| –

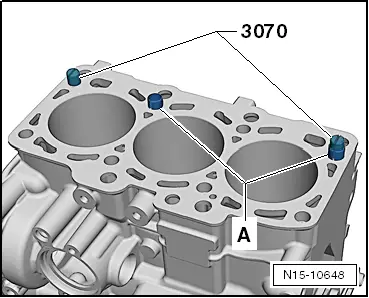

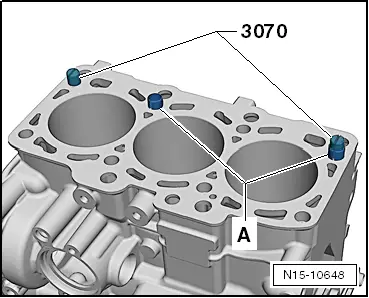

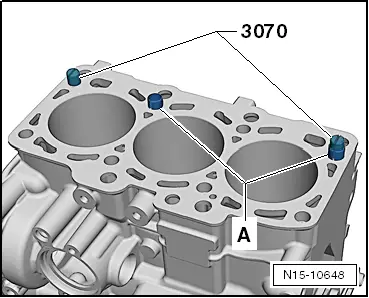

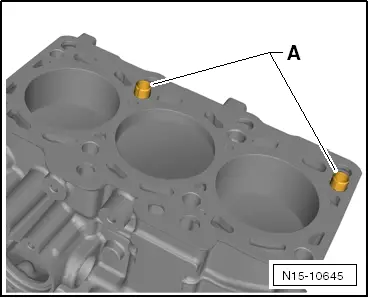

| To centralise, screw guide pins -3070/9- into outer holes on inlet side. |

Note | t

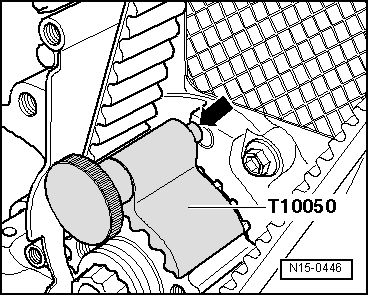

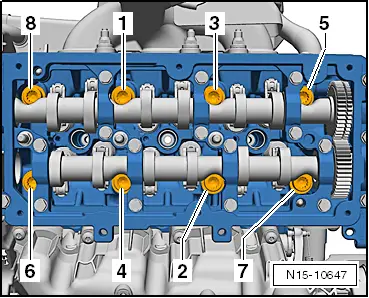

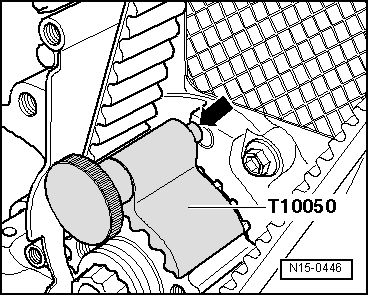

| Position tensioning roller on studs when fitting cylinder head. |

| t

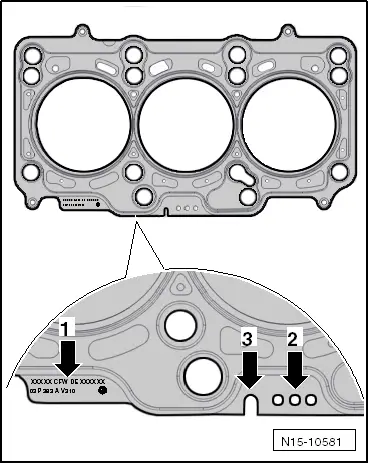

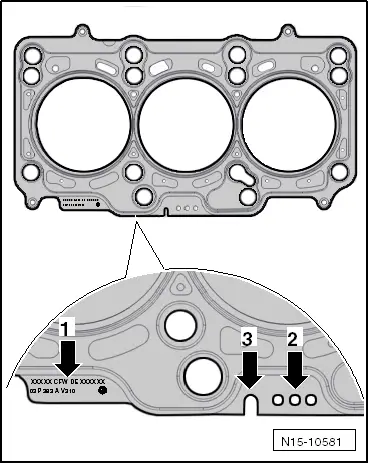

| If the cylinder head gasket or cylinder head have been replaced, select the new cylinder head gasket according to the number of holes on the old cylinder head gasket. |

| t

| If parts of the crankshaft assembly have been renewed, the new cylinder head gasket must be selected by measuring the piston projection at „TDC“ → Chapter. |

| –

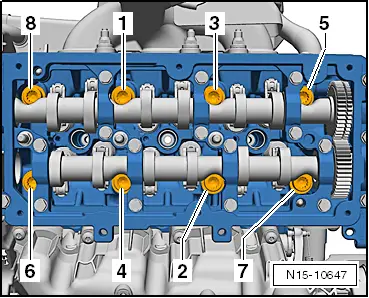

| Screw in 8 cylinder head bolts by hand until they make contact. |

| –

| Unscrew guide pins -3070/9- through bolt holes in cylinder head and screw in remaining cylinder head bolts by hand until they make contact. |

|

|

|

Note

Note

Note

Note