Leon Mk1

| Crankshaft oil seal- pulley side: replace |

| Special tools and workshop equipment required |

| t | Torque wrench kit -SAT 8010- |

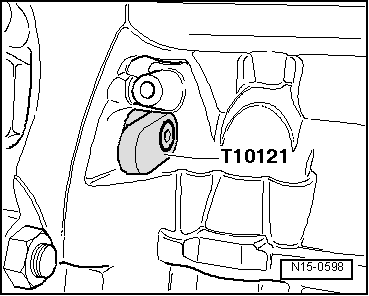

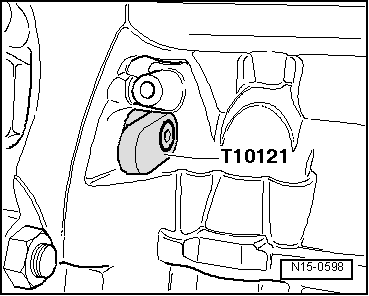

| t | Counterhold tool -T10121- |

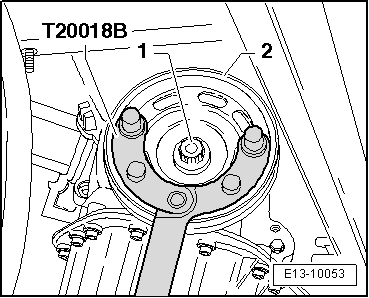

| t | Counterhold tool -T20018B- |

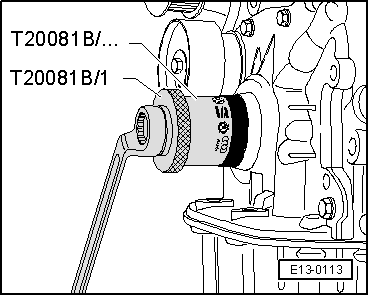

| t | Guide sleeve -T20081B- |

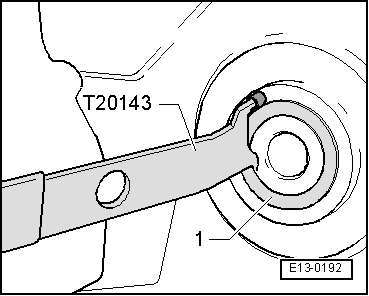

| t | Extractor kit -T20143- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

WARNING

WARNING