Leon Mk1

|

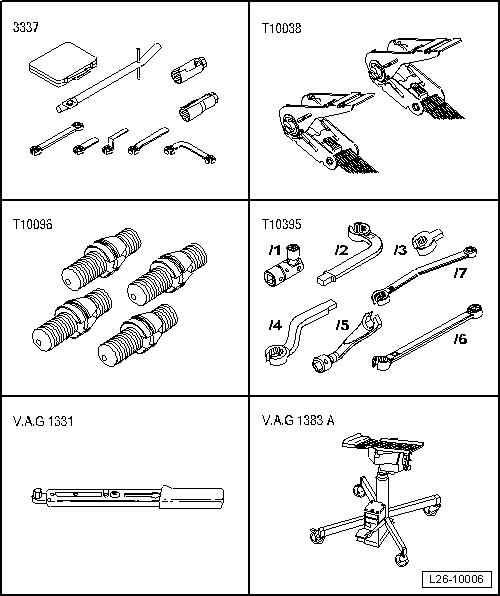

| Special tools and workshop equipment required |

| t | Box wrench set for lambda probe -3337-, see equivalent → Anchor |

| t | Tension belt -T00038-, see equivalent → Anchor |

| t | Adjustment tool -T10096-, please see Correspondence → Anchor |

| t | Adjustment tool -T10395-, see equivalent → Anchor |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | Engine/gearbox crane -VAG 1383A-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|