| Checking delivery pressure of fuel pump |

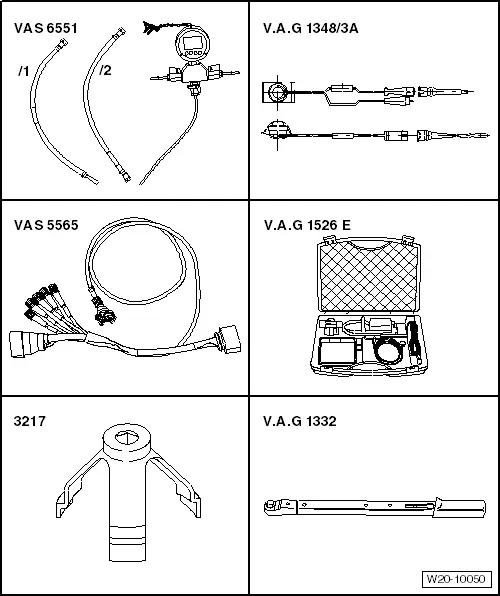

| Special tools and workshop equipment required |

| t

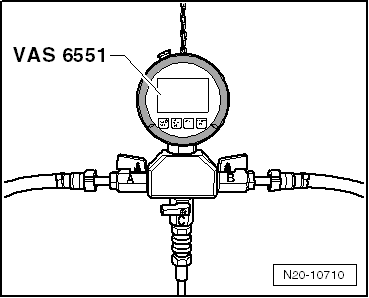

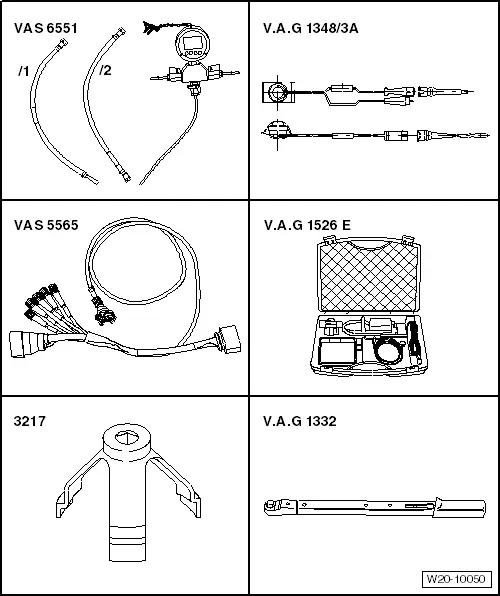

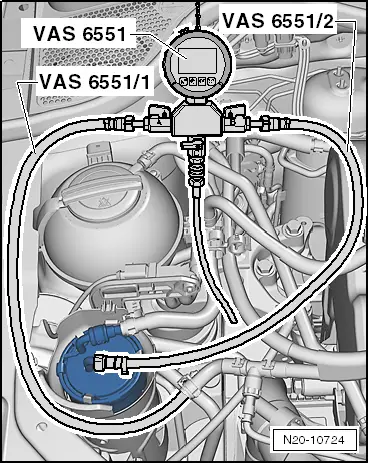

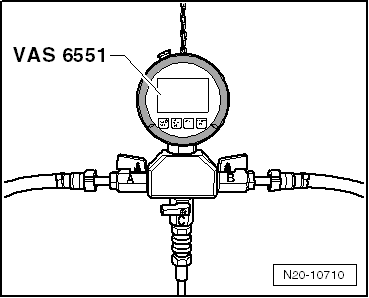

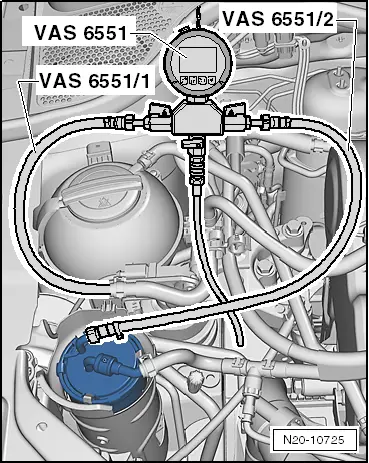

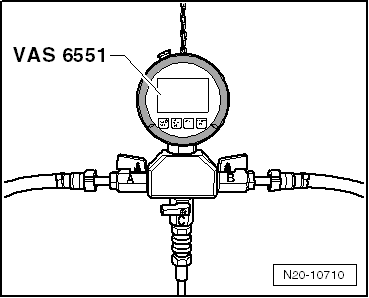

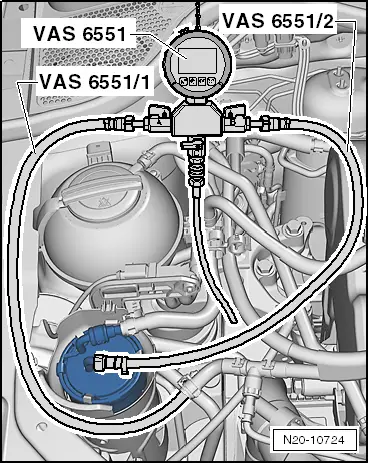

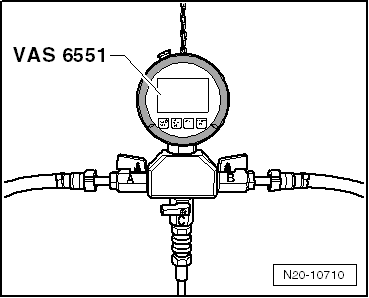

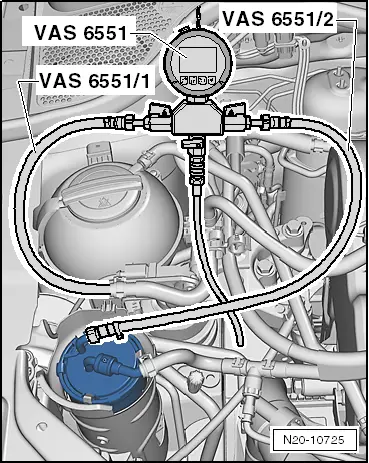

| Pressure gauge -VAS 6551-, see equivalent → Anchor |

| t

| Hose adapter -VAS 6551/1- |

| t

| Hose adapter -VAS 6551/2- |

| t

| Vehicle diagnostic, testing and information system -VAS 505X-, see equivalent → Anchor |

| l

| Battery voltage at least 12 V |

| l

| This measurement does not depend on the fuel level but a minimum level of 5 l is necessary. |

| l

| Ensure that vehicle is placed on a level surface. |

| l

| Ensure that fuel hoses and lines in engine compartment and on underbody are not closed through damage (kinks). |

| l

| All electrical consumers, e.g. lights and rear window heating, must be switched off. |

WARNING | Fuel supply line is pressurised. Wear eye protection and protective clothing to avoid eye injuries and skin contact. Before loosening hose connections, wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

| »Carry out the following work sequence« |

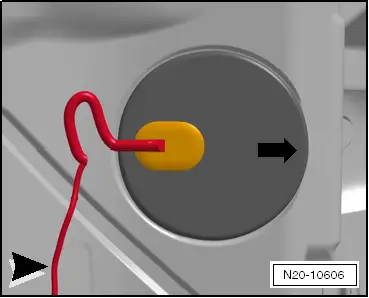

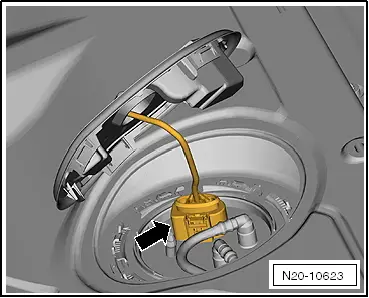

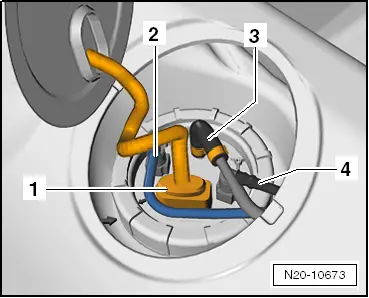

| –

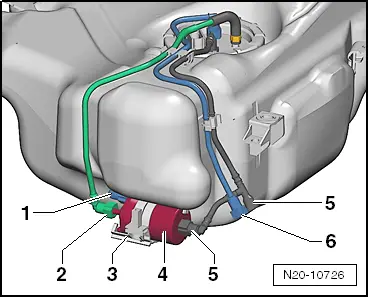

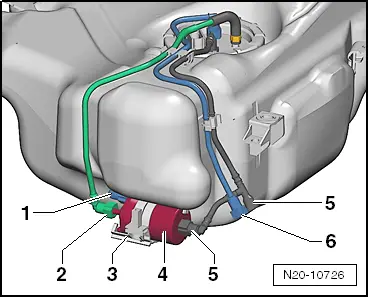

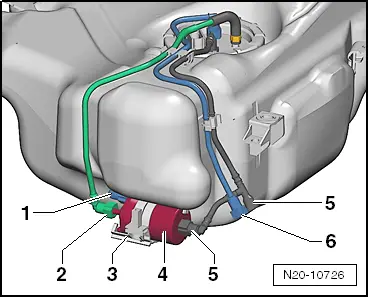

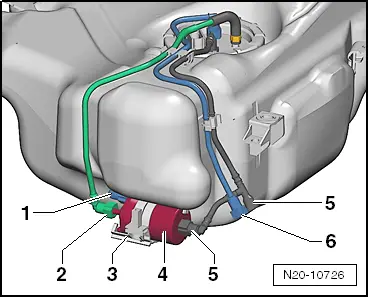

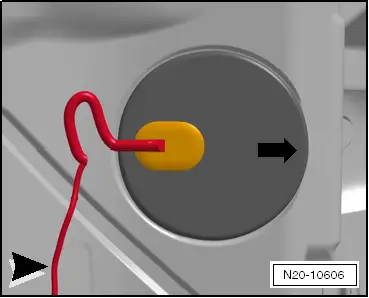

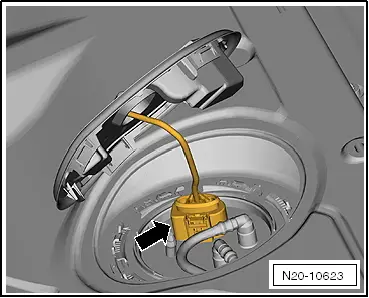

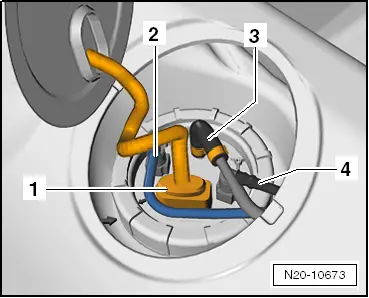

| Push connector coupling on fuel filter → Item, fuel supply line to high-pressure pump, forwards onto filter connection. Press catches in and hold, pull fuel supply line from fuel filter. |

| –

| Collect escaping fuel with a cleaning cloth. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note