Leon Mk1

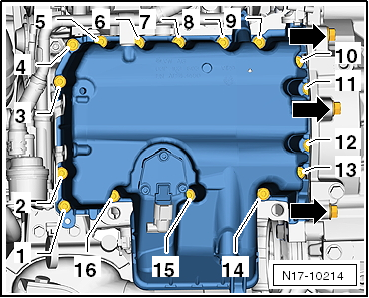

| Assembly overview - parts of lubrication system |

| 1 - | cylinder block |

| 2 - | Seal |

| q | Replace |

| 3 - | Oil filter bracket |

| q | With engine bracket |

| q | Dismantling and assembling → Chapter. |

| q | Checking engine oil cooler for leaks → Chapter |

| 4 - | Bolt. |

| q | Replace |

| q | 14 Nm and then turn 180° further |

| q | First fit upper left and lower right bolts and then tighten all four bolts diagonally. |

| 5 - | Oil dipstick |

| q | Oil level must not be above max. mark on dipstick! |

| q | Marks → Chapter |

| 6 - | Bolt. |

| q | 10 Nm |

| 7 - | Bolt. |

| q | 10 Nm |

| 8 - | Noise insulation |

| 9 - | O ring |

| q | Replace |

| 10 - | Oil level/oil temperature sender -G266- |

| q | Black connector, 3-pin |

| q | removing and fitting → Chapter |

| 11 - | Bolt. |

| q | 10 Nm |

| 12 - | Oil sump screws |

| q | 15 Nm |

| q | Tighten the bolts in 3 stages → Fig. |

| 13 - | Oil drain plug |

| q | 30 Nm |

| 14 - | Oil pan |

| q | Clean sealing surface before installing |

| q | Install with silicone sealant -D 176 501 A1- → Chapter. |

| 15 - | Bolts for the cover |

| q | 5 Nm |

| 16 - | Cover |

| q | Clean if dirty |

| 17 - | Balance shaft assembly with oil pump |

| q | removing and fitting → Chapter |

| 18 - | Tighten sealing flange bolts |

| q | 15 Nm |

| q | First fit upper left and lower right bolts and then tighten all four bolts diagonally. |

| 19 - | Sealing flange |

| q | With shaft seal |

| q | Must sit on dowel sleeves |

| q | removing and fitting → Chapter |

| q | Do not additionally oil or grease the oil seal sealing lip. |

| q | Before fitting, clean the remains of oil on the crankshaft journal using a clean cloth. |

Note

Note

|

|

| stage: | Bolts | Tightening torque |

| 1. | -1 … 20- | Diagonally, 5 Nm |

| 2. | -Arrows - | 40 Nm |

| 3. | -1 … 20- | Tighten in stages and in diagonal sequence; final torque 13 Nm. |