| –

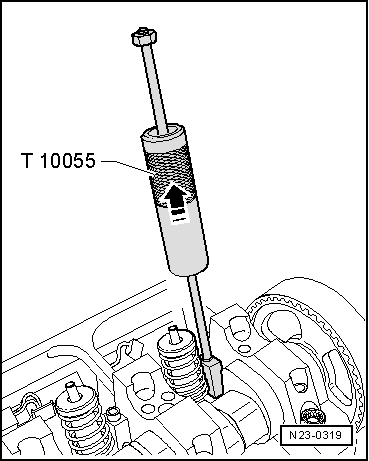

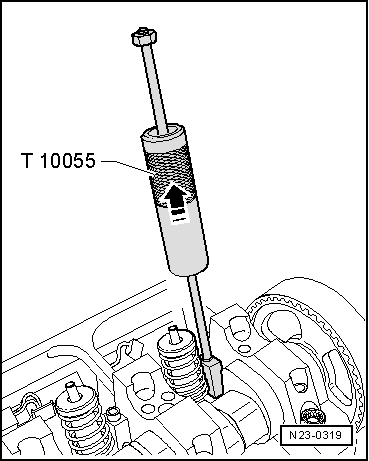

| Fit the extractor -T10055A- into the slot on the side of the injector pump instead of the attachment block. |

| –

| Carefully pull injector-pump assembly out of cylinder head seat with gentle taps |

Note | t

| New injection pumps are supplied with O-rings and the thermal protection joint. |

| t

| If a new injector pump unit is being fitted, the corresponding adjustment bolt on the rocker must also be replaced. |

| t

| When a used injection pump is refitted, the O-rings and the thermal protection joint must be replaced → Chapter. |

| t

| The rocker adjuster screw and the spherical pin of the injector pump should be replaced whenever the injector pumps are adjusted. |

| t

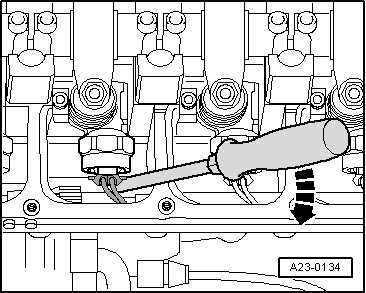

| Grease the contact surfaces between the spherical head pin and adjustment bolt using → Parts Catalogue. |

| –

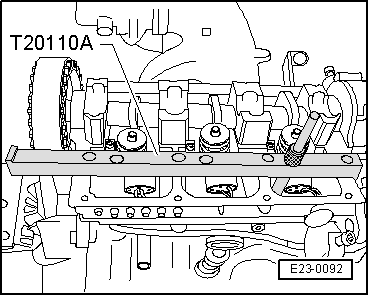

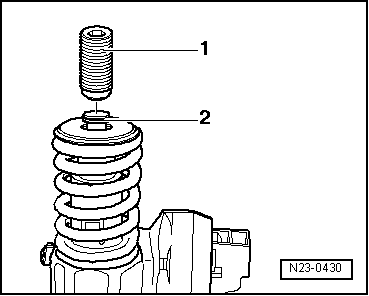

| Before fitting the injector pump, check that the 3 O-rings, the thermal protection joint and securing are seated correctly. |

Note | The O-rings must not be twisted. |

| –

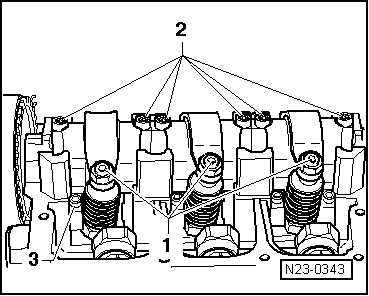

| Oil all of the O-rings and fit the injector pump very carefully into its allotment on the cylinder head. |

| –

| Press evenly, insert the injection pump to the limit of its allotment on the cylinder head. |

| –

| Fit the attachment stopper into the lateral groove of the injection pump. |

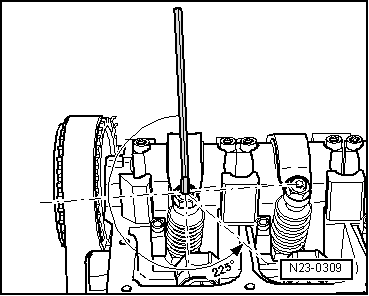

Note | If the injection pump is not perpendicular to the attachment stopper, the attachment bolt may come out. Due to this fact, damage may occur to the injection pump and the cylinder head. |

| –

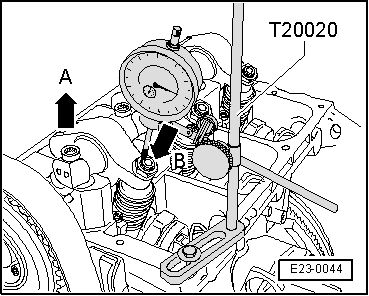

| To avoid this the injection pump must be placed as follows: |

| –

| Screw in the new attachment bolt in the attachment block to the point where the injection pump may still rotate a little. |

| –

| Place the injection pump so that it is perpendicular to the allotments for the camshaft. |

Note | There are two models of injection pump. One of them is equipped with a nut for the larger electronic valve. For this reason, follow the specific instructions for each one of these as follows: |

| Injection pump with larger electronic valve nut |

|

|

|

Note

Note

Note

Note Note

Note Note

Note Note

Note