Leon Mk1

| Engine: dismounting |

| Special tools and workshop equipment required |

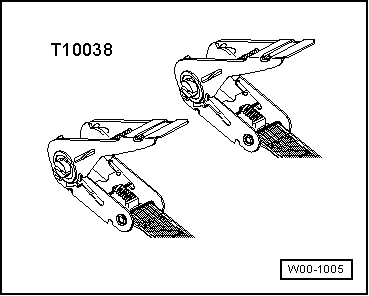

| t | Hose clamps -3094-, see equivalent → Anchor |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | Torque wrench -V.A.G 1332-, see equivalent → Anchor. |

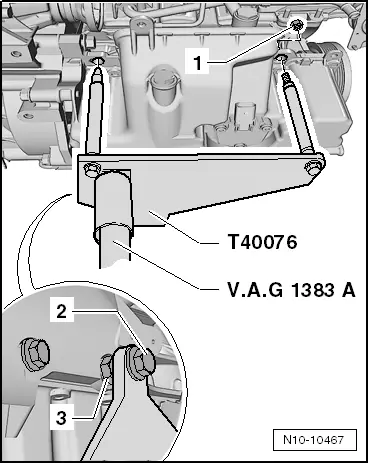

| t | Engine/gearbox crane -V.A.G 1383 A-, see equivalent → Anchor |

| t | Stepladder -VAS 5085-, see equivalent → Anchor |

| t | Engine bracket -T40076-, see equivalent → Anchor |

| t | Transport lock for the decoupling element -T10403-, see equivalent → Anchor |

