| –

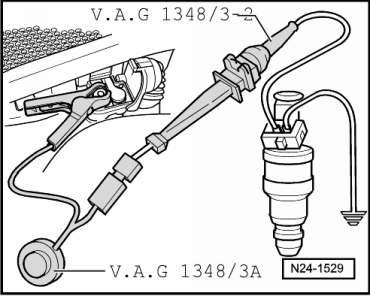

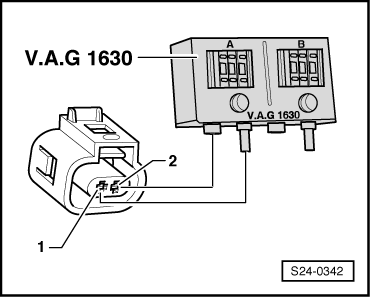

| Connect a contact of the valve to the earth terminal of the battery. |

| –

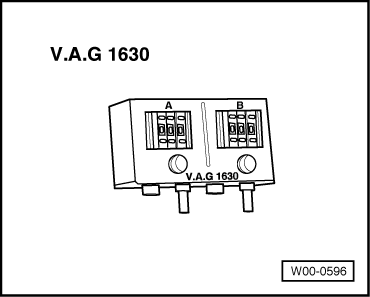

| Then connect the second contact of injector to the remote control. |

| –

| Connect the clamp to the positive (+) pole of the battery. |

| –

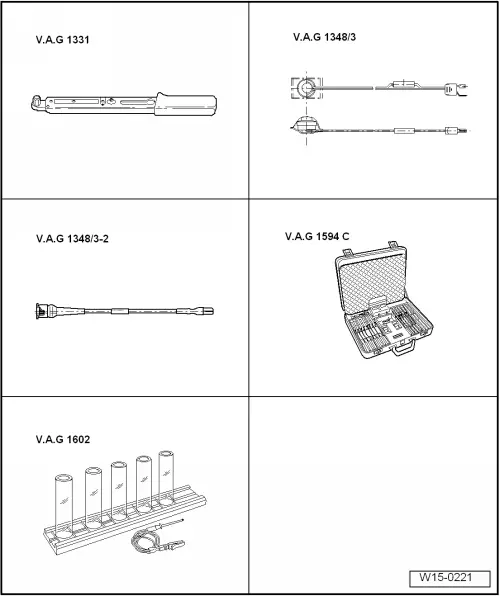

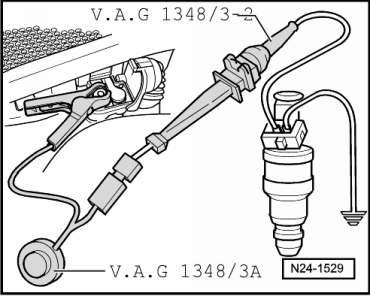

| To protect the battery positive (+) and fuse holder, connect using the test lead and adapter cable -V.A.G 1348/3-2-. |

| The fuel supply unit must run. |

| –

| Activate remote control for 30 seconds. |

| –

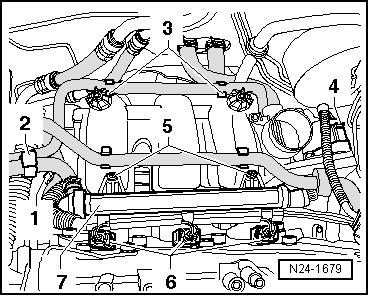

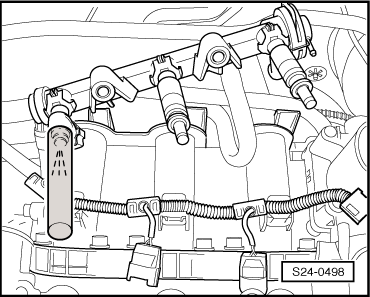

| Repeat the check on all other injectors. Always use a new measuring container. |

| –

| Once all injectors have been actuated, place the measuring container on a flat surface. |

| –

| Disconnect the voltage supply of the fuel delivery unit. |

| –

| Compare the injected quantities. |

| Specification: 85 ... 91 ml per injector. |

| If the measured values of one or more injectors are above or below the prescribed specifications: |

| Fit the injectors in the reverse order of removal. Note the following: |

| t

| Renew O-rings on all injectors and lightly moisten with clean engine oil. |

| t

| Fit fuel rail with secured injectors onto intake manifold and press in evenly. |

|

|

|

Note

Note

WARNING

WARNING