Leon Mk1

|

| Special tools and workshop equipment required |

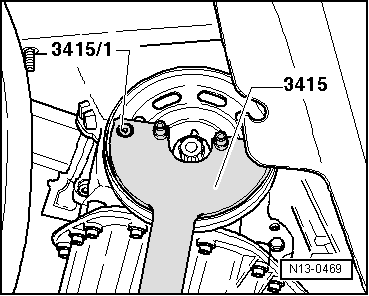

| t | Hose clamp -3415-, see equivalent → Anchor |

| t | Hose clamp -3415/1-, see equivalent → Anchor |

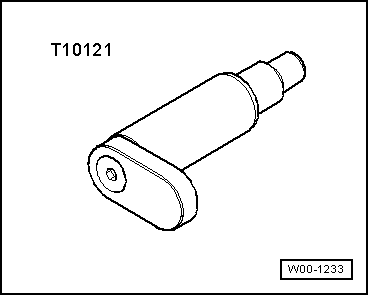

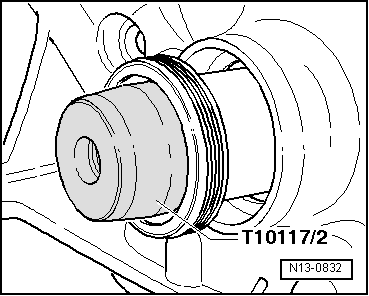

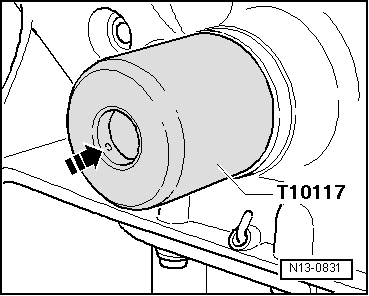

| t | Tappet -T10117-, see equivalent → Anchor |

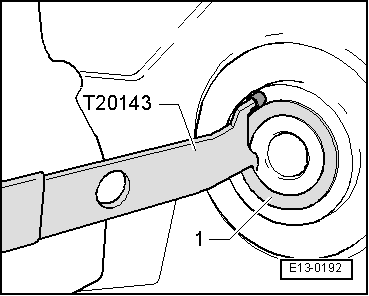

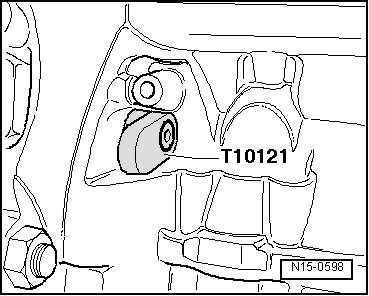

| t | Extractor kit -T20143-, see equivalent → Anchor |

| t | Torque wrench (40... 200 Nm) -V.A.G 1332-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|