| t | Torque wrench -V.A.G 1332-, see equivalent → Anchor. |

| t | Engine sealing plug set -VAS 6122-, see equivalent → Anchor |

| t | Collector tray for workshop crane -VAS 6208-, see equivalent → Anchor |

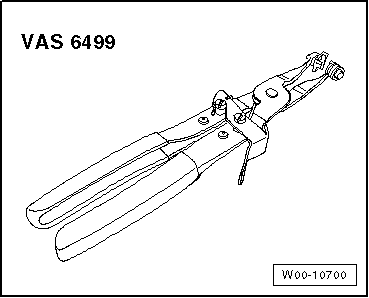

| t | Hose clamp pliers -VAS 6340-, see equivalent → Anchor |

| t | Grease (vehicles with manual gearbox) -G 000 100- |

| t | Cable tie |

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

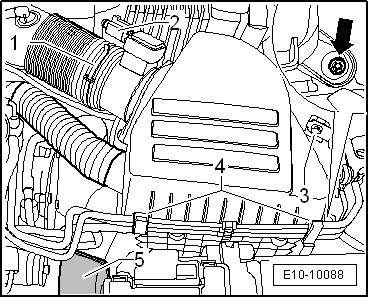

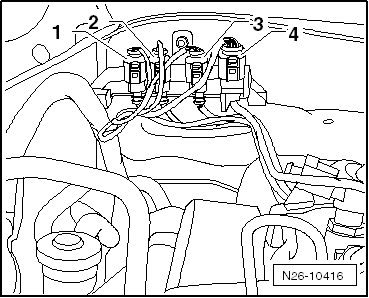

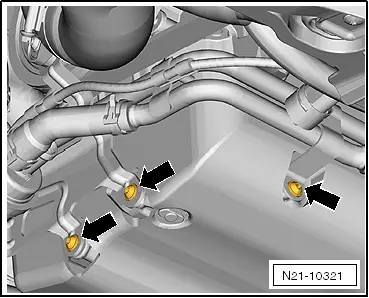

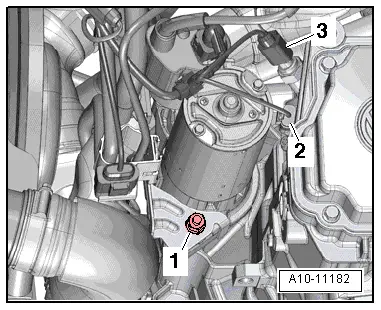

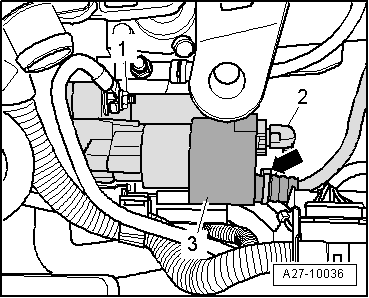

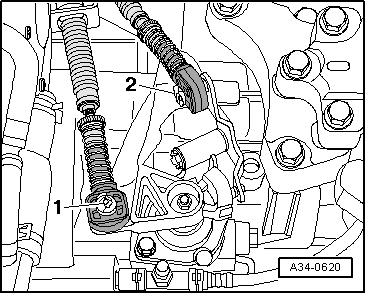

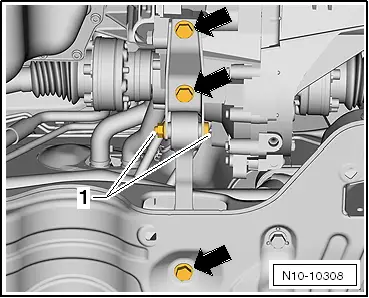

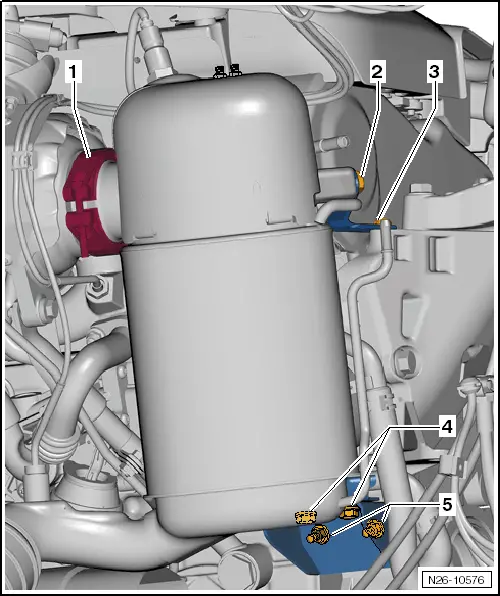

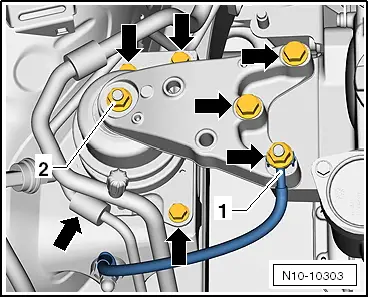

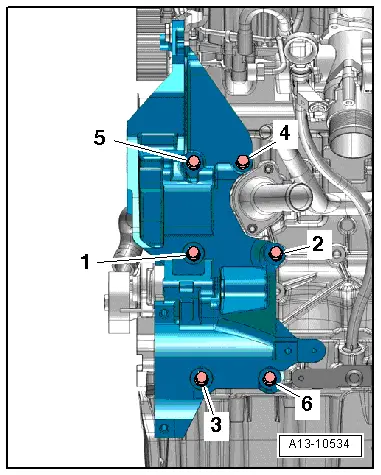

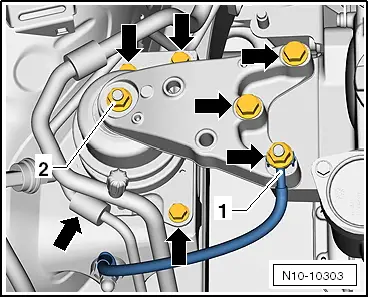

| 1. | Remove the fixing bracket -1- between the particle filter and the exhaust gas turbocharger. | |

| 2. | Remove bolts -2 ... 3-. | |

| 3. | Remove bolts -4-. | |

| 4. | Unscrew nuts -5- | |

Note

Note

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

WARNING

WARNING Caution

Caution