and tightening → Anchor, Cylinderhead: removing and installing |

| q | Before installation, fit the washers → Item in the cylinderhead |

| 4 - | Washer |

| q | For the cylinderhead bolts |

| 5 - | Hydraulic plunger |

| q | Before removing, remove the half-bearings of the camshaft |

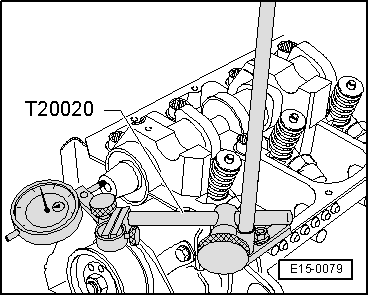

| q | Do not swap them |

| q | With hydraulic compensation of valve play |

| q | Place with the slide surface down |

| q | Before installation test the axial play of the camshaft → Fig. |

| q | Lubricate the slide surface |

| 6 - | Half-cones |

| 7 - | Valve spring plate |

| 8 - | Valve spring, exterior |

| q | Remove and install: Cylinderhead: removed: with -T20034/1- installed: → Item, replace the valve stem seals |

| 9 - | Valve spring, interior |

| q | Remove and install: Cylinderhead: removed: with -T20034/1- installed: → Item, replace the valve stem seals |

| 10 - | Valve stem seal |

| q | Replace → Item |

| 11 - | Valve guide |

| q | Test → Item |

| q | Replace → Item |

| q | Repair guides, with collar |

| 12 - | Pump injector |

| q | Remove and install → Chapter |

| 13 - | Cylinderhead |

| q | Bear in mind the note → Anchor |

| q | Re-cut the valve seats → Chapter |

| 14 - | Seal |

| q | Do not apply more oil or grease to the seal lip |

| q | Before installation, clean excess oil from the camshaft journal with a clean cloth |

| q | For installation, cover the slot in the camshaft cone (e.g. with tape) |

| q | Remove and install → Chapter |

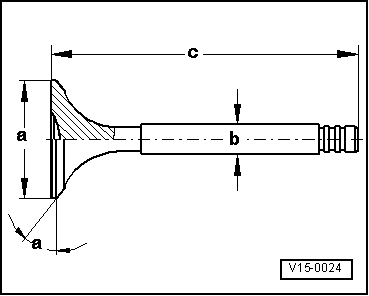

| 15 - | Valves |

| q | Valve dimensions → Fig. |

| 16 - | Half-bearings |

| q | Do not swap the used half-bearings (mark them) |

| q | Check that the cylinderhead and the fixing flanges fit well in the caps |

| 17 - | Camshaft |

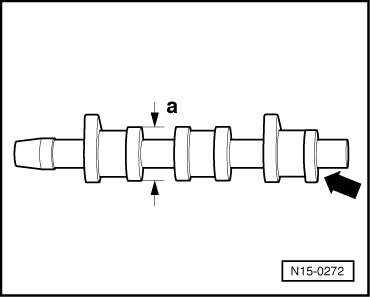

| q | Test the axial play → Fig. |

| q | Remove and install → Fig. |

| q | Test the radial play with Plastigage Wear limit: 0.11 mm |

| q | Eccentricity: max. 0.01 mm |

| q | Identification and distribution timing → Fig. |

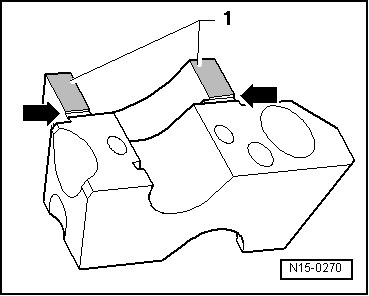

| 18 - | Cap |

| q | Installation order → Fig., Camshaft: removing and installing |

| q | Cap 4 is marked as cap 5 |

| q | For installation, seal the contact surfaces of caps 1 and 4 with -AMV 17400401- → Fig. |

| 19 - | 20 Nm + 1/4 turn (90°) |

| q | Replace |

Note!

Note!

|

|

Note!

Note!

|

|

| Dimension | Intake valve | Exhaust valve | |

| Ø a | mm | 35.95 | 31.45 |

| Ø b | mm | 6.980 | 6.956 |

| c | mm | 89.95 | 89.95 |

| α | ∠° | 45 | 45 |

|

|

| Cylinder 3 -arrow- | 045 C | ||

|

| Intake opens after TDC | 15.8° | ||

| Intake closes after BDC | 25.3° | ||

| Exhaust opens before BDC | 28.2° | ||

| Exhaust closes before TDC | 18.7° | ||