| –

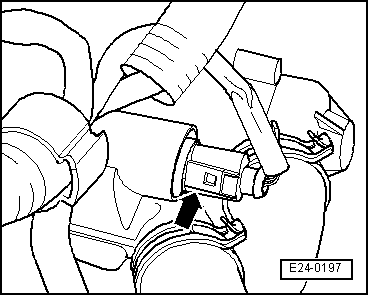

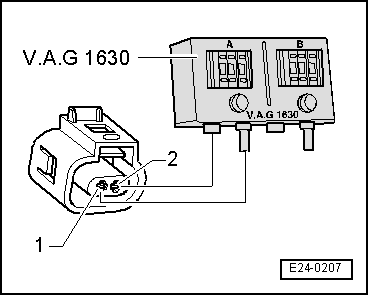

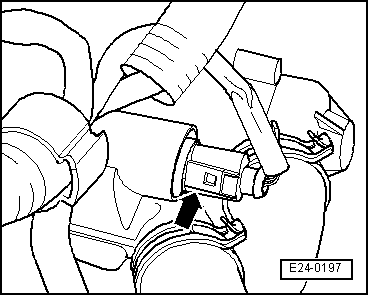

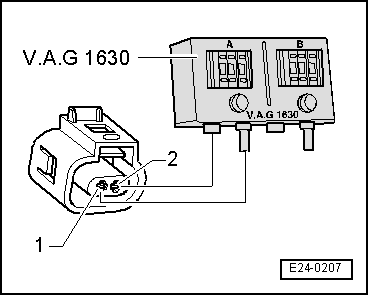

| Hold a small container under the injector to be checked and pull connectors off all other injectors. |

| –

| Have 2nd person operate starter. Injector must spray in pulses. |

| –

| Repeat check on the other injectors. In the process, take care that only the valve to be checked is connected. |

| –

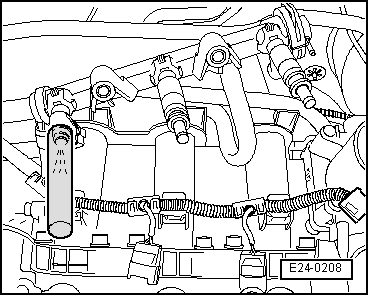

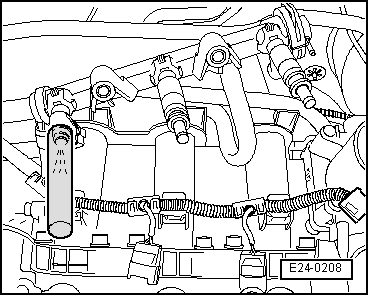

| Then check injectors for leaks. No more than 2 drops/min may leak out. |

| If the fuel loss is greater: |

| –

| Renew defective injector → Item. |

| Installation of the injectors is carried out in the reverse order to removal, observing the following: |

| t

| Renew O-rings on all injectors and lightly moisten with clean engine oil. |

| t

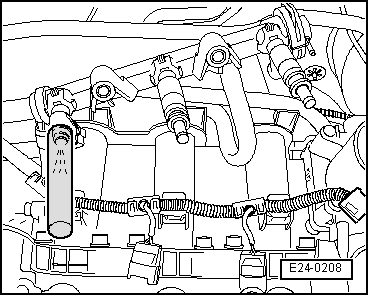

| Insert injectors vertically and in the correct position into the fuel rail and secure with retaining clips. |

| t

| Fit fuel rail to the cylinder head with all the injectors correctly placed and bolt uniformly. |

|

|

|