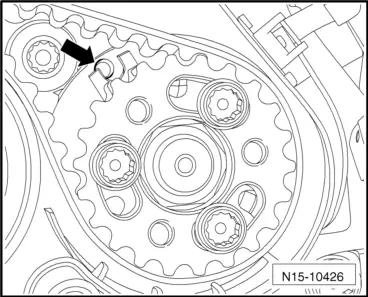

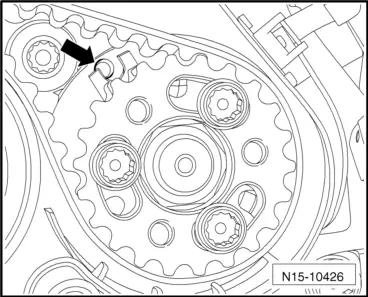

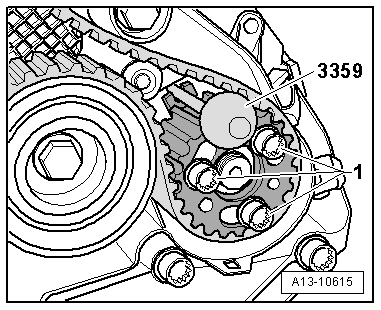

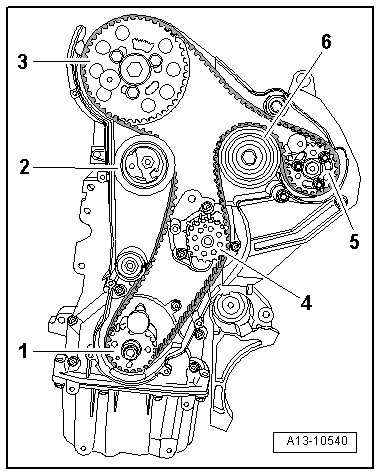

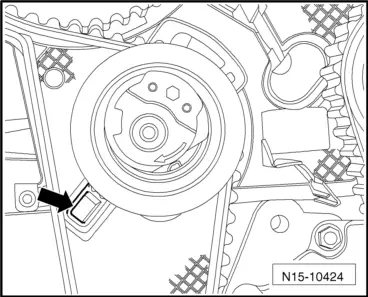

| During the following check, only the camshaft and the crankshaft are locked. It is very difficult to find the securing position of the high-pressure pump hub again. However, a slight deviation -arrow- does not influence the engine operation. |

| t

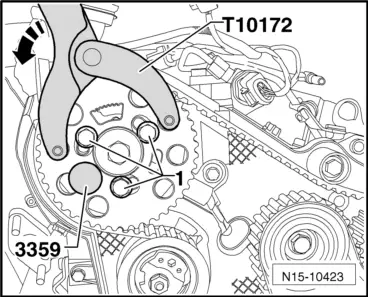

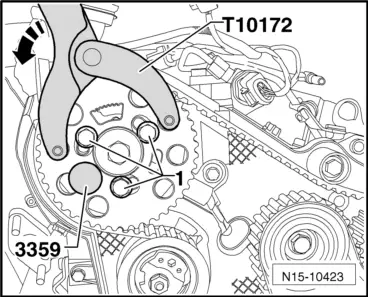

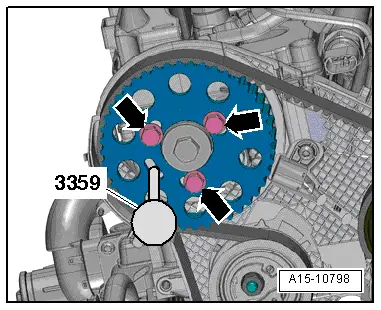

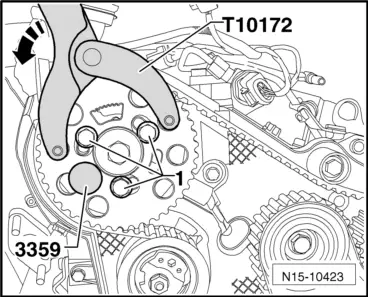

| Camshaft hub can be locked with locking pin -3359-. |

| t

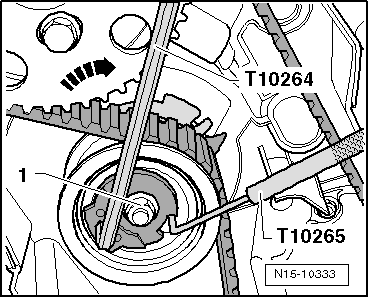

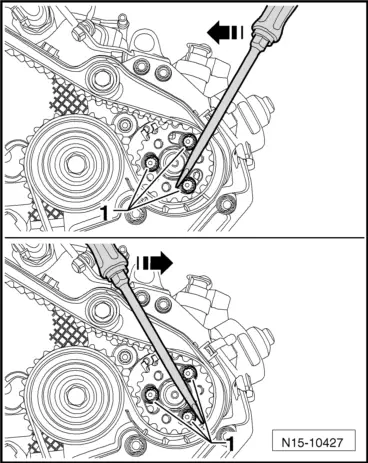

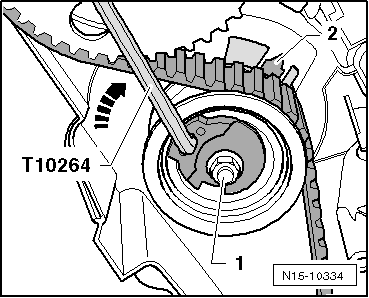

| Tensioner lug is centred or a max. of 5 mm to the right of the slot on the base plate. |

| If hub on camshaft cannot be locked: |

| –

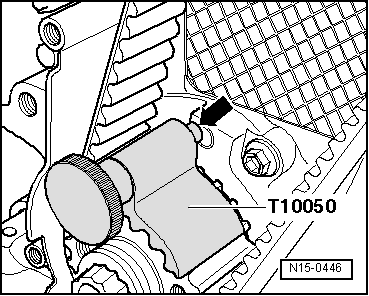

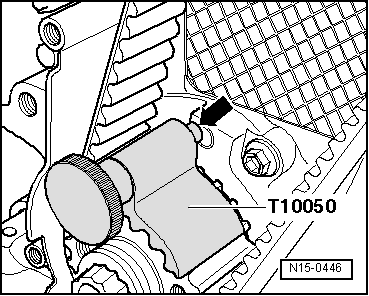

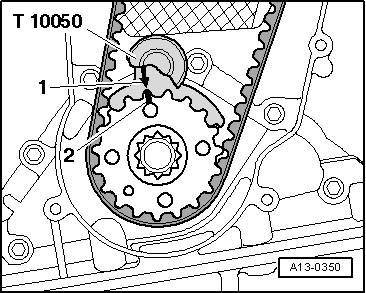

| Pull crankshaft stop -T10050- back until pin uncovers hole. |

| –

| Turn crankshaft out slightly past TDC by turning it in the opposite direction of engine rotation. |

| –

| Now turn crankshaft slowly in direction of engine rotation until camshaft hub can be secured in position. |

| –

| After locking, loosen securing bolts of crankshaft toothed belt sprocket. |

| If pin of crankshaft stop -T10050- is on left side of bore: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note