Leon Mk1

| Engine: dismounting |

| Special tools and workshop equipment required |

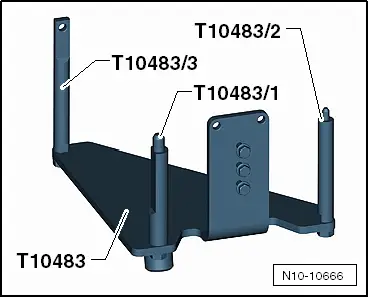

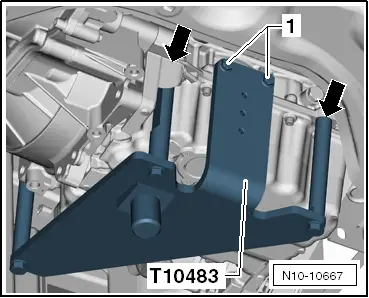

| t | Engine support -T10483- |

| t | Drip tray for workshop hoist -VAS 6208- |

| t | Engine and gearbox support -VAS 6095- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Hose clip pliers -VAS 6340- |

| t | Stepladder -VAS 5085- (not illustrated) |

| t | Adapter -T10480- (not illustrated) |

Note

Note

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

WARNING

WARNING Caution

Caution