| –

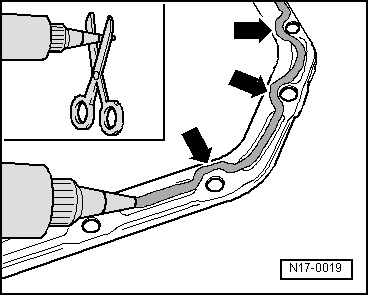

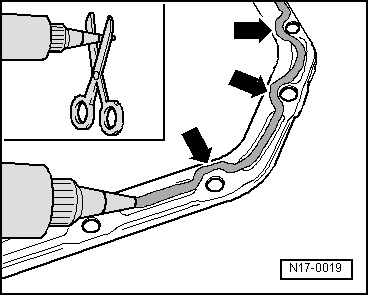

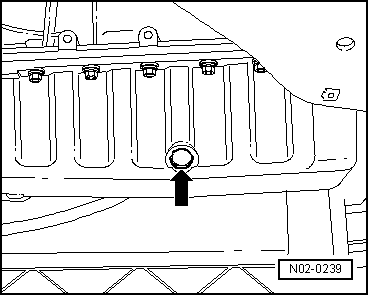

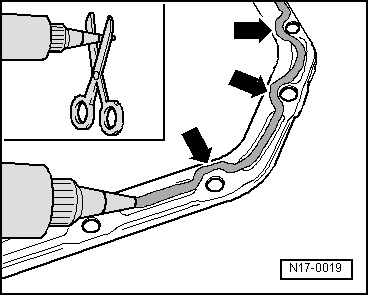

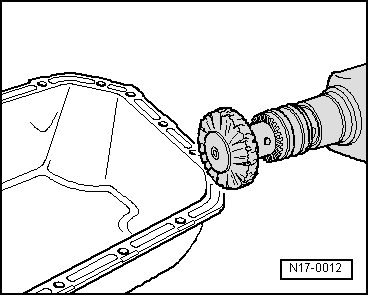

| Cut off tube nozzle at upper marking (nozzle approx. approx. 3 mm). |

| –

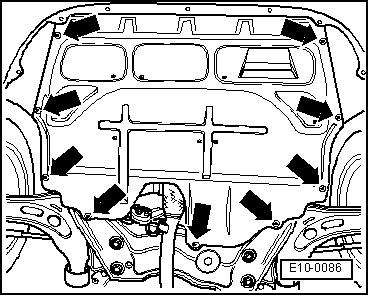

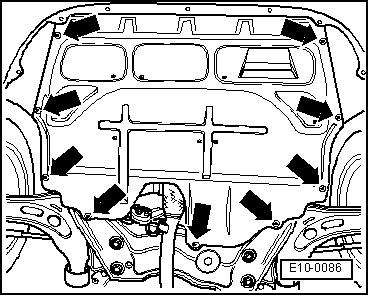

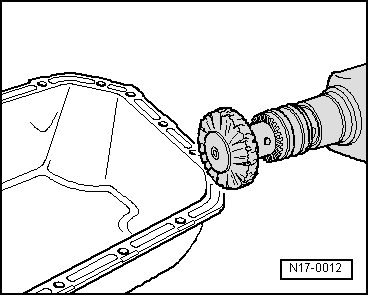

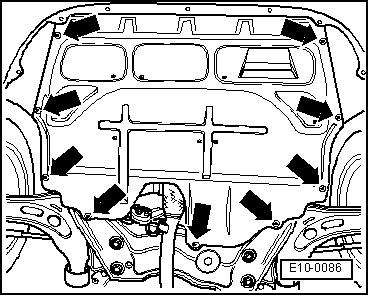

| Apply the silicone-based sealant to the clean contact surface of the oil sump, proceeding as shown. The strip of sealant must: |

| t

| pass next to the bolt holes, through the inner side -arrows-. |

Note | The sealant bead must not be thicker. Otherwise the excess sealant may enter the oil sump, and obstruct the strainer in the oil intake pipe. |

| –

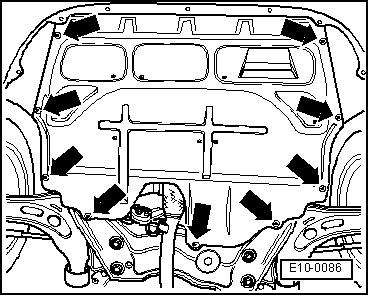

| Fit the oil sump immediately, tightening lightly all of the attachment bolts in diagonal pairs. |

| –

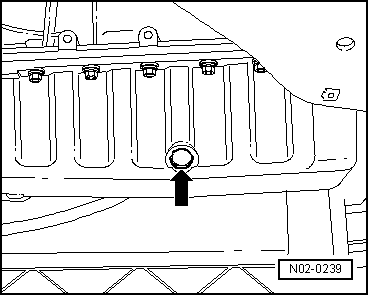

| Tighten the oil sump bolts in diagonal pairs to a torque of 15 Nm. |

Note | After installing the oil sump, the sealant must dry for approx. 30 minutes. Only then should the engine be refilled with oil. |

| Continue installation following reverse order for removing. |

| –

| Replenish engine oil and check oil level → Fig.. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note