| –

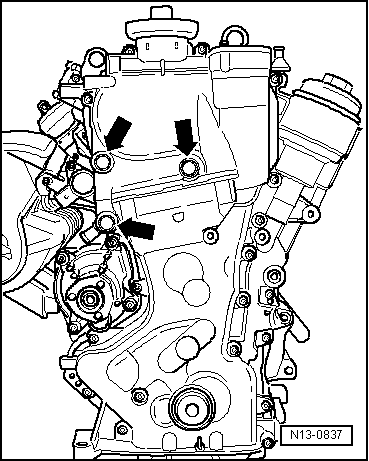

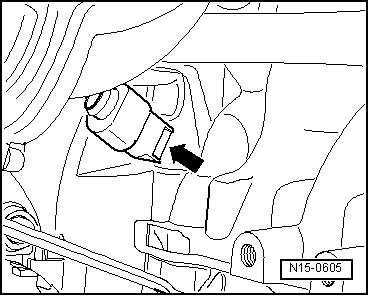

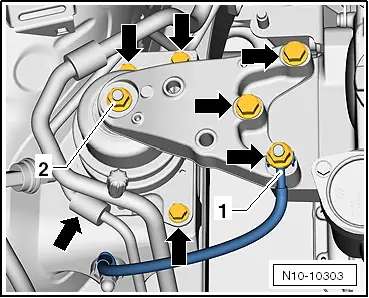

| Remove Allen keys from the distribution casing and the bolts marked with -arrows-. |

| –

| Remove distribution chain. |

Note | Note that crankshaft bearing bush remains in sealing flange. |

| –

| Clean sealing surfaces carefully. They must be free of oil and grease. |

| –

| Screw two stud -M6x80- into cylinder head and cylinder block to improve guidance. |

| –

| Apply a thin even coat of sealant D 174 003 A2 onto the clean sealing surface. |

| –

| Fit timing case with crankshaft bearing bush simultaneously onto studs, dowel pins and crankshaft journal. |

| –

| Tighten valve timing housing securing bolts evenly and diagonally. |

| Ensure that timing case is not canted. |

| –

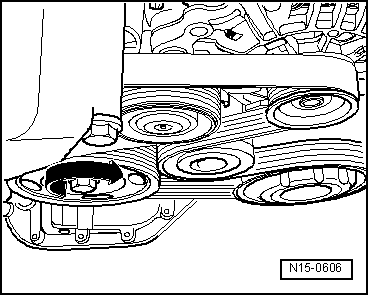

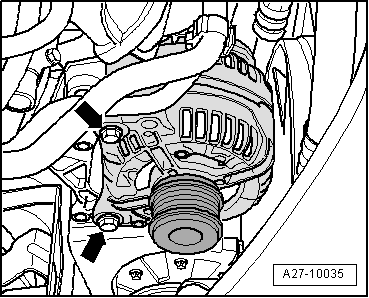

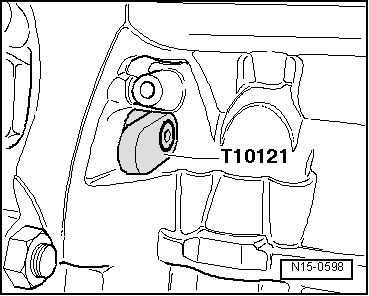

| Fit the belt pulley with a new fastening bolt. |

| –

| Tighten the fastening bolt as far as possible by hand. |

Note | Ensure that the pulley is not tilted during fitting. |

| –

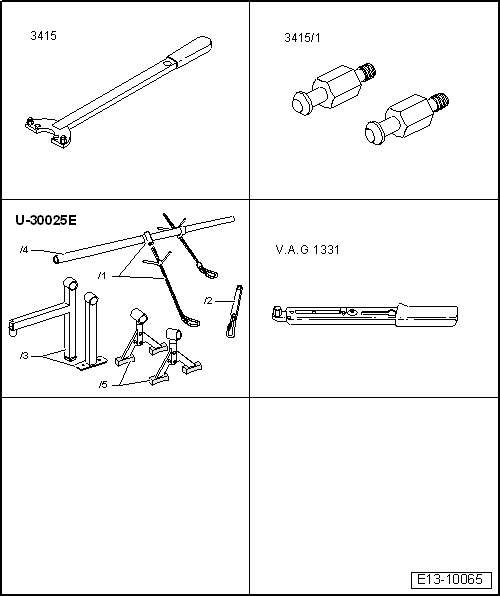

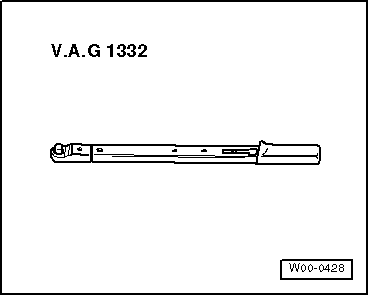

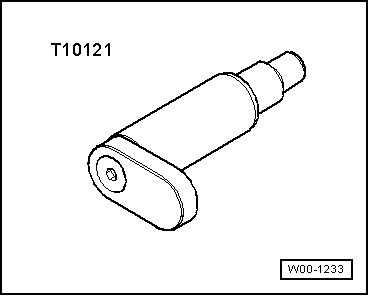

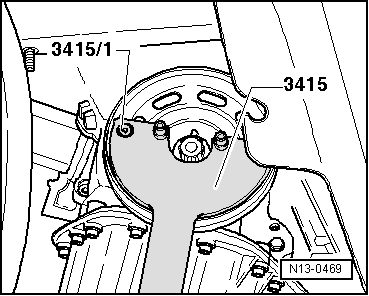

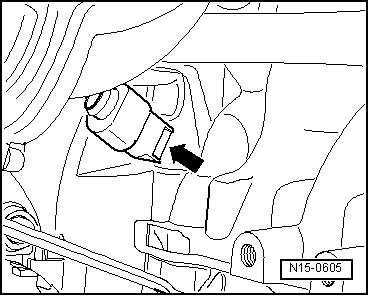

| Hold the pulley tight using the counterhold -3415- and -3415/1-. |

| Tightening torque: 150 Nm + turn 180° further |

|

|

|

Caution

Caution Note

Note