Leon Mk1

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

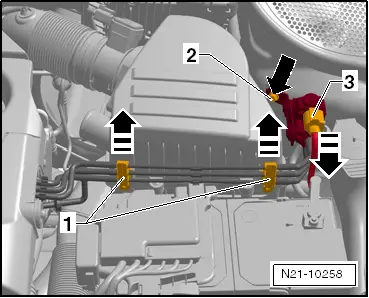

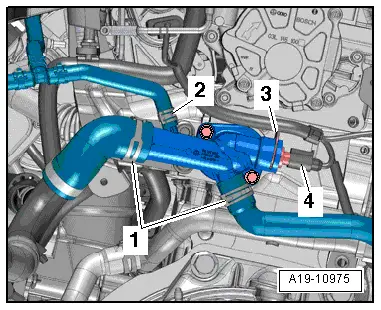

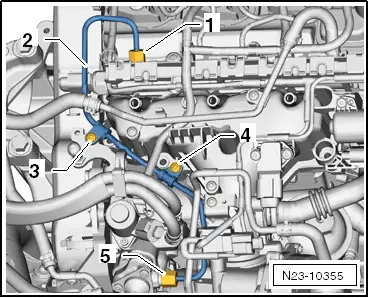

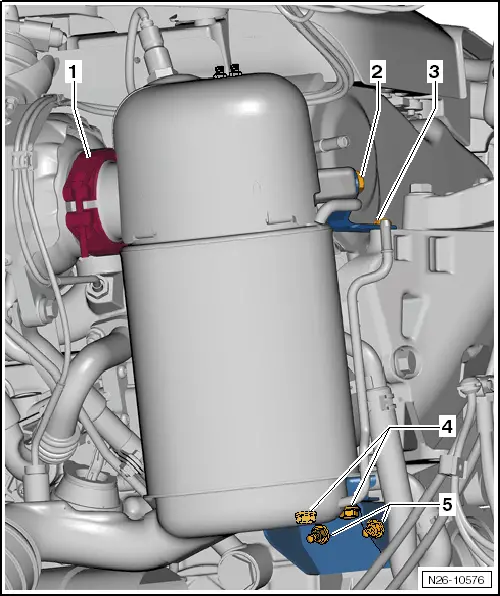

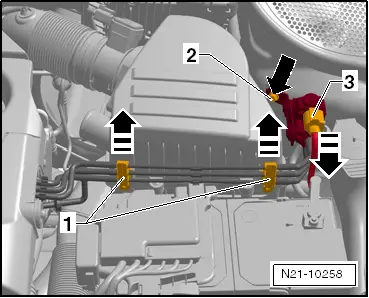

| 1. | Remove securing clamp between particulate filter and turbocharger | |

| 2. | Unscrew bolts and nuts -2 … 3- | |

| 3. | Remove bolts -4-. | |

| 4. | Unscrew nuts -5- | |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution