| –

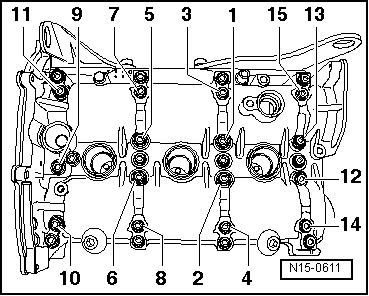

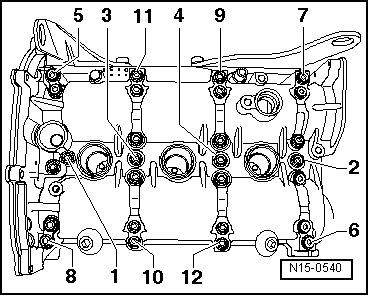

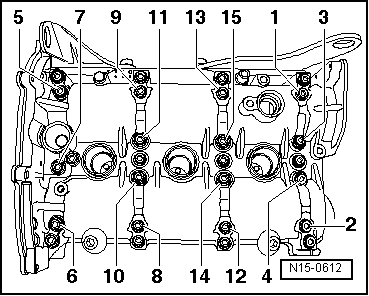

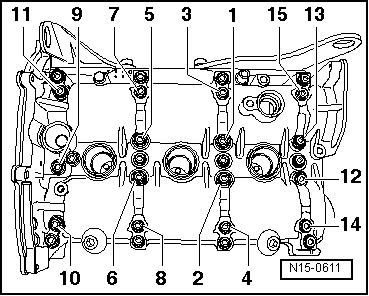

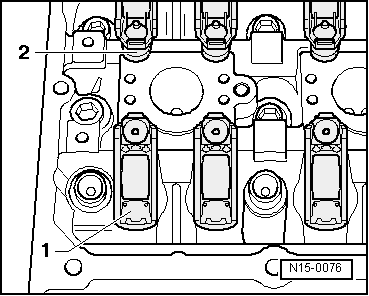

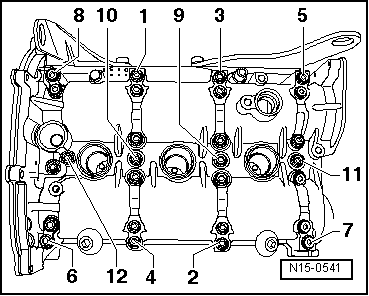

| Manually tighten the camshaft bearing bolts in the sequence indicated. |

| Take care not to tilt the camshaft bearing caps. Tightening torque: 10 Nm +1/4 turn further (90º) |

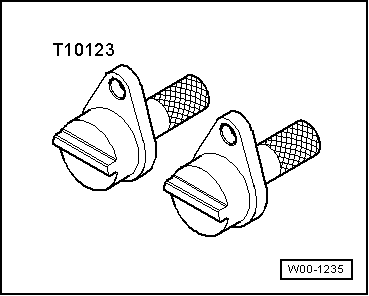

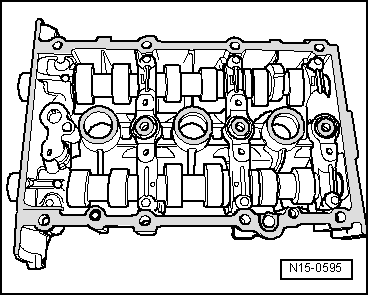

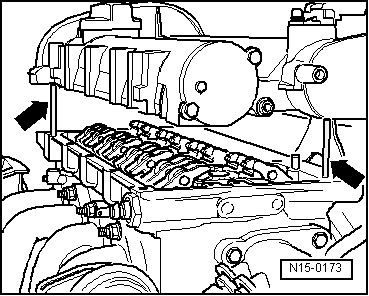

Caution | The studs (M6x80) must be screwed into cylinder head before installing camshaft housing. |

| The camshaft housing is guided by the studs, so that the roller rocker fingers do not slip off the supporting elements. |

|

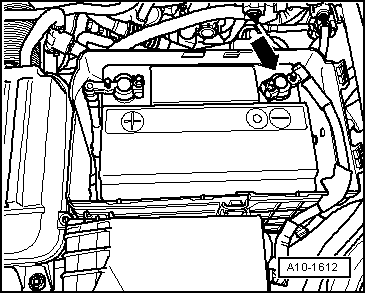

| Install in reverse order to dismantling, noting the following: |

| l

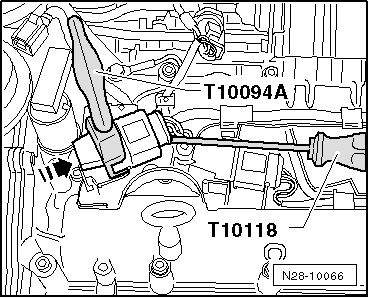

| Pistons must not be at TDC. |

Note | On turning the camshafts, the valves may hit the pistons if they are at TDC. |

| –

| Remove sealant remnants on cylinder head and camshaft housing with a commercially available sealant remover. |

| –

| Also prevent dirt and residual sealant from entering cylinder head. |

| –

| Clean sealing surfaces. They must be free of oil and grease. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